Resources

About Us

Injection Molding Market Size, Share, Forecast, & Trends Analysis by Material (Plastic, Metal), Technology, (Structural Foam Molding, Liquid Silicone Injection Molding), Application, Sector (Packaging, Electronics, and Healthcare), and Geography - Global Forecast to 2032

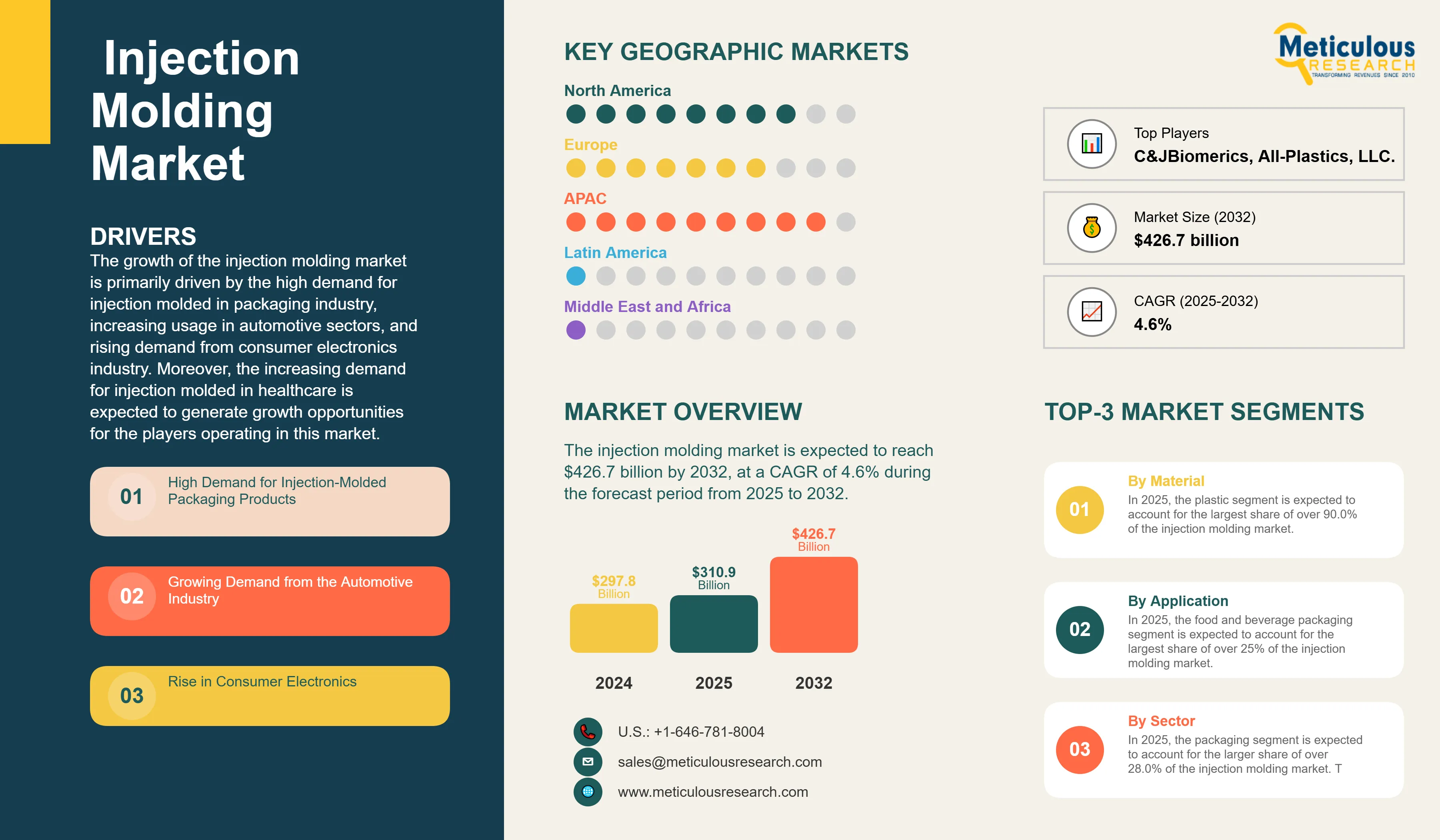

Report ID: MRCHM - 1041298 Pages: 310 Aug-2025 Formats*: PDF Category: Chemicals and Materials Delivery: 2 to 4 Hours Download Free Sample ReportThe injection molding market was valued at $297.8 billion in 2024. This market is expected to reach $426.7 billion by 2032 from an estimated $310.9 billion in 2025, at a CAGR of 4.6% during the forecast period from 2025 to 2032.

The growth of the injection molding market is primarily driven by the high demand for injection molded in packaging industry, increasing usage in automotive sectors, and rising demand from consumer electronics industry. Moreover, the increasing demand for injection molded in healthcare is expected to generate growth opportunities for the players operating in this market.

Click here to: Get Free Sample Pages of this Report

High Demand for Injection Molded in Packaging Industry Driving Market Growth

Injection molding plays a crucial role in the packaging industry due to its ability to produce complex, customized, and cost-effective packaging solutions. Injection molding allows for the creation of highly customized packaging designs. Manufacturers can produce packaging with specific shapes, sizes, textures, and features tailored to the needs of different products. This flexibility is essential for brands looking to differentiate their products on store shelves. Injection molding supports high-volume manufacturing with consistent quality, making it suitable for mass production of packaging items such as bottles, caps, containers, and closures. Also, injection molding supports a wide range of materials, including various types of plastics (e.g., PET, HDPE, PP) and even biodegradable polymers. This versatility allows manufacturers to choose materials that offer specific properties such as durability, flexibility, clarity, or barrier protection, depending on the application.

Also, injection molding enables the incorporation of advanced features into packaging designs, such as tamper resistance, child-proofing mechanisms, easy-open features, and precise dispensing systems. These functionalities enhance product safety, convenience, and user experience. In addition, continuous advancements in injection molding technology, such as multi-cavity molds, hot runners, and real-time monitoring systems, drive innovation in packaging design and manufacturing. These innovations enable faster production cycles, improved design capabilities, and enhanced product performance.

Thus, injection molding is integral to the packaging industry for its ability to produce customized, efficient, and high-quality packaging solutions.

Injection Molding Market Growth Opportunities

Increasing demand for Injection Molded in Healthcare

Injection molding plays a crucial role in the healthcare industry due to its ability to manufacture a wide range of medical devices and components efficiently and with high precision. Injection molding is extensively used to produce components for medical devices such as syringes, IV components, catheters, and respiratory masks. These components often require complex geometry and stringent tolerances, which injection molding achieves consistently. Also, many disposable medical supplies, including tubing, connectors, and surgical instruments, are manufactured using injection molding.

In addition, injection molding is utilized in dental and orthodontic applications for producing items like aligners, trays, and prosthetic components. These applications benefit from the material flexibility and precise molding capabilities offered by injection molding. Thus, the injection molding allows for the production of customized medical devices and components tailored to specific patient needs. This capability supports innovation in healthcare by enabling the development of new, more effective devices.

Consequently, as technology advances and materials improve, injection molding continues to play a pivotal role in advancing healthcare innovation and improving patient care.

Injection Molding Market Analysis: Key Findings

By Material: The Plastic Segment to Dominate the Injection Molding Market in 2024

Based on material, the injection molding market is segmented into plastic, metal, and other materials. In 2025, the plastic segment is expected to account for the largest share of over 90.0% of the injection molding market. The segment’s large share is attributed to the rising shift towards lightweight and durable materials in automotive sector, growing focus on using recycled materials and developing biodegradable plastics, growing emphasis on sustainable practices, and increasing demand for consumer products such as packaging, household items, and toys. In addition, the benefits associated with plastic injection molding, such as high precision and consistency, efficiency in mass production, design flexibility, material versatility, and automation and efficiency, further support the growth of this segment. Moreover, this segment is expected to grow at a higher CAGR during the forecast period.

By Technology: The Structural Foam Molding is Segment to Dominate the Injection Molding Market in 2024

Based on technology, the injection molding market is segmented into the gas-assisted injection molding, thin-wall molding, liquid silicone injection molding, structural foam molding, and metal injection molding. In 2025, the gas-assisted injection molding segment is expected to account for the largest share of the injection molding market. The large share of this technology is mainly due to its ability to produce large, complex, and lightweight parts with superior structural integrity and reduced material consumption. This process involves injecting nitrogen gas into the molten plastic, creating hollow sections that minimize sink marks and warping while enhancing strength-to-weight ratios. Industries such as automotive, consumer goods, and furniture favor GAIM for manufacturing components like handles, panels, and housings that require durability without excess weight. The technology’s cost efficiency—achieved through lower material usage and shorter cycle times—further solidifies its dominance, particularly in high-volume production where precision and consistency are critical.

By Application: The Food and Beverage Packaging is Segment to Dominate the Injection Molding Market in 2024

Based on application, the injection molding market is segmented into the automotive components, food and beverage packaging, stock materials, toys and figurines, mechanical components, electronics hardware and housings, medical device components, and other applications. In 2025, the food and beverage packaging segment is expected to account for the largest share of over 25% of the injection molding market. The segment’s large share is attributed to the increasing consumer demand for convenient, safe, and attractive food packaging, rising demand of precise, tamper-evident, and secure packaging solution, growing use of containers, dairy juice & water packaging, beverage caps & closures, and specialty closures. Moreover, this segment is expected to grow at a higher CAGR during the forecast period.

By Sector: The Packaging is Segment to Dominate the Injection Molding Market in 2024

Based on sector, the injection molding market is segmented into consumables & electronics, automotive, building & constructions, transportation, healthcare, packaging, consumer goods, mechanical engineering, and other sectors. In 2025, the packaging segment is expected to account for the larger share of over 28.0% of the injection molding market. This segment's large market share is attributed to the growing demand for custom and aesthetically pleasing packaging, rising need of specific shapes, sizes, textures, and features tailored to the needs of different products, rising adoption of packaging items such as bottles, caps, containers, and closures. In addition, the benefits associated with packaging sector, such as high efficiency, cost-effectiveness, precision, design flexibility, high-quality, durable, and customizable packaging, further support the growth of this segment. Moreover, this segment is expected to grow at a higher CAGR during the forecast period.

However, the healthcare segment is witnessing rapid growth as medical advancements and increasing health awareness drive demand for precision-engineered, sterile, and disposable plastic components. Injection molding is indispensable in producing medical devices such as syringes, IV components, surgical instruments, and diagnostic equipment housings, where material purity, dimensional accuracy, and biocompatibility are paramount.

Geographic Analysis

Asia-Pacific to Dominate the Injection Molding Market

Based on geography, the injection molding market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2025, Asia-Pacific is expected to account for the largest share of the over 45% of the injection molding market. The presence of prominent injection molding players is expected to contribute to the high revenue share of this region. In addition, the rapid growth in automotive industry, high demand for injection molded in packaging industry, rising demand from consumer electronics industry, and growing emphasis on sustainability drive the demand for injection molding in the region.

Furthermore, the rapid industrialization and governments in the region investing in infrastructure and manufacturing capabilities, are predicted to fuel the injection molding market's expansion Moreover, Asia-Pacific is expected to witness the highest CAGR of 5.4% during the forecast period. Also, the rapid growth of this regional market is attributed to the growth in regional economies and the rapid infrastructure development, especially in Japan, South Korea, and India.

Injection Molding Market: Key Companies

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3–4 years. Some of the key players operating in the injection molding market are Proto Labs (U.S.), The Rodon Group (U.S.), EVCO Plastics (U.S.), HTI Plastics (U.S.), Tessy Plastics (U.S.), C&J Industries, Inc. (U.S.), Biomerics (U.S.), All-Plastics, LLC. (U.S.), Majors Plastics, Inc. (U.S.), Currier Plastics, Inc. (U.S.), H&K Müller GmbH & Co. KG (Germany), Hehnke GmbH & Co KG (Germany), TR PLAST GROUP (Europe), and D&M Plastics, LLC (U.S.).

Injection Molding Industry Overview: Latest Developments from Key Industry Players

|

Particulars |

Details |

|

Number of Pages |

310 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

4.6% |

|

Market Size (2025) |

$310.9 Billion |

|

Market Size (2032) |

$426.7 Billion |

|

Segments Covered |

By Material

By Technology

By Application

By Sector

|

|

Countries Covered |

North America (U.S. and Canada), Europe (Germany, U.K., France, Italy, Spain, Switzerland, Poland, and Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Singapore, South Korea, Australia & New Zealand, and Rest of Asia-Pacific), Latin America and the Middle East & Africa |

|

Key Companies Profiled |

C&J Industries, Inc. (U.S.), Biomerics (U.S.), All-Plastics, LLC. (U.S.), Majors Plastics Inc. (U.S.), HTI Plastics (U.S.), The Rodon Group (U.S.), EVCO Plastics (U.S.), Tessy Plastics Corporation (U.S.), SCHOTT AG (Germany), ENGEL AUSTRIA GmbH (Austria), Husky Technologies (Canada), and NISSEI PLASTIC INDUSTRIAL CO., LTD. (Japan). |

The injection molding market study focuses on market assessment and opportunity analysis based on the sales of injection molding products across various countries, regions, and market segments. The study includes a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3–4 years.

The injection molding market is projected to reach $426.7 billion by 2032, at a CAGR of 4.6% during the forecast period 2025–2032.

In 2025, the packaging segment is expected to account for the larger share of over 25.0% of the injection molding market. This segment's large market share is attributed to the growing demand for custom and aesthetically pleasing packaging, rising need of specific shapes, sizes, textures, and features tailored to the needs of different products, rising adoption of packaging items such as bottles, caps, containers, and closures.

The growth of the injection molding market is primarily driven by the high demand for injection molded in packaging industry, increasing usage in automotive sectors, and rising demand from consumer electronics industry. Moreover, the increasing demand for injections molded in healthcare is expected to generate growth opportunities for the players operating in this market.

The key players operating in the injection molding market are C&J Industries, Inc. (U.S.), Biomerics (U.S.), All-Plastics, LLC. (U.S.), Majors Plastics Inc. (U.S.), HTI Plastics (U.S.), The Rodon Group (U.S.), EVCO Plastics (U.S.), Tessy Plastics Corporation (U.S.), SCHOTT AG (Germany), ENGEL AUSTRIA GmbH (Austria), Husky Technologies (Canada), and NISSEI PLASTIC INDUSTRIAL CO., LTD. (Japan).

At present, Asia-Pacific dominates the injection molding market. Moreover, Japan, China, India, and South Korea are expected to witness strong growth in the demand for injection molding in the coming years.

Published Date: Oct-2025

Published Date: May-2024

Published Date: May-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates