Resources

About Us

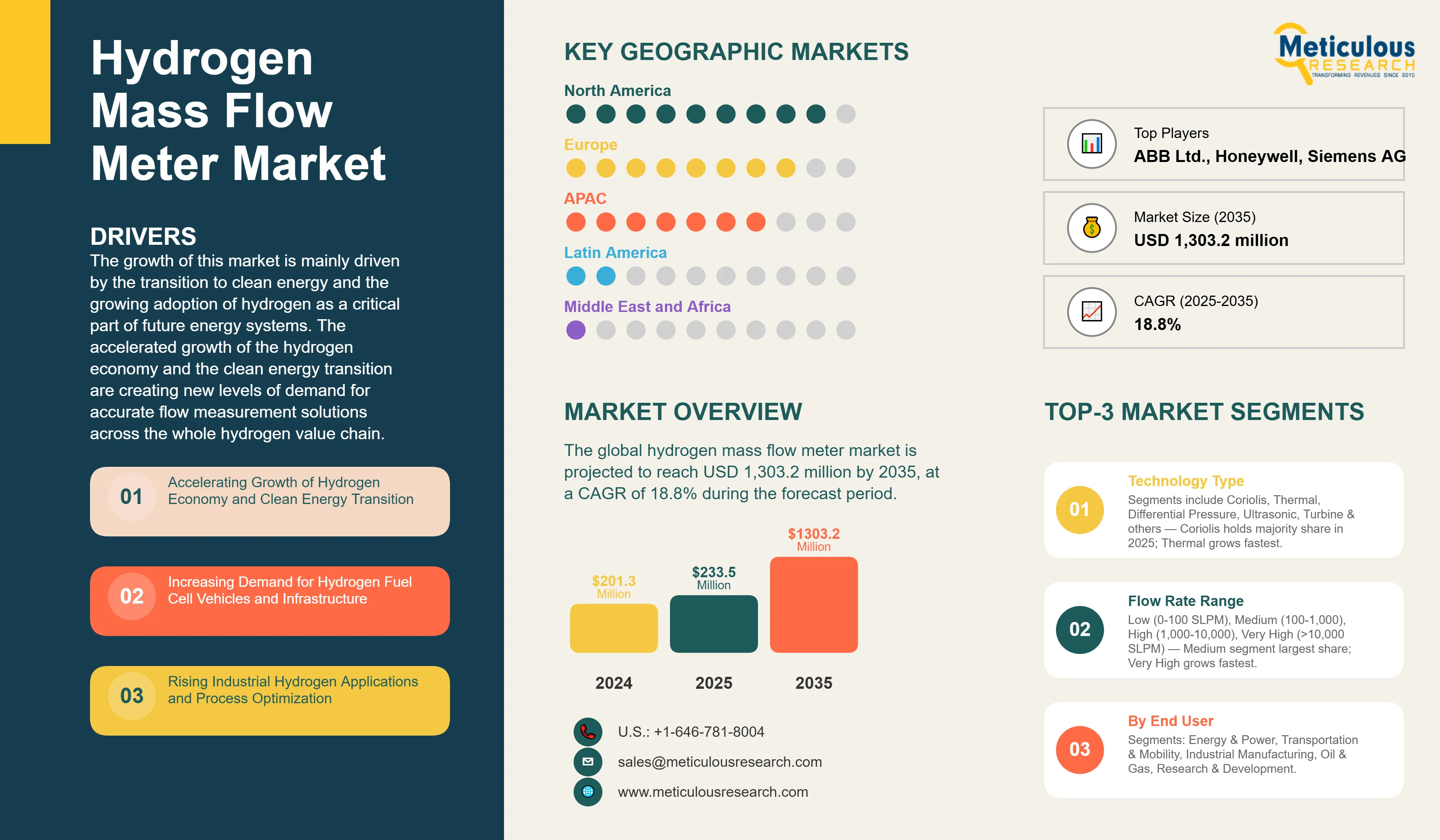

Hydrogen Mass Flow Meter Market Size, Share, Forecast, & Trends Analysis by Technology (Coriolis, Thermal, Differential Pressure, Ultrasonic) Flow Rate (Low, Medium, High) Pressure Rating (Low, Medium, High, Ultra-High) End-Use (Energy, Transportation, Industrial, Oil & Gas) - Global Forecast to 2035

Report ID: MREP - 1041538 Pages: 246 Sep-2025 Formats*: PDF Category: Energy and Power Delivery: 2 to 4 Hours Download Free Sample ReportThe global hydrogen mass flow meter market is projected to reach USD 1,303.2 million by 2035 from USD 233.5 million in 2025, at a CAGR of 18.8% during the forecast period. The market was valued at USD 201.3 million in 2024.

The growth of this market is mainly driven by the transition to clean energy and the growing adoption of hydrogen as a critical part of future energy systems. The accelerated growth of the hydrogen economy and the clean energy transition are creating new levels of demand for accurate flow measurement solutions across the whole hydrogen value chain. Organizations around the world are beginning to characterize accurate hydrogen flow measurement as critical to optimizing processes, achieving safety compliance, and enabling the economy of hydrogen operations. Hydrogen is highly flammable and diffusive; accurate measurement helps maintain safe pressure, detect leaks early, and meet global standards (e.g., ISO 14687, ATEX).

The growing interest in hydrogen fuel cell vehicles and infrastructure is also transforming the transportation sector across the globe. Large automotive manufacturers are investing in hydrogen fuel cell vehicles, while governments are also investing in hydrogen refueling station networks. In July 2025, Toyota announced investing $139 million through a joint venture with Shudao Investment Group to build a hydrogen fuel cell manufacturing base in Chengdu, China. Also, in 2023, Toyota introduced a hydrogen fuel cell version of its Hilux pickup. This prototype uses core components from the Mirai, such as its fuel cell and hydrogen tanks, and achieves a range of nearly 400 miles. The Hilux prototype is currently undergoing testing, with small-scale production anticipated in the coming years. This evolution will require sophisticated flow measurement systems to address the critical aspects of accurately measuring high-pressure, high-volume hydrogen gas in an extremely safe and reliable manner, either in vehicles or refueling stations.

The growth in industrial hydrogen applications and process optimization activities will allow the market to diversify across traditional applications. Industrials like steel making, chemical processing, and electronics manufacturing are deploying hydrogen-based processes that require advanced flow measurement technology. As hydrogen becomes increasingly integrated into industrial processes, flow meters will be required to consistently deliver high-precision measurements while operating reliably in harsh and demanding environments.

Nevertheless, the market faces significant challenges that must be addressed. High upfront capital and installation costs often place hydrogen projects beyond the reach of smaller stakeholders. Additionally, the cost of specialized hydrogen flow measurement technologies remains premium, particularly in high-pressure and high-accuracy applications.

The technical challenge of having consistent hydrogen measurement accuracy over varied operating conditions continues to pose elusive problems for both manufacturers and end users. The low density of hydrogen and its unique flow characteristics demand advanced sensor technology and new signal processing techniques that add complexity and cost to the measurement system.

The insufficient supply of trained technicians and maintenance capacity for hydrogen flow measurement systems creates operational challenges for end users. The specialized knowledge to calibrate, maintain, and troubleshoot hydrogen-specific flow meters is still evolving within an evolving industry.

Market Drivers and Insights

Click here to: Get Free Sample Pages of this Report

Accelerating Growth of Hydrogen Economy and Clean Energy Transition

Globally, the hydrogen economy is gaining incredible momentum as countries commit to reaching net-zero emissions and transitioning to cleaner fuels as an alternative to fossil fuels. According to the International Energy Agency’s Global Hydrogen Review 2024, global hydrogen demand is projected to reach 500 million tonnes by 2050—representing a fivefold increase compared to current levels. Such growth will require sophisticated flow measurement systems to track and measure hydrogen as it moves through its lifecycle from production to end-use.

Governments are catalyzing change by significantly investing in hydrogen development. For instance, the EU’s REPowerEU initiative earmarked up to €300 billion through 2027 to accelerate hydrogen deployment and energy diversification. The U.S. is providing federal tax incentives for the development of clean hydrogen through the Inflation Reduction Act, with hydrogen producers eligible for federal production tax credits of up to USD 3/kg under Section 45V. Japan has pledged around USD 107 billion (¥15 trillion) in public–private investment over 15 years to build a comprehensive hydrogen supply chain. South Korea is executing its Hydrogen Economy Roadmap with multi‑billion‑dollar commitments toward industrial hydrogen infrastructure, fuel cell development, and regional hydrogen hubs.

The hydrogen industry is evolving from small pilot projects to large-scale commercial hydrogen businesses. For early infrastructure and system installations, basic measurement devices were sufficient; as hydrogen technology advances with commercial production and distribution, the industry must rely on certified, high-precision flow meters designed to measure large volume and pressure reliably. As the industry is migrating away from pilot projects to commercial distribution, there will be many opportunities to replace and upgrade flow meter technology across the hydrogen sector.

Increasing Demand for Hydrogen Fuel Cell Vehicles and Infrastructure

The automotive industry is increasingly shifting toward hydrogen fuel cell vehicles, driving demand for specialized flow measurement technologies. Leading manufacturers such as Toyota, Hyundai, BMW, and Mercedes-Benz are scaling up hydrogen vehicle production, while commercial vehicle makers are similarly advancing hydrogen-powered trucks, buses, and industrial equipment.

China, South Korea, and Japan are the leading countries, collectively operating over 850 hydrogen stations. China alone has more than 540 stations, with plans to expand to over 1,000 stations by 2030. Each station is a valuable hub that relies on several high-accuracy flow meters to track how much hydrogen is stored, delivered, and dispensed safely and accurately. As of the end of 2024, there were over 1,100 hydrogen refueling stations (HRS) operational worldwide, marking a significant milestone in the global hydrogen infrastructure development. This represents a 60% increase from 2021, indicating accelerating adoption of hydrogen as a clean fuel alternative (Source: Hydrogen Council). Importantly, every new station represents a significant business opportunity for flow meter suppliers.

Hydrogen adoption in heavy-duty applications, including trucks and buses, is accelerating, with refueling flow rates often exceeding 10,000 standard liters per minute (SLPM). This rise in fuel delivery demands advanced industrial flow meters capable of precise, high-volume measurements under elevated pressures, with stringent safety standards. Key sectors such as logistics companies, ports, and mining operations are actively investing in hydrogen vehicle fleets and the associated measurement infrastructure essential for reliable and efficient operations.

Table: Key Factors Impacting Global Hydrogen Mass Flow Meter Market (2025–2035)

Base CAGR: 18.8%

|

Category |

Key Factor |

Short-Term Impact (2025–2028) |

Long-Term Impact (2029–2035) |

Estimated CAGR Impact |

|

Drivers |

||||

|

1. |

Accelerating Growth of Hydrogen Economy and Clean Energy Transition |

Major infrastructure projects begin |

Commercial-scale hydrogen economy established |

▲ +2.1% |

|

2. |

Increasing Demand for Hydrogen Fuel Cell Vehicles and Infrastructure |

Refueling network expansion |

Mass adoption of hydrogen vehicles |

▲ +1.8% |

|

3. |

Rising Industrial Hydrogen Applications and Process Optimization |

Pilot projects and early adoption |

Widespread industrial implementation |

▲ +1.5% |

|

Restraints |

||||

|

1. |

High Initial Investment and Installation Costs |

Limits adoption in smaller projects |

Economies of scale reduce impact |

▼ −1.0% |

|

2. |

Technical Challenges in Hydrogen Measurement Accuracy |

Performance limitations affect adoption |

Advanced technology resolves issues |

▼ −0.8% |

|

Opportunities |

||||

|

1. |

Development of Green Hydrogen Production Networks |

Large-scale production facilities |

Global green hydrogen infrastructure |

▲ +2.3% |

|

2. |

Integration of IoT and Smart Monitoring Technologies |

Early smart meter deployments |

Standard industry practice |

▲ +1.6% |

|

Trends |

||||

|

1. |

Advancement in Coriolis and Thermal Technologies |

Premium product differentiation |

Standard technology across segments |

▲ +0.9% |

|

Challenges |

||||

|

1. |

Long-Term Reliability in High-Pressure Environments |

Conservative adoption in critical apps |

Proven reliability enables growth |

▼ −0.3% |

Market Segmentation Analysis

By Technology Type

The hydrogen mass flow meter market is classified by technology type into Coriolis mass flow meters, thermal mass flow meters, differential pressure flow meters, ultrasonic flow meters, turbine flow meters, and others. The Coriolis mass flow meters segment is expected to hold the largest share of the overall hydrogen mass flow meter market in 2025, with around 45-50% of the total hydrogen mass flow meter market.

However, the thermal mass flow meters segment is expected to grow at the highest CAGR during the forecast period. This growth is primarily driven by the economic feasibility of thermal flow meters in high-volume applications, their superior performance across wide flow ranges, and lower pressure drop compared to alternative technologies. Additionally, thermal meters are increasingly favored in hydrogen production and storage sectors, where achieving high accuracy at minimal cost is critical.

By Flow Rate Range

The hydrogen mass flow meter market is segmented by flow rate into four categories, which include low flow rate (0-100 SLPM), medium flow rate (100-1,000 SLPM), high flow rate (1,000-10,000 SLPM), and very high flow rate (greater than 10,000 SLPM). The medium flow rate segment is expected to hold the largest share of the market in 2025, with approximately 35-40% market share. Electrolyzers and reformers in the 100–1,000 SLPM range are common in distributed hydrogen generation, fueling smaller refueling stations or industrial processes. Medium flow rates are typical for injecting hydrogen into natural gas pipelines or blending with other gases, requiring precise flow control. The growth of small to mid-scale hydrogen production, increasing hydrogen blending in natural gas pipelines, fuel cell testing activities, and the rise of compact refueling stations for light-duty vehicles and equipment are some of the major drivers for the growth of this segment.

The very high flow rate segment is expected to grow at the highest CAGR during the forecast period. The need for very high flow rate hydrogen measurement, exceeding 10,000 SLPM, is driven by large-scale industrial hydrogen production, heavy-duty vehicle refueling such as trucks and buses, and extensive hydrogen storage and distribution systems requiring rapid, accurate, and safe fuel delivery.

By Pressure Rating

Based on pressure rating, the hydrogen mass flow meter market is categorized as low pressure (up to 50 bar), medium pressure (50 - 200 bar), high pressure (200 - 700 bar), and ultra-high pressure (above 700 bar). The low-pressure segment is projected to hold the largest share in 2025, at approximately 30-40% of market share. The low-pressure segment (up to 50 bar) currently dominates because it covers a wide range of established hydrogen applications in production, research, and industrial settings where hydrogen is stored, transported, or consumed at relatively lower pressures. Electrolyzers, laboratory testing, semiconductor manufacturing, and many chemical and industrial processes operate within low-pressure environments, making this category the most commonly used today. Flow meters designed for low pressure are also more cost-effective, easier to integrate with existing systems, and sufficient for most pilot-scale hydrogen projects and small-scale distribution networks, which account for a large share of ongoing hydrogen activities.

However, the high-pressure segment (200–700 bar) is witnessing the fastest growth, driven primarily by the expansion of hydrogen mobility and refueling infrastructure. Fuel cell electric vehicles (FCEVs), buses, and heavy-duty trucks require hydrogen to be compressed and dispensed at high pressures (typically 350–700 bar) to achieve sufficient driving range and efficiency. As governments and companies scale up refueling networks and invest in hydrogen-based transportation, demand for mass flow meters capable of withstanding and accurately measuring at high pressures is rising sharply.

By End-Use Industry

The hydrogen mass flow meter market is segmented based on end-use industry: hydrogen production, hydrogen storage, energy & power generation, transportation & mobility, industrial manufacturing, oil & gas, and research & development. In 2025, the hydrogen production segment is expected to account for the largest share of the hydrogen mass flow meter market. The large share of this segment is attributed to the fact that accurate flow measurement is critical across all production pathways, whether through steam methane reforming (SMR), coal gasification, or increasingly, electrolysis. Producers must precisely monitor hydrogen output to ensure efficiency, safety, and compliance with purity and quality standards. Electrolyzer-based green hydrogen projects, in particular, rely heavily on mass flow meters for real-time monitoring of both hydrogen and oxygen flows, as well as for optimizing energy input versus hydrogen output. Since production is the foundation of the hydrogen value chain, spanning industrial-scale plants, pilot projects, and demonstration units worldwide, it naturally represents the largest share of demand for hydrogen mass flow meters today.

However, the transportation and mobility segment is witnessing the fastest growth as global hydrogen adoption shifts toward mobility applications such as fuel cell electric vehicles (FCEVs), buses, trucks, trains, and even marine and aviation trials. These applications require hydrogen to be dispensed and metered at high accuracy and under demanding pressure and flow conditions, making advanced mass flow meters indispensable in refueling stations and onboard systems.

Regional Analysis

On the basis of geography, the global hydrogen mass flow meter market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2025, North America is expected to command a share of 33% of the global hydrogen mass flow meter market. North America’s dominance stems from its early investments in hydrogen production and infrastructure, supported by substantial government funding and incentives such as the U.S. Inflation Reduction Act. The region also has a highly developed industrial base with strong adoption of hydrogen across refining, chemicals, and power applications. In addition, North American companies are leaders in fuel cell electric vehicles (particularly for heavy-duty trucks and buses), where mass flow meters play a critical role in precise hydrogen dispensing and monitoring. The presence of established players, advanced R&D capabilities, and a robust pipeline of large-scale green hydrogen projects further strengthens its position as the largest market.

However, Asia-Pacific is witnessing the fastest growth, at a CAGR of 26%, due to rapid scaling of clean hydrogen initiatives in countries such as China, Japan, South Korea, India, and Australia. These countries are aggressively pursuing hydrogen strategies to decarbonize transportation, industrial manufacturing, and power sectors, with governments setting ambitious hydrogen adoption targets. Japan and South Korea are frontrunners in hydrogen mobility, driving demand for mass flow meters in fueling stations and vehicle integration. China is investing heavily in green hydrogen production linked to renewable energy, while India and Australia are positioning themselves as global hydrogen exporters. This accelerated pace of infrastructure build-out, coupled with government-backed roadmaps and significant private sector participation, positions Asia-Pacific as the fastest-growing region in the hydrogen mass flow meter market.

Key Players in the Global Hydrogen Mass Flow Meter Market

Some of the major players that operate in the global hydrogen mass flow meter market include Emerson Electric Co. (Micro Motion) (U.S.), Endress+Hauser Group (Switzerland), ABB Ltd. (Switzerland), Yokogawa Electric Corporation (Japan), Honeywell International Inc. (U.S.), Siemens AG (Germany), Krohne Group (Germany), Bronkhorst High-Tech B.V. (Netherlands), Brooks Instrument (ITW) (U.S.), RHEONIK Messtechnik GmbH (Germany), Sierra Instruments Inc. (U.S.), Alicat Scientific Inc. (U.S.), TSI Incorporated (U.S.), Sensirion AG (Switzerland), Teledyne Hastings Instruments, (U.S.), KOBOLD Group (Germany), and Fox Thermal Instruments, Inc.(U.S.)

Each company is undergoing diverse actions to capitalize on its position in the market. Industrial automation leaders Emerson and Endress+Hauser are leveraging the advantages of their global service platforms and pre-existing customer relationships, while specialized flow meter manufacturers such as Bronkhorst and Alicat are developing more accurate, hydrogen-optimized products for research and precision.

|

Particulars |

Details |

|

Number of Pages |

246 |

|

Forecast Period |

2025–2035 |

|

Base Year |

2024 |

|

CAGR (Value) |

18.8% |

|

Market Size 2024 |

USD 201.3 million |

|

Market Size 2025 |

USD 233.5 million |

|

Market Size 2035 |

USD 1,303.2 billion |

|

Segments Covered |

By Technology Type, Flow Rate Range, Pressure Rating, and End-Use Industry |

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Netherlands, Norway, Rest of Europe), Asia-Pacific (Japan, South Korea, China, India, Australia, Rest of Asia-Pacific), Latin America (Brazil, Chile, Mexico, Rest of Latin America), and the Middle East & Africa (Saudi Arabia, UAE, South Africa, Rest of Middle East & Africa) |

The hydrogen mass flow meter market is projected to reach USD 1,303.2 billion by 2035 from USD 180 million in 2025, at a CAGR of 18.8% during the forecast period.

In 2025, the Coriolis mass flow meters segment is projected to hold the major share of the hydrogen mass flow meter market, while the thermal mass flow meters segment is slated to record the highest growth rate due to cost-effectiveness and performance advantages in large-volume applications.

Key factors driving growth include the accelerating growth of the hydrogen economy and clean energy transition, increasing demand for hydrogen fuel cell vehicles and infrastructure, rising industrial hydrogen applications and process optimization, stringent safety and regulatory standards for hydrogen handling, and government initiatives and investment in hydrogen technologies.

North America leads the market with the highest share due to aggressive government policies and infrastructure investments, while Asia-Pacific is projected to record the highest growth rate during the forecast period, offering significant opportunities for hydrogen mass flow meter vendors.

Major opportunities include the development of green hydrogen production and distribution networks, integration of IoT and smart monitoring technologies, expansion of hydrogen storage and transportation infrastructure, emerging applications in power-to-gas and energy storage systems, and growth in hydrogen blending for natural gas networks.

Key trends include advancement in Coriolis and thermal mass flow measurement technologies, development of explosion-proof and intrinsically safe designs, integration of digital communication protocols and data analytics, and miniaturization for portable and mobile hydrogen applications.

The transportation and mobility segment is witnessing the fastest growth as global hydrogen adoption shifts toward mobility applications such as fuel cell electric vehicles (FCEVs), buses, trucks, trains, and even marine and aviation trials. These applications require hydrogen to be dispensed and metered at high accuracy and under demanding pressure and flow conditions, making advanced mass flow meters indispensable in refueling stations and onboard systems.

Published Date: Oct-2025

Published Date: Oct-2025

Published Date: Jan-2026

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates