Resources

About Us

Manufacturing Execution Systems Market by Offering (Software, Services), Deployment Mode, Process Industry, Discrete Industry and Geography—Global Forecast to 2032

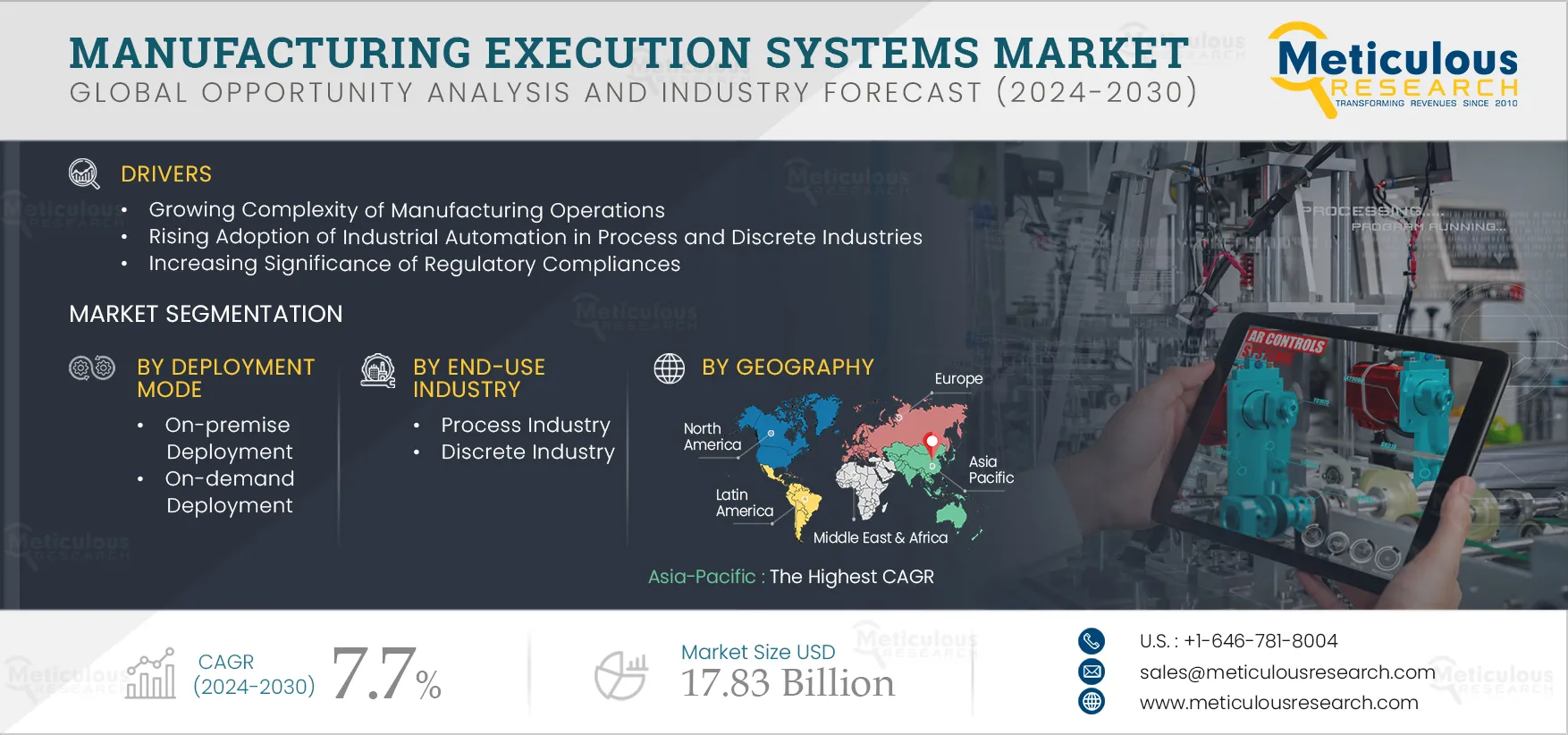

Report ID: MRICT - 104762 Pages: 300 Jan-2025 Formats*: PDF Category: Information and Communications Technology Delivery: 24 to 72 Hours Download Free Sample ReportThe Manufacturing Execution Systems Market is projected to reach $ 17.83 billion by 2032, at a CAGR of 7.7% from 2025 to 2032. The growth of this market is attributed to the growing complexity of manufacturing operations, the rising adoption of industrial automation in process and discrete industries and the increasing significance of regulatory compliances. Furthermore, the integration of MES with solutions such as ERP and PLM and increasing applications of MES in the pharmaceutical industry are expected to create significant opportunities for the players operating in this market.

However, the complexities in deploying MES in various industries pose challenges to the growth of this market. Additionally, the requirement of significant capital investments and upgradation & maintenance costs are restraining market growth.

The pandemic severely impacted several sectors, with major manufacturers shutting down their operations completely or operating at reduced capacities following the directives issued by their respective governments. Uncertainty regarding the duration of the lockdown and supply-chain disruptions made it more difficult for players to anticipate the recovery. This crisis caused structural shifts that had significant implications for the market.

The COVID-19 outbreak had a negative impact on the growth of the manufacturing execution systems market. Major halts in many industrial operations, such as manufacturing plants not operating and low productivity in manufacturing units, impacted several important players operating in this market. The pandemic also caused several manufacturing facilities to close. Several end industry operations, including those in the power generation, oil and gas, and automotive sectors, saw significant transformation during the post-pandemic phase. The manufacturing execution systems market is expected to expand in the coming years owing to the various operations & guidelines that have been established for COVID-19 for smoother operations.

The global manufacturing execution systems market is segmented by offering, deployment mode, end-use industry, and geography. The study also evaluates industry competitors and analyses the regional and country-level markets.

Click here to: Get Free Sample Copy of this report

With the continuously evolving trends in the pharmaceutical industry, manufacturers are experiencing increased pressure to keep pace and modify their operations to meet changing needs. Manufacturing execution systems (MES) enable the pharmaceutical industry to reduce production costs and improve compliance with regulatory requirements significantly.

The growing concern about counterfeit drugs entering the supply chain has resulted in the adoption of global track and trace regulations to protect patient safety and ensure product integrity, which is significantly contributing to the MES market growth. Furthermore, the regulations such as the Falsified Medicines Directive (FMD) by the European Union Parliament, the Drug Supply Chain Security Act (DSCSA, U.S.) by the U.S. Food and Drug Administration, and other similar global regulations are pushing manufacturers to ensure compliance, innovate technologies, and increase the resources to manage the additional administrative burden.

Moreover, by leveraging MES, the pharmaceutical industry efficiently manages the quality of traceability and tracking through barcodes and serialization numbers, as well as by incorporating RFID tags inside the packaging equipment while ensuring the safety of manufacturing processes.

Based on Offering, the Service Segment is Projected to Register the Highest CAGR During the Forecast Period

Based on offering, the global manufacturing execution systems market is segmented into software and services. The services segment is projected to register the highest CAGR during the forecast period. The key factor propelling the growth of this segment is the increasing significance of the global post-implementation procedure of several industrial execution systems. Other factors anticipated to drive the growth and demand for the services segment over the forecast period include improved efficiency, decreased waste, and shorter output times in the manufacturing process of various applications in industries, including food & beverages, pharmaceuticals, and consumer packaged goods

Based on Deployment, the Hybrid Deployment Segment is Projected to Register the Highest CAGR During the Forecast Period

Based on deployment mode, the global manufacturing execution systems market is segmented into on-premise deployment, on-demand deployment, and hybrid deployment. The hybrid deployment segment is projected to register the highest CAGR during the forecast period. The hybrid deployment type is widely preferred in oil & gas and energy & power sectors because of the increasing need for real-time information for monitoring activities in these sectors. A hybrid deployment also provides additional storage capacity, which ensures data protection.

Based on Application, the Quality Management Segment is Projected to Register the Highest CAGR During the Forecast Period

Based on application, the global manufacturing execution systems market is segmented into monitoring, production control, production documentation, production disposition, inventory management, maintenance, quality management, plant-wide production planning and other applications. The quality management segment is projected to register the highest CAGR during the forecast period. The growth of this segment is attributed to the increasing use of MES to control multiple elements of the production process to ensure high output quality. This application is mostly preferred in regulated industries like food & beverages or pharmaceuticals.

Based on End-use Industry, the Process Industry Segment is Projected to Register the Highest CAGR During the Forecast Period

Based on end-use industry, the global manufacturing execution systems market is segmented into process industry and discrete industry. The process industry segment is projected to register the highest CAGR during the forecast period. The growth of this segment is attributed to constantly shifting market dynamics and manufacturers’ rising need to adapt manufacturing processes to meet growing consumer needs.

Asia-Pacific is Slated to Register the Highest CAGR During the Forecast Period

Based on geography, the global manufacturing execution systems market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific is slated to register the highest CAGR during the forecast period. The growth of this region is driven by growing technological investments in the production of industrial tools and machinery, the growth and expansion of the semiconductor sector, and rising demand for MES from the chemical and automotive industries. Furthermore, the growing investments in R&D activities in China and India have further strengthened the Asia-Pacific MES market. Additionally, this market is expected to grow significantly over the next several years due to increasing industry knowledge of execution systems for manufacturing processes. Furthermore, China is investing significantly in using AI in the pharmaceutical industry, accelerating the market expansion rate. Another factor driving the growth of this market is the rise in manufacturing facilities across various industries, including those that depend heavily on manufacturing execution systems, such as the automotive, textile, power, and pharmaceutical industries.

Key Players

The key players profiled in the global manufacturing execution systems market study include Siemens AG (Germany), Rockwell Automation, Inc. (U.S.), SAP SE (Germany), ABB Ltd (Switzerland), Dassault Systèmes S.A. (France), AVEVA Group Plc (U.K.), Applied Materials Inc. (U.S.), Oracle Corporation (U.S.), General Electric Company (U.S.), Emerson Electric Co. (U.S.), Epicor Software Corporation (U.S.), Infor Equity Holdings LLC (U.S.), Eyelit Inc. (Canada), Aegis Industrial Software Corporation (U.S.) and Critical Manufacturing, S.A. (Portugal).

Scope of the Report:

Manufacturing Execution Systems Market, by Offering

Software

Manufacturing Execution Systems Market, by Deployment Mode

On-premise Deployment

Manufacturing Execution Systems Market, by Application

Monitoring

Manufacturing Execution Systems Market, by End-use Industry

Process Industry

Manufacturing Execution Systems Market, by Geography

Asia-Pacific

Key Questions Answered in the Report:

The Manufacturing Execution Systems Market is projected to reach $17.83 billion by 2032.

The market is expected to grow at a CAGR of 7.7% from 2025 to 2032.

The pandemic caused a significant slowdown in the market due to the halt in manufacturing operations, supply chain disruptions, and decreased productivity. However, recovery is expected as companies adjust operations in line with post-pandemic guidelines, contributing to future MES growth.

Opportunities are emerging from:

The services segment is projected to register the highest growth, driven by the importance of post-implementation procedures and improvements in efficiency and waste reduction.

The hybrid deployment mode is expected to witness the highest growth, particularly in industries like oil & gas and energy, where real-time data monitoring and data protection are crucial.

The quality management segment is anticipated to grow the fastest due to the increasing use of MES to ensure high production quality, especially in regulated industries like pharmaceuticals and food & beverages.

The process industry segment, including sectors such as food & beverages, pharmaceuticals, and energy, is projected to register the highest CAGR, driven by dynamic market conditions and the need for adaptable manufacturing processes.

Asia-Pacific is expected to register the highest CAGR, driven by technological investments, expanding industrial sectors (especially semiconductors and pharmaceuticals), and growing demand for MES in the region's automotive and chemical industries.

Published Date: Aug-2024

Published Date: Oct-2022

Published Date: May-2025

Published Date: Sep-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates