What is the Cleanroom HVAC Market Size?

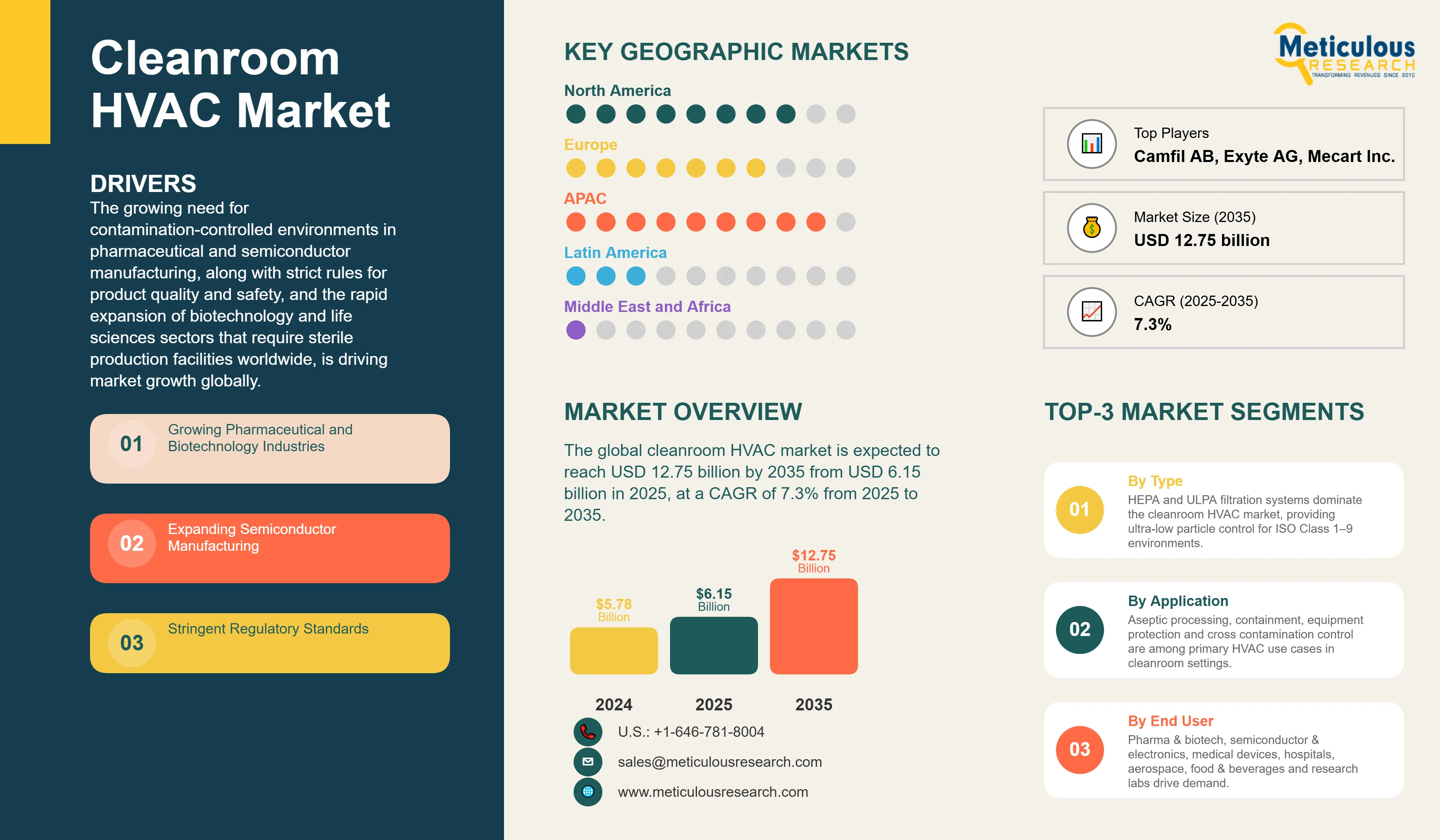

The global cleanroom HVAC market was valued at USD 5.78 billion in 2024 and is expected to reach USD 12.75 billion by 2035 from USD 6.15 billion in 2025, at a CAGR of 7.3% from 2025 to 2035.

The growing need for contamination-controlled environments in pharmaceutical and semiconductor manufacturing, along with strict rules for product quality and safety, and the rapid expansion of biotechnology and life sciences sectors that require sterile production facilities worldwide, is driving market growth globally.

Cleanroom HVAC Market Key Takeaways

- In terms of revenue, the global cleanroom HVAC market is valued at USD 6.15 billion in 2025 and is projected to reach USD 12.75 billion by 2035.

- The market is expected to grow at a CAGR of 7.3% from 2025 to 2035.

- Asia Pacific dominates the global cleanroom HVAC market with the largest market share of 40-45% in 2025.

- North America is expected to witness the fastest CAGR during the forecast period.

- By filter type, the HEPA filters segment holds the largest share of 60-65% in 2025.

- By filter type, the ULPA filters segment is expected to witness the fastest CAGR from 2025 to 2035.

- By system type, the recirculating air systems segment holds the largest market share of 70% in 2025.

- By system type, the unidirectional flow systems segment is expected to witness the fastest CAGR during the forecast period.

- By component, the fan filter units (FFU) segment holds the largest share of 35% in 2025.

- By component, the air handling units segment is expected to witness the fastest CAGR through 2035.

- By cleanroom class, the ISO Class 5-6 segment holds the largest share of 35-40% in 2025.

- By cleanroom class, the ISO Class 1-4 segment is expected to witness the fastest CAGR through 2035.

- By end user, the pharmaceutical & biotechnology segment accounts for the significant market share of 35-40% in 2025.

- By end user, the medical devices segment is expected to witness the fastest CAGR during the forecast period.

Market Overview and Insights

Click here to: Get Free Sample Pages of this Report

The cleanroom HVAC market involves designing, manufacturing, installing, and maintaining specialized heating, ventilation, and air conditioning systems. These systems create and uphold controlled environments with specific levels of airborne particles, temperature, humidity, and pressure. They include high-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filters, precise airflow controls, and advanced monitoring systems to reach cleanliness levels from ISO Class 1 to ISO Class 9.

The cleanroom HVAC market is driven by the growing pharmaceutical and biopharmaceutical sectors needing sterile environments, increased demand in semiconductor production for ultra-clean conditions, rising concerns about healthcare-associated infections that lead to more hospitals adopting cleanrooms, technological improvements in energy-efficient filtration and airflow management, and stricter regulatory standards for good manufacturing practices (GMP) in various industries.

What are the Key Trends in the Cleanroom HVAC Market?

- Energy-efficient and sustainable cleanroom design: A major trend in the cleanroom HVAC market is the use of energy-saving technologies, including EC motors, heat recovery systems, and demand-controlled filtration to lower the high energy consumption of cleanroom operations. Low-pressure-drop filters, optimized airflow patterns, and variable air volume systems cut energy use while keeping the necessary cleanliness levels. Green building certifications and corporate sustainability goals encourage the use of renewable energy and carbon-neutral cleanroom designs. Some facilities achieve a 40-50% reduction in energy compared to traditional systems.

- Modular and flexible cleanroom solutions: Another key trend boosting market growth is the creation of modular, prefabricated cleanroom systems with integrated HVAC that can be quickly set up and adjusted. These solutions include plug-and-play HVAC components, standardized interfaces, and scalable designs that meet changing production needs. Modular systems cut installation time by 50-70% and allow for phased expansion. This is especially attractive to startups and companies needing flexible manufacturing spaces for personalized medicine and small-batch production.

Market Scope

|

Report Coverage

|

Details

|

|

Market Size by 2035

|

USD 12.75 Billion

|

|

Market Size in 2025

|

USD 6.15 Billion

|

|

Market Size in 2024

|

USD 5.78 Billion

|

|

Market Growth Rate from 2025 to 2035

|

CAGR of 7.3%

|

|

Dominating Region

|

Asia Pacific

|

|

Fastest Growing Region

|

North America

|

|

Base Year

|

2024

|

|

Forecast Period

|

2025 to 2035

|

|

Segments Covered

|

Filter Type, System Type, Component, Cleanroom Class, Application, End User, and Region

|

|

Regions Covered

|

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa

|

Market Dynamics

Drivers

Pharmaceutical and Biotechnology Industry Expansion

A key reason for the growth of the cleanroom HVAC market is the rapid rise of the pharmaceutical and biotechnology sectors. This is especially true for biologics, cell and gene therapies, and personalized medicine, which require strict contamination control. The global biologics market is expected to hit $500 billion by 2030. It needs sterile manufacturing environments with ISO Class 5 or better conditions for aseptic processing.

The COVID-19 pandemic emphasized the urgent need for vaccine production capacity, leading to increased investments in new cleanroom facilities around the world. Regulatory requirements, including the FDA's current Good Manufacturing Practice (cGMP) and EU GMP Annex 1, set specific HVAC performance standards for pharmaceutical cleanrooms.

The move toward continuous manufacturing and single-use technologies in biopharmaceuticals creates new HVAC needs for flexible, modular facilities. A growing focus on preventing drug shortages and ensuring supply chain stability is pushing the expansion of pharmaceutical manufacturing capacity, especially in developed markets that want to lessen their reliance on imports.

Opportunity

Emerging Markets and Advanced Manufacturing

The growth of pharmaceutical and electronics manufacturing in emerging markets offers strong opportunities for cleanroom HVAC systems as countries improve their local production capabilities. Government programs encouraging local pharmaceutical production in India, China, Brazil, and some African countries create a need for GMP-compliant cleanroom facilities. The rise of new therapies like CAR-T cells, gene editing, and regenerative medicine requires specialized cleanroom environments with specific HVAC needs.

Increased investments in semiconductor manufacturing, driven by chip shortages and local supply chains, require very clean environments with specialized HVAC systems. The legalization and regulation of the cannabis industry in various areas also creates a new need for controlled environment cultivation and processing facilities.

The development of sustainable cleanroom technologies, such as energy recovery, renewable energy use, and low-GWP refrigerants, appeals to organizations that prioritize environmental responsibility.

Filter Type Insights

Why do HEPA Filters Dominate the Market?

The HEPA filters segment holds the largest share of around 65% of the overall cleanroom HVAC market in 2025. HEPA filters remove 99.97% of particles that are 0.3 microns or larger, meeting the needs of many cleanroom applications including pharmaceutical manufacturing, electronics assembly, and healthcare facilities.

The common availability of HEPA filters and their established performance standards (EN 1822, IEST-RP-CC001) ensure consistent quality and compliance with regulations. HEPA filtration strikes a good balance between achieving cleanliness and keeping operational costs low for ISO Class 5-8 cleanrooms, which make up most installations.

However, the ULPA filters segment is expected to grow at the fastest CAGR through 2035. A rising need for ISO Class 1-4 cleanrooms, especially in semiconductor manufacturing and nanotechnology, drives the use of ULPA filters, which remove 99.999% of particles that are 0.12 microns or larger. Advanced pharmaceutical applications, such as sterile injectables and cell therapies, increasingly require ULPA filtration in critical areas.

System Type Insights

How do Recirculating Air Systems Support Cleanroom Operations?

The recirculating air systems segment holds the largest market share at nearly 70% in 2025. Recirculating systems, which reuse filtered air, can cut energy use by 30-50% compared to single-pass systems, leading to substantial savings in operating costs. These systems maintain stable temperature and humidity with recirculated air, which enhances process control and product quality in manufacturing. Recirculating designs meet required air change rates (20-600 per hour) more cost-effectively by filtering and returning room air instead of conditioning outdoor air.

The unidirectional flow systems segment is expected to grow the fastest in the coming years. Critical manufacturing processes that need ISO Class 1-5 environments drive the use of unidirectional (laminar) flow systems, which provide steady and contamination-free airflow. The growing demand for unidirectional flow in advanced semiconductor fabrication and aseptic pharmaceutical processing aims to protect products.

End User Insights

Why do Pharmaceutical & Biotechnology Lead Market Demand?

Based on end user, the pharmaceutical and biotechnology segment commands the largest share of around 40% of the overall cleanroom HVAC market in 2025. Strict rules for drug manufacturing, including FDA 21 CFR Part 211 and EU GMP, require controlled environments with validated HVAC systems. The complexity of producing biological drugs, which needs multiple cleanroom areas with different classifications, drives the need for advanced HVAC setups.

The growth of contract manufacturing organizations (CMOs) and contract development and manufacturing organizations (CDMOs) further drives the need for cleanroom capacity. The push for personalized medicine and small-batch production requires flexible cleanroom designs with improved HVAC features. Regular inspections and quality audits lead to ongoing investments in cleanroom HVAC maintenance and upgrades.

However, the medical devices segment is expected to experience the fastest growth during the coming years. The increasing complexity of medical devices, such as implantables, drug-device combinations, and diagnostic equipment, heightens the need for cleanrooms.

U.S. Cleanroom HVAC Market Size and Growth 2025 to 2035

The U.S. cleanroom HVAC market is projected to be worth around USD 3.92 billion by 2035, growing at a CAGR of 7.8% from 2025 to 2035.

How is the Asia Pacific Cleanroom HVAC Market Growing Dominantly Across the Globe?

Asia Pacific holds the largest share of 40-45% of the global cleanroom HVAC market in 2025. This is primarily attributed to its vast semiconductor manufacturing capacity in Taiwan, South Korea, China, and Japan. These countries need advanced cleanroom HVAC systems for chip production.

Rapid growth in the pharmaceutical industry in India and China, fueled by domestic demand and export opportunities, creates significant needs for cleanroom infrastructure. Government programs like "Make in India" for pharmaceuticals and China's plans for developing the biomedical industry promote investments in cleanroom facilities.

The region's role as the global electronics manufacturing hub requires many cleanroom facilities for producing and assembling components. Lower construction and operational costs than those in Western markets attract multinational companies looking to set up cleanroom facilities. The growing biotechnology sectors in Singapore, South Korea, and China focus on biosimilars and innovative therapies, which increases demand for cleanrooms.

Which Factors Support the North America Cleanroom HVAC Market Growth?

North America is set to experience the fastest growth rate from 2025 to 2035. This growth comes from significant investments in biopharmaceutical manufacturing, including cell and gene therapies that need specialized cleanroom environments.

Reshoring initiatives for pharmaceutical and semiconductor manufacturing, which gained urgency due to supply chain issues highlighted by COVID-19, are increasing the demand for cleanroom facilities.

A strong regulatory system and enforcement from the FDA lead to ongoing updates and maintenance of cleanroom HVAC systems. The presence of top pharmaceutical, biotechnology, and medical device companies spurs innovation in cleanroom technology.

Government support through the CHIPS Act for semiconductor manufacturing and BARDA for pharmaceutical readiness aids the development of cleanroom infrastructure. Leading research facilities in universities and national labs need state-of-the-art cleanroom HVAC systems for nanotechnology and life sciences research.

Value Chain Analysis

- Component Manufacturing and Technology Development This stage focuses on developing filters, fans, sensors, controls, and other components optimized for cleanroom HVAC applications. Key Players: Camfil AB, AAF International, Trane Technologies, Carrier Global Corporation

- System Design and Integration This stage involves engineering complete cleanroom HVAC solutions, integrating components, and providing installation and validation services.

Key Players:

- PBSC Cleanrooms

- Swiftwall Inc.

- Atmos-Tech Industries

- Clean Rooms International Inc.

- E.J. Pleune Company

- ABN Cleanroom Technology

- Weiss Technik

- Suzhou Pharma Machinery Co. Ltd.

- Airtech Japan Ltd.

- Nicomac Clean Rooms

- Ardmac Ltd.

- Mecart Inc.

- Terra Universal Inc.

- Clean Air Technology Inc.

- Exyte AG

- M+W Group

- Carrier Global Corporation

- Trane Technologies plc

- AAF International (Daikin Industries)

- Camfil AB

Recent Developments

- March 2025 — Camfil launched enhancements to its Hi-Flo air filtration products, improving energy efficiency by 12% to meet updated European ventilation standards for cleanrooms and critical facilities. Camfil also highlighted advanced HEPA filters with low pressure drops optimized for data centers and semiconductor cleanrooms.

- February 2025 — Getek (GE Technology) launched the CHEMSORB-R Series chemical filtration solutions specifically designed for critical HVAC systems in semiconductor and cleanroom environments, with modular trays and tool-free maintenance for VOC and AMC capture

Segments Covered in the Report

By Filter Type

- HEPA Filters (High-Efficiency Particulate Air)

- ULPA Filters (Ultra-Low Particulate Air)

- Pre-Filters

- Carbon Filters

- Others

By System Type

- Recirculating Air Systems

- Single Pass Systems

- Unidirectional Flow Systems

- Mixed Flow Systems

By Component

- Air Handling Units (AHU)

- Fan Filter Units (FFU)

- Laminar Air Flow Units

- Air Diffusers

- Air Showers

- Pass Boxes

- Cooling Coils

- Humidifiers/Dehumidifiers

- Ducting

- Others

By Cleanroom Class

- ISO Class 1-4

- ISO Class 5-6

- ISO Class 7-8

- ISO Class 9

By Application

- Aseptic Processing

- Containment

- Process Equipment Protection

- Product Protection

- Cross-Contamination Control

By End User

- Pharmaceutical & Biotechnology

- Medical Devices

- Semiconductor & Electronics

- Hospitals & Healthcare

- Food & Beverage

- Aerospace & Defense

- Automotive

- Research Laboratories

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

Frequently Asked Questions