What is the Industrial Compressors Market Size?

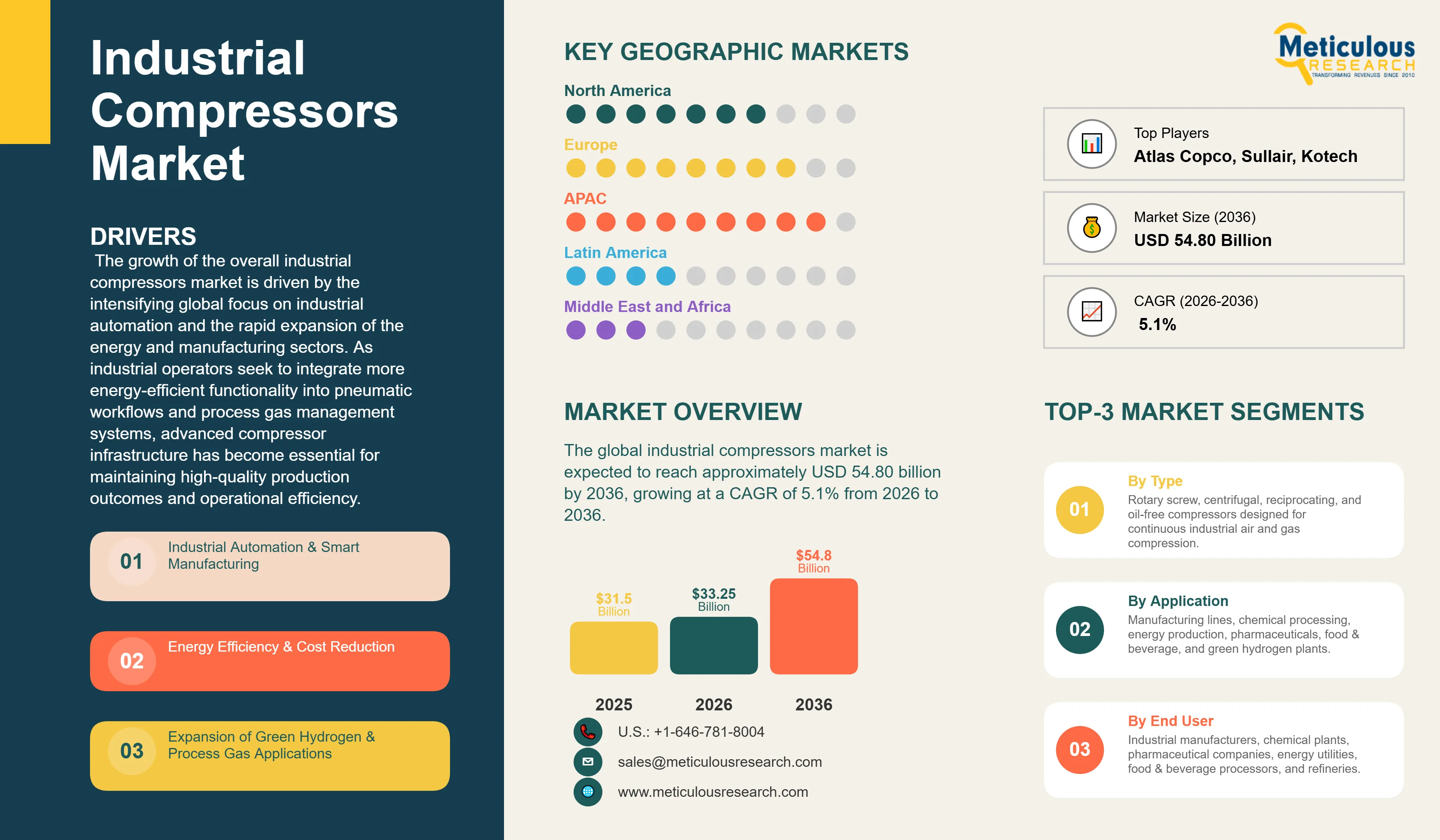

The global industrial compressors market was valued at USD 31.50 billion in 2025. The market is expected to reach approximately USD 54.80 billion by 2036 from USD 33.25 billion in 2026, growing at a CAGR of 5.1% from 2026 to 2036. The growth of the overall industrial compressors market is driven by the intensifying global focus on industrial automation and the rapid expansion of the energy and manufacturing sectors. As industrial operators seek to integrate more energy-efficient functionality into pneumatic workflows and process gas management systems, advanced compressor infrastructure has become essential for maintaining high-quality production outcomes and operational efficiency. The rapid expansion of green hydrogen infrastructure and the increasing need for high-purity oil-free air in the pharmaceutical and food sectors continue to fuel significant growth of this market across all major geographic regions.

Market Highlights: Global Industrial Compressors Market

- In terms of revenue, the global industrial compressors market is projected to reach USD 54.80 billion by 2036.

- The market is expected to grow at a CAGR of 5.1% from 2026 to 2036.

- Asia-Pacific dominates the global industrial compressors market with the largest market share in 2026, driven by massive industrialization and the presence of leading manufacturing hubs in China, India, and Vietnam.

- North America and Europe are expected to witness steady growth during the forecast period, supported by the replacement of aging infrastructure with energy-efficient smart compressors and the rapid adoption of sustainable manufacturing practices.

- By technology, the rotary segment holds the largest market share in 2026, particularly in supporting continuous industrial processes and high-demand manufacturing lines.

- By lubrication, the oil-flooded segment holds the largest market share in 2026, due to its rugged reliability and cost-effectiveness in heavy-duty industrial applications.

- By end-use industry, the manufacturing segment holds the largest share of the overall market in 2026.

Market Overview and Insights

Click here to: Get Free Sample Pages of this Report

Industrial compressors are critical engineering environments that leverage advanced compression technologies to provide optimized pneumatic processes and improved energy efficiency through a connected industrial infrastructure. These systems include integrated hardware, control software, and maintenance services designed to automate air delivery and enhance decision-making across the production continuum. The market is defined by high-efficiency technologies such as variable speed drives (VSD) and IoT-enabled predictive maintenance, which significantly enhance operational precision and resource utilization in high-pressure industrial environments. These systems are indispensable for facility administrators seeking to optimize their internal operations and meet aggressive energy savings and productivity targets.

The market includes a diverse range of solutions, ranging from small reciprocating units for basic workshop tools to massive centrifugal stages and high-pressure screw compressors. These systems are increasingly integrated with advanced components such as cloud-based monitoring platforms and 5G-enabled connectivity to provide services such as real-time air quality tracking and predictive maintenance of mechanical components. The ability to provide stable, high-precision compressed air while minimizing energy consumption has made industrial compressor technology the choice for enterprises where production accuracy and operational reliability are paramount.

The global industrial sector is pushing hard to modernize facility capabilities, aiming to meet carbon-neutral production targets and Industry 4.0 goals. This drive has increased the adoption of high-efficiency connectivity solutions, with advanced smart controllers helping to stabilize air pressure for ultra-high-precision manufacturing. At the same time, the rapid growth in the semiconductor and biotech markets is increasing the need for high-reliability, oil-free digital solutions.

What are the Key Trends in the Industrial Compressors Market?

Proliferation of VSD-Optimized Workflows and AI-Driven Control

Industrial operators across the industry are rapidly shifting to VSD-optimized workflows, moving well beyond traditional fixed-speed setups toward predictive and AI-driven control setups. Atlas Copco’s latest VSD+ compressor platforms deliver significantly higher energy savings, while Ingersoll Rand’s recent installations have slashed downtime in automotive assembly lines. The real game-changer comes with “smart” air systems featuring integrated natural language processing for diagnostics that maintains peak operational efficiency even in high-volume production environments. These advancements make high-precision compressed air support practical and cost-effective for everyone from regional manufacturing plants to global chemical complexes chasing excellence in energy efficiency and lower operational costs.

Innovation in Oil-Free Compression and Sustainable Power Solutions

Innovation in oil-free compression and sustainable power solutions is rapidly driving the industrial compressors market, as production procedures become more hygiene-sensitive and facility operations more eco-friendly. Equipment suppliers are now designing units that combine the durability of traditional stages with the purity of water-injected or dry-screw technology in a single platform, saving valuable filtration time and simplifying maintenance logistics. These systems often involve advanced heat recovery and integrated dryers capable of handling complex moisture requirements without compromising air quality or mechanical reliability.

At the same time, growing focus on sustainable manufacturing is pushing manufacturers to develop compressor solutions tailored to heat recovery and waste reduction principles. These systems help reduce environmental impact through smart energy recycling and the use of recyclable mechanical components. By combining high-density data connectivity with robust environmental performance, these new designs support both technological advancement and corporate sustainability, strengthening the resilience of the broader industrial value chain.

Market Summary Table

|

Parameter

|

Details

|

|

Market Size by 2036

|

USD 54.80 Billion

|

|

Market Size in 2026

|

USD 33.25 Billion

|

|

Market Size in 2025

|

USD 31.50 Billion

|

|

Market Growth Rate (2026-2036)

|

CAGR of 5.1%

|

|

Dominating Region

|

Asia-Pacific

|

|

Fastest Growing Region

|

Asia-Pacific

|

|

Base Year

|

2025

|

|

Forecast Period

|

2026 to 2036

|

|

Segments Covered

|

Product, Technology, Lubrication, Power Rating, End-use Industry, and Region

|

|

Regions Covered

|

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa

|

Market Dynamics

Drivers: Industrial Automation and the Rise of Energy-Efficient Manufacturing

A key driver of the industrial compressors market is the rapid movement of the global manufacturing industry toward automated, energy-efficient production models. Global demand for seamless pneumatic power, real-time pressure monitoring, and data-driven maintenance has created significant incentives for the adoption of smart compressor infrastructure. The trend toward “smart factories” and the integration of industrial devices into unified digital platforms drive operators toward scalable solutions that industrial compressors can uniquely provide. It is estimated that as factory adoption of IoT-enabled sensors rises and diagnostic tools become more decentralized through 2036, the need for robust, connected infrastructure increases significantly; therefore, AI-driven software and high-efficiency controllers, with their ability to ensure high-density power processing, are considered a crucial enabler of modern industrial delivery strategies.

Opportunity: Green Hydrogen Expansion and Integration of IoT Services

The rapid growth of the green hydrogen market and IoT-enabled service technologies provides great opportunities for the industrial compressors market. Indeed, the global surge in hydrogen deployment has created a compelling demand for systems that can handle massive gas throughput and provide ultra-high pressure for storage. These applications require high reliability, data security, and the ability to handle corrosive gases, all attributes that are met with advanced industrial compressor solutions. The remote monitoring service market is set to expand significantly through 2036, with industrial compressors poised for an expanding share as operators seek to maximize energy precision and minimize downtime. Furthermore, the increasing demand for AI-driven diagnostics and smart maintenance automation is stimulating demand for modular digital solutions that provide high-speed data transmission and operational flexibility.

Technology Insights

Why Does the Rotary Segment Lead the Market?

The rotary segment accounts for a significant portion of the overall industrial compressors market in 2026. This is mainly attributed to the versatile use of this technology in supporting continuous manufacturing, automated assembly lines, and complex pneumatic systems within modern industrial environments. These systems offer the most comprehensive way to ensure stable air delivery across diverse industrial applications. The manufacturing and automotive sectors alone consume a large share of rotary compressors, with major projects in China and Germany demonstrating the technology’s capability to handle high-density power requirements. However, the centrifugal segment is expected to grow at a rapid CAGR during the forecast period, driven by the growing need for massive air volumes, high-purity oil-free requirements, and technical support in complex chemical and power plant digital transformations.

End-use Industry Insights

How Does the Manufacturing Segment Dominate?

Based on end-use industry, the manufacturing segment holds the largest share of the overall market in 2026. This is primarily due to the massive volume of connected pneumatic tools and the rigorous production standards required for high-volume assembly. Current large-scale industrial zones are increasingly specifying high-density digital platforms to ensure compliance with global manufacturing standards and operator expectations for efficient production services.

The healthcare and food & beverages segment is expected to witness the fastest growth during the forecast period. The shift toward AI-enhanced hygiene control and the complexity of multi-modal production suites are pushing the requirement for advanced oil-free systems that can handle varied purity standards and high-resolution air quality monitoring while ensuring absolute reliability for safety-critical industrial decisions.

Lubrication Insights

Why Does Oil-flooded Technology Lead the Market?

The oil-flooded segment commands the largest share of the global industrial compressors market in 2026. This dominance stems from its superior ability to provide rugged, high-torque compression for heavy-duty industrial tasks, making it the technology of choice for high-performance industrial plants. Large-scale operations in construction, mining, and general manufacturing drive demand, with advanced units from providers like Ingersoll Rand and Sullair enabling reliable performance in complex industrial environments.

However, the oil-free segment is poised for steady growth through 2036, fueled by expanding applications in pharmaceutical and semiconductor manufacturing. Manufacturers face mounting pressure to optimize costs for high-purity, hygiene-sensitive applications, where oil-free technology provides a reliable alternative for safety-critical facility connectivity.

Regional Insights

How is Asia-Pacific Maintaining Dominance in the Global Industrial Compressors Market?

Asia-Pacific holds the largest share of the global industrial compressors market in 2026. The largest share of this region is primarily attributed to the massive industrial infrastructure and the presence of the world’s leading manufacturing hubs, particularly in China. China alone accounts for a significant portion of global industrial investment, with its position as a leading producer of automobiles and electronics driving sustained growth. The presence of leading manufacturers like Atlas Copco (regional plants) and a well-developed industrial supply chain provides a robust market for both standard and high-density compressor solutions.

Which Factors Support North America and Europe Market Growth?

North America and Europe together account for a substantial share of the global industrial compressors market. The growth of these markets is mainly driven by the need for technological modernization in the aerospace and pharmaceutical sectors. The demand for advanced smart systems in North America is mainly due to its large-scale energy infrastructure projects and the presence of innovators in the U.S.

In Europe, the leadership in precision engineering and the push for energy efficiency innovation are driving the adoption of high-reliability smart solutions. Countries like Germany, France, and the UK are at the forefront, with significant focus on integrating smart digital solutions into industrial workflows and advanced production systems to ensure the highest levels of performance and reliability.

Key Players

The companies such as Atlas Copco AB, Ingersoll Rand Inc., Kaeser Kompressoren SE, and Sullair, LLC (Hitachi Group) lead the global industrial compressors market with a comprehensive range of digital and VSD-driven solutions, particularly for large-scale industrial applications and high-speed production. Meanwhile, players including Gardner Denver (Ingersoll Rand), BOGE KOMPRESSOREN Otto Boge GmbH & Co. KG, ELGi Equipments Limited, and Quincy Compressor focus on specialized rotary screw technology, air treatment, and localized service platforms targeting the manufacturing and workshop sectors. Emerging manufacturers and integrated players such as Kotech Group, Quzhou Zhongdu Machinery Technology Co., Ltd., and Fusheng Co., Ltd. are strengthening the market through innovations in portable units and modular digital platforms.

Key Questions Answered