Resources

About Us

Modified Plastics Market Size, Share, Forecast & Trends Analysis By Product Type (Polypropylene, ABS, Polycarbonate, Polyamide, Polyethylene, PBT, PPO), Modification Type (Filled, Reinforced, Blended/Alloyed, Flame Retardant), Application (Automotive, Electronics, Consumer Goods, Construction, Packaging, Industrial Equipment) — Global Forecast to 2035

Report ID: MRCHM - 1041628 Pages: 230 Dec-2025 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportWhat is the Modified Plastics Market Size?

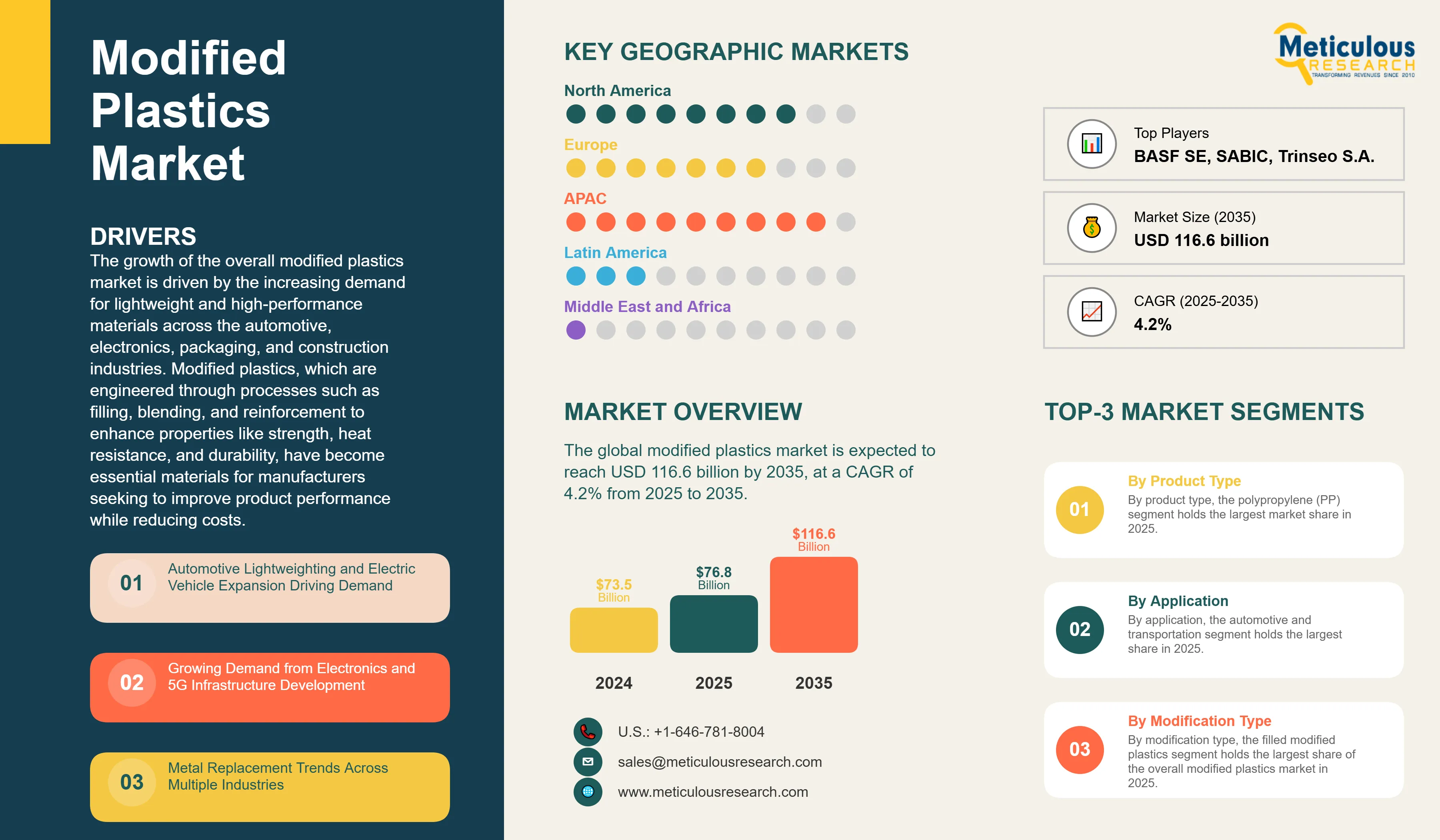

The global modified plastics market was valued at USD 73.5 billion in 2024. This market is expected to reach USD 116.6 billion by 2035 from USD 76.8 billion in 2025, at a CAGR of 4.2% from 2025 to 2035. The growth of the overall modified plastics market is driven by the increasing demand for lightweight and high-performance materials across the automotive, electronics, packaging, and construction industries. Modified plastics, which are engineered through processes such as filling, blending, and reinforcement to enhance properties like strength, heat resistance, and durability, have become essential materials for manufacturers seeking to improve product performance while reducing costs. The shift of the automotive industry toward electric vehicles and lightweighting initiatives, coupled with stringent environmental regulations promoting recyclable and sustainable materials, continues to fuel significant growth of this market across all major geographic regions.

Market Highlights: Modified Plastics

In terms of revenue, the global modified plastics market is valued at USD 76.8 billion in 2025 and is projected to reach USD 116.6 billion by 2035.The market is expected to grow at a CAGR of 4.2% from 2025 to 2035.

Asia Pacific dominates the global modified plastics market with the largest market share in 2025.

Asia Pacific is expected to witness the fastest CAGR during the forecast period.

By product type, the polypropylene (PP) segment holds the largest market share in 2025.

By product type, the polycarbonate (PC) segment is expected to witness the fastest growth during the forecast period.

By modification type, the filled modified plastics segment holds the largest share of the overall modified plastics market in 2025.

By modification type, the reinforced modified plastics segment is expected to witness the fastest CAGR during the forecast period.

By application, the automotive and transportation segment holds the largest share in 2025.

By application, the electronics and electrical segment is expected to witness the fastest CAGR during the forecast period.

Click here to: Get Free Sample Pages of this Report

Modified plastics are engineered polymer materials that have been enhanced through various modification techniques to achieve superior performance characteristics compared to standard base polymers. These modifications include filling (adding mineral or glass fillers), blending (combining different polymers), reinforcement (incorporating glass or carbon fibers), and functional modifications such as flame retardancy, UV stabilization, and impact resistance enhancement. The resulting materials offer a versatile combination of mechanical strength, thermal stability, chemical resistance, and processability that makes them indispensable across numerous industrial applications.

The market includes a diverse range of modified polymer types, including modified polypropylene (PP), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polyamide (PA/Nylon), polyethylene (PE), and various engineering plastic alloys such as PC/ABS blends. These materials are processed using techniques including injection molding, extrusion, blow molding, and thermoforming to produce components for automotive interiors and exteriors, electronic device housings, appliance components, construction materials, and packaging solutions. The ability to tailor material properties to specific application requirements has made modified plastics the material of choice for designers and engineers seeking optimal performance-to-cost ratios.

The overall modified plastics market is expected to witness robust growth during the forecast period, driven by several factors. The automotive industry is pushing hard to make vehicles lighter, aiming to boost fuel efficiency and cut emissions. This drive has sped up the shift from metal to plastic parts, with advanced modified plastics helping reduce component weights by 30-50%, all while keeping the strength and safety standards intact. At the same time, the rapid growth in the electric vehicle market is increasing the need for specialized modified plastics. These materials offer crucial features like better heat management, electrical insulation, and flame resistance to support batteries and charging systems. Meanwhile, the consumer electronics industry continues to shrink devices and enhance performance, leading to wider use of engineering-grade modified plastics that provide stable dimensions, efficient heat dissipation, and protection against electromagnetic interference.

What are the Key Trends in the Modified Plastics Market?

Sustainability and Circular Economy Initiatives

A major trend reshaping the modified plastics market is the commitment of this industry to sustainability and circular economy principles. Manufacturers are increasingly developing modified plastics that include recycled content, bio-based feedstocks, and designs aimed at improving recyclability. Leading companies are investing heavily in recycling technologies, such as chemical recycling and dissolution processes, that allow the recovery and reuse of modified plastics without degrading material properties. The creation of bio-based modified plastics using renewable feedstocks like plant-derived polymers marks a key innovation pathway. Manufacturers are producing items that maintain performance while reducing reliance on petroleum-based materials. Regulatory pressures, especially in Europe and North America, are speeding up this transition through extended producer responsibility programs, recycled content mandates, and carbon pricing that support sustainable material choices.

Advanced Material Development for Electric Vehicles and 5G Applications

Another major trend transforming the market is the development of modified plastics designed for new technology applications. The electric vehicle revolution needs materials with specific property combinations, including high thermal conductivity for battery thermal management, flame retardancy that meets strict UL94 V-0 ratings, and electrical insulation properties that ensure safety and reliability. Modified plastics are being created with special additives and reinforcements that meet these needs while allowing for lightweight construction, which is crucial for maximizing vehicle range. Likewise, the global rollout of 5G telecommunications infrastructure requires modified plastics with carefully controlled dielectric properties, low signal loss characteristics, and great dimensional stability for antenna housings, radomes, and electronic enclosures. These high-performance materials command premium pricing and offer significant growth opportunities for specialty compounders with advanced formulation skills.

The global modified plastics market was valued at USD 73.5 billion in 2024. This market is expected to reach USD 116.6 billion by 2035 from USD 76.8 billion in 2025, at a CAGR of 4.2% from 2025 to 2035.

|

Report Coverage |

Details |

|

Market Size by 2035 |

USD 116.6 Billion |

|

Market Size in 2025 |

USD 76.8 Billion |

|

Market Size in 2024 |

USD 73.5 Billion |

|

Market Growth Rate from 2025 to 2035 |

CAGR of 4.2% |

|

Dominating Region |

Asia Pacific |

|

Fastest Growing Region |

Asia Pacific |

|

Base Year |

2024 |

|

Forecast Period |

2025 to 2035 |

|

Segments Covered |

Product Type, Modification Type, Application, and Region |

|

Regions Covered |

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Automotive Lightweighting and Electric Vehicle Expansion Driving Demand

A key driver of the modified plastics market is the fast-tracking movement of the automotive industry toward lightweight materials and electric vehicle manufacture. Global regulations requiring better fuel economy and lower carbon emissions have created significant incentives for the replacement of traditional metal parts with high-performance modified plastics in automaker designs. The U.S. Corporate Average Fuel Economy (CAFE) standards, European Union CO2 emission targets, and China's dual-credit policy drive manufacturers toward lightweighting solutions that modified plastics can uniquely provide. It is estimated that for every 10% reduction in vehicle weight, there is a corresponding improvement of about 6-8% in fuel efficiency; therefore, modified plastics, with their weight advantage of 30-50% over metals, are considered a crucial enabler of compliance strategies.

The electric vehicle segment is a very specific driver of growth for modified plastics. Battery electric vehicles will have specific needs for thermal management, electrical insulation, and flame retardancy in battery enclosures, module housings, and charging components. The growth of the global EV battery market to support more than 40 million annual electric vehicle sales by 2030 will directly influence the usage of high-performance modified engineering plastics. Furthermore, the need for extending the range of electric vehicles heightens demand for light material applications throughout vehicle manufacture, from interior paneling to exterior body parts.

Opportunity

Expansion in Electronics and 5G Infrastructure to Create New Demand

The rapid growth of consumer electronics, industrial automation, and telecommunications infrastructure provides great opportunities for the modified plastics market. Indeed, the global roll-out of 5G networks has created a compelling demand for value-added modified plastics in antenna systems, radomes, base station housings, and small cell enclosures. All these applications require low dielectric constants, very low signal loss, excellent weatherability, and good dimensional stability-all attributes that can be met with advanced modified plastics. According to Meticulous Research, the 5G infrastructure market is set to surpass USD 150 billion through 2032, with modified plastics poised for an expanding share of the materials content as network densification requires the installation of millions of small cells.

Continued innovation by the consumer electronics industry in smartphones, tablets, wearables, and smart home devices is driving the demand for engineering-grade modified plastics that enable thin-wall designs, premium aesthetics, and functional integration. The miniaturization trends drive the need for materials with exceptional flowability to accommodate complicated mold geometries without sacrificing mechanical properties and dimensional precision. Advanced features of electronic devices, such as wireless charging, 5G connectivity, and biometric sensors, create opportunities for modified plastics with value-added electromagnetic, thermal conductivity, and surface characteristics. Finally, the increasing demand for data centers that power cloud computing and artificial intelligence applications is stimulating demand for modified plastics in server housings, cable management systems, and cooling infrastructure.

Product Type Insights

Why Does Polypropylene (PP) Dominate the Market?

The modified polypropylene (PP) segment accounts for around 30-35% of the overall modified plastics market in 2025. This dominant position reflects polypropylene's exceptional versatility, cost-effectiveness, and broad applicability across multiple end-use industries. Modified PP compounds offer an optimal balance of mechanical properties, chemical resistance, and processability that makes them the material of choice for high-volume automotive applications including bumpers, interior trim, instrument panels, and under-hood components. The automotive industry alone consumes over 40% of modified PP production, with each vehicle containing an average of 25-30 kilograms of polypropylene-based materials.

However, the modified polycarbonate (PC) segment is expected to grow at the fastest CAGR during the forecast period, driven by expanding applications in electronics, automotive lighting, and medical devices. Polycarbonate's optical clarity, impact resistance, and dimensional stability make it essential for LED lighting lenses, electronic device housings, and automotive headlamp assemblies. The transition to LED lighting in both automotive and general illumination markets has significantly increased demand for optical-grade modified PC compounds.

Application Insights

How Does Automotive and Transportation Lead the Market?

Based on application, the automotive and transportation segment holds the largest share of the overall modified plastics market in 2025, accounting for around 35-40% of total consumption. From dashboards and door panels to seat components, bumpers, grilles, and mirror housings, the use of modified plastics in the automotive sector extends to all aspects: interior, exterior, and under-hood. Current vehicles have 150 to 200 kgs of plastic material, and with higher performance needs, the proportion of modified plastics is also increasing.

The electronics and electrical segment would see the fastest growth during the forecast period owing to the growing use of consumer electronics, expansion in 5G telecommunications infrastructure, and industrial equipment digitalization. Modified plastics are finding critical applications in the housing of electronic devices that have to face electromagnetic interference, in thermal management components used in power electronics, and in precision connectors that have to exhibit dimensional stability. The miniaturization of electronic devices starts pushing up the requirement for the high-flow varieties of modified engineering plastics that allow thin-wall molding with maintained structural integrity and heat resistance.

Regional Insights

How is Asia Pacific Maintaining Dominance in the Global Modified Plastics Market?

Asia Pacific holds the largest share of the global modified plastics market in 2025. The largest share of this region is primarily attributed to the concentration of manufacturing activity, particularly in automotive, electronics, and appliance industries that are major consumers of modified plastics. China alone accounts for more than half of regional consumption, with its position as the world's largest automotive market, electronics manufacturing hub, and appliance producer driving sustained growth. The presence of leading modified plastics manufacturers including Kingfa Science & Technology Co. Ltd., Shanghai Pret Composites Co. Ltd., and numerous specialized compounders provides a well-developed supply chain serving regional and global customers.

Japan and South Korea also contribute significantly to this market through their advanced automotive and electronics industries that demand high-performance engineering plastics. Japanese automakers' global production networks and Korean electronics giants' manufacturing operations create substantial consumption of premium modified plastics for demanding applications. India represents the fastest-growing market within Asia Pacific, driven by expansion of its automotive industry, growth of consumer appliance markets, and increasing domestic modified plastics production capacity. Southeast Asian countries including Thailand, Vietnam, and Indonesia are emerging as key markets as manufacturing activity relocates from China and domestic industries develop.

Which Factors Support North America and Europe Modified Plastics Market Growth?

Together, North America and Europe account for around 35 to 40% of global modified plastics market. The growth of these markets is mainly driven by the need for advanced manufacturing, especially in developing sustainable materials and electric vehicles. The demand for modified plastics in the North America is mainly due to its large automotive production base. Domestic modified plastics production is correspondingly strong in the U.S., benefiting from the country's position as a leading producer of specialty chemicals and other high-performance materials, including from BASF SE, Celanese Corporation, and DuPont de Nemours Inc. among others.

The leadership in sustainable materials development of modified plastics, stringent regulatory requirements, and premium automotive manufacturing characterize the market of modified plastics in Europe. Various European Union regulations on the circular economy, such as those on recycled content and extended producer responsibility, spur innovation in recyclable modified plastics and related compounds that have post-consumer recycled content. Leadership in luxury automotive manufacturing in the region creates demand for high-quality surface aesthetics and premium material properties with commensurate price premiums. Germany accounts for the largest market share of modified plastics in Europe due to its leading position in the automotive and industrial machinery sectors.

U.S. Modified Plastics Market Size and Growth 2025 to 2035

The U.S. modified plastics market is projected to grow at a CAGR of 3.2% from 2025 to 2035. The U.S. is the largest market in North America, driven by its extensive automotive manufacturing sector, advanced electronics industry, and robust construction activity. The presence of major automotive OEMs and their tier supplier networks in Michigan, Ohio, and the Southern states creates concentrated demand for modified plastics. Additionally, the U.S. market benefits from strong domestic compounding capacity and the headquarters presence of global materials companies including Celanese Corporation, DuPont de Nemours Inc., and Avient Corporation among others.

Key Players

The major players operating in the global modified plastics market include BASF SE (Germany), Kingfa Science & Technology Co. Ltd. (China), Shanghai Pret Composites Co. Ltd. (China), SABIC (Saudi Arabia), LG Chem Ltd. (South Korea), Covestro AG (Germany), Celanese Corporation (U.S.), DuPont de Nemours Inc. (U.S.), Mitsubishi Chemical Corporation (Japan), Asahi Kasei Corporation (Japan), LyondellBasell Industries N.V. (Netherlands), Trinseo S.A. (Luxembourg), Avient Corporation (U.S.), RTP Company (U.S.), Polyplastics Co. Ltd. (Japan), Lotte Chemical Corporation (South Korea), Ensinger GmbH (Germany), Dawn Polymer Co. Ltd. (China), Wanhua Chemical Group Co. Ltd. (China), and China XD Plastics Co. Ltd. (China), among others.

Segments Covered in the Report

By Product Type

By Modification Type

By Application

By Region

The modified plastics market is expected to grow from USD 76.8 billion in 2025 to USD 116.6 billion by 2035.

The modified plastics market is expected to grow at a CAGR of 4.2% from 2025 to 2035.

The major players in the modified plastics market include BASF SE, Kingfa Science & Technology Co. Ltd., Shanghai Pret Composites Co. Ltd., SABIC, LG Chem Ltd., Covestro AG, Celanese Corporation, DuPont de Nemours Inc., Mitsubishi Chemical Corporation, Asahi Kasei Corporation, LyondellBasell Industries N.V., Trinseo S.A., Avient Corporation, RTP Company, Polyplastics Co. Ltd., Lotte Chemical Corporation, Ensinger GmbH, Dawn Polymer Co. Ltd., Wanhua Chemical Group Co. Ltd., and China XD Plastics Co. Ltd., among others.

The main factors driving the modified plastics market include automotive lightweighting initiatives and electric vehicle expansion requiring high-performance lightweight materials, growing demand from electronics and 5G infrastructure development, metal replacement trends across multiple industries seeking cost-effective alternatives, increasing adoption of engineering plastics in consumer goods and appliances, rising construction activities in emerging economies, and sustainability initiatives driving demand for recycled and bio-based modified plastics.

Asia-Pacific region will lead the global modified plastics market during the forecast period 2025 to 2035.

Published Date: Jan-2026

Published Date: Sep-2024

Published Date: May-2024

Published Date: Jan-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates