Resources

About Us

Industrial Waste Management Market by Waste Type (Non-hazardous, Hazardous), Service (Collection, Recycling, Treatment & Disposal), and Industry (Manufacturing, Energy, Construction, Chemical) – Global Forecast to 2036

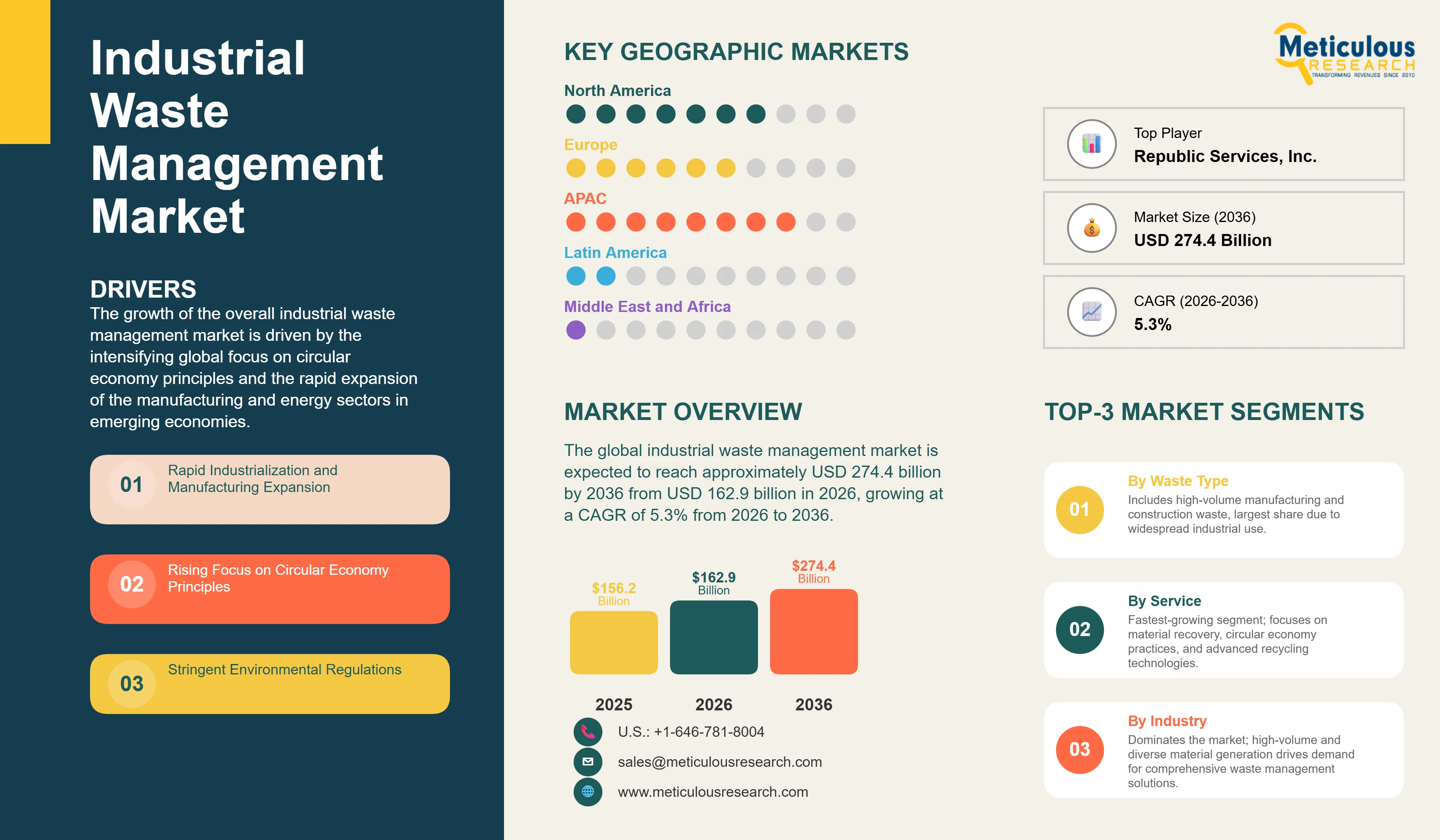

Report ID: MREP - 1041742 Pages: 278 Feb-2026 Formats*: PDF Category: Energy and Power Delivery: 24 to 72 Hours Download Free Sample ReportThe global industrial waste management market was valued at USD 156.2 billion in 2025. The market is expected to reach approximately USD 274.4 billion by 2036 from USD 162.9 billion in 2026, growing at a CAGR of 5.3% from 2026 to 2036. The growth of the overall industrial waste management market is driven by the intensifying global focus on circular economy principles and the rapid expansion of the manufacturing and energy sectors in emerging economies. As manufacturers seek to integrate more functionality into their resource recovery substrates and reduce the environmental footprint of their production cycles, advanced waste treatment and recycling systems have become essential for maintaining high-speed operational compliance and mechanical durability. The rapid expansion of the industrial infrastructure in Asia-Pacific and the increasing need for high-density hazardous waste solutions in chemical processing and advanced metallurgy continue to fuel significant growth of this market across all major geographic regions.

Click here to: Get Free Sample Pages of this Report

Click here to: Get Free Sample Pages of this Report

Industrial Waste Management refers to critical environmental service systems used to provide waste handling while allowing for resource recovery and space-saving designs throughout the industrial lifecycle. These systems include collection, recycling, treatment, and disposal processes, which are designed to withstand high-volume data processing and fit into non-linear industrial environments. The market is defined by high-efficiency technologies such as AI-driven sorting and plasma gasification, which significantly enhance material recovery and signal performance in high-frequency applications. These systems are indispensable for manufacturers seeking to optimize their internal resource architecture and meet aggressive sustainability targets.

The market includes a diverse range of configurations, ranging from simple collection routes for basic manufacturing waste to complex multilayer hazardous treatment systems for high-performance chemical and radioactive materials. These systems are increasingly integrated with advanced components such as IoT sensors and ultra-fast tracking engines to provide services such as real-time waste monitoring and improved heat recovery. The ability to provide stable, high-precision management while minimizing physical environmental footprint has made advanced industrial waste management the technology of choice for industries where operational efficiency and reliability are paramount.

The global industrial sector is pushing hard to modernize production capabilities, aiming to meet AI-driven monitoring and IoT connectivity targets. This drive has increased the adoption of high-density waste pipelines, with advanced “smart” recycling techniques helping to stabilize production yields for ultra-fine material features. At the same time, the rapid growth in the electric vehicle and green energy markets is increasing the need for high-reliability, specialized battery and chemical waste solutions.

Manufacturers across the waste industry are rapidly shifting to AI-optimized hardware, moving well beyond traditional manual sorting toward high-speed, low-loss digital setups. Waste Management’s latest high-capacity recycling centers deliver significantly higher data throughput for material recovery, while Veolia’s recent installations have slashed reagent interference in 5G-enabled hazardous waste plants. The real game-changer comes with “smart” waste management circuits featuring integrated sensors and shielding capabilities that maintain peak performance even in electromagnetically noisy environments. These advancements make high-precision resource management practical and cost-effective for everyone from industrial startups to global energy giants chasing operational excellence and lower system weight.

Innovation in circular economy and ultra-thin hybrid systems is rapidly driving the industrial waste market, as manufacturing facilities become more compact and multi-functional. Equipment suppliers are now designing units that combine the structural integrity of traditional disposal with the versatility of resource recovery in a single assembly, saving valuable internal space and simplifying assembly logistics. These systems often involve advanced laser monitoring and plasma etching capable of handling ultra-fine waste particles without compromising mechanical strength or electrical reliability.

At the same time, growing focus on sustainable manufacturing is pushing manufacturers to develop waste solutions tailored to circular economy principles. These systems help reduce material waste through additive manufacturing processes and the use of recyclable substrates. By combining high-density interconnectivity with robust environmental performance, these new designs support both technological advancement and corporate sustainability, strengthening the resilience of the broader industrial value chain.

|

Parameter |

Details |

|

Market Size by 2036 |

USD 274.4 Billion |

|

Market Size in 2026 |

USD 162.9 Billion |

|

Market Size in 2025 |

USD 156.2 Billion |

|

Market Growth Rate (2026-2036) |

CAGR of 5.3% |

|

Dominating Region |

Asia-Pacific |

|

Fastest Growing Region |

Asia-Pacific |

|

Base Year |

2025 |

|

Forecast Period |

2026 to 2036 |

|

Segments Covered |

Waste Type, Service, Industry, and Region |

|

Regions Covered |

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

A key driver of the industrial waste management market is the rapid movement of the global industrial sector toward cleaner, more portable, and highly functional production processes. Global demand for high-purity materials, carbon neutrality, and health-monitoring industrial zones has created significant incentives for the adoption of advanced waste systems. The trend toward “zero-waste” technology and the integration of environmental controls into smart factory patches drive manufacturers toward scalable solutions that industrial waste management can uniquely provide. It is estimated that as industrial adoption of IoT-enabled monitoring rises and environmental diagnostic tools become more decentralized through 2036, the need for robust, high-capacity management increases significantly; therefore, recycling and hazardous treatment systems, with their ability to ensure high-density packaging, are considered a crucial enabler of modern industrial design strategies.

The rapid growth of the green energy market and specialized waste technologies provides great opportunities for the industrial waste management market. Indeed, the global surge in battery production has created a compelling demand for systems that can replace heavy traditional disposal and integrate seamlessly into battery management systems (BMS). These applications require high reliability, thermal resistance, and the ability to handle high-vibration environments, all attributes that are met with advanced environmental circuits. The green industrial market is set to expand significantly through 2036, with industrial waste management poised for an expanding share as manufacturers seek to maximize operational range and minimize environmental weight. Furthermore, the increasing demand for hydrogen-ready sensors and waste-to-energy displays is stimulating demand for modular environmental solutions that provide high-speed data transmission and design flexibility.

The non-hazardous waste segment accounts for a significant portion of the overall industrial waste management market in 2026. This is mainly attributed to the versatile use of this technology in supporting high-volume manufacturing and construction activities within extremely tight spaces, such as in premium industrial parks and high-performance building modules. These systems offer the most comprehensive way to ensure material integrity across diverse high-frequency applications. The manufacturing and construction sectors alone consume a large share of non-hazardous waste production, with major projects in Asia Pacific and North America demonstrating the technology’s capability to handle high-density environmental requirements. However, the hazardous waste segment is expected to grow at a rapid CAGR during the forecast period, driven by the growing need for robust treatment in chemical plants, medical facilities, and aerospace systems.

Based on service, the collection and transportation segment holds the largest share of the overall market in 2026. This is primarily due to the massive volume of waste generation and the rigorous logistics standards required for modern industrial facilities. Current large-scale manufacturing plants are increasingly specifying high-density environmental circuits to ensure compliance with global performance standards and consumer expectations for cleaner, more reliable logistics.

The recycling and resource recovery segment is expected to witness the fastest growth during the forecast period. The shift toward vehicle electrification and the complexity of autonomous sensor suites are pushing the requirement for advanced environmental systems that can handle varied temperatures and mechanical stresses while ensuring absolute reliability for safety-critical industrial systems.

The manufacturing segment commands the largest share of the global industrial waste management market in 2026. This dominance stems from its superior volume of production, material diversity, and excellent mechanical properties, making it the primary target for high-performance environmental circuits. Large-scale operations in automotive, electronics, and high-end manufacturing drive demand, with advanced services from suppliers like Waste Management and Veolia enabling reliable performance in extreme environments.

However, the energy and utilities segment is poised for steady growth through 2036, fueled by expanding applications in low-cost transport goods and simple combustion switches. Manufacturers face mounting pressure to optimize costs for high-volume, less demanding applications, where specialized oil and gas waste services provide a cost-effective alternative for basic environmental connectivity.

Asia Pacific holds the largest share of the global industrial waste management market in 2026. The largest share of this region is primarily attributed to the massive industrialization and the presence of the world’s largest manufacturing hubs, particularly in China, India, and South Korea. China alone accounts for a significant portion of global environmental system production, with its position as a leading exporter of high-end industrial equipment driving sustained growth. The presence of leading manufacturers like Daiseki and a well-developed industrial supply chain provides a robust market for both standard and high-density environmental solutions.

North America and Europe together account for a substantial share of the global industrial waste management market. The growth of these markets is mainly driven by the need for technological modernization in the aerospace, defense, and medical sectors. The demand for advanced environmental systems in North America is mainly due to its large-scale defense projects and the presence of innovators like Waste Management and Republic Services.

In Europe, the leadership in environmental engineering and the push for circular economy innovation are driving the adoption of high-reliability environmental circuits. Countries like Germany, France, and the UK are at the forefront, with significant focus on integrating smart environmental solutions into industrial automation and advanced healthcare devices to ensure the highest levels of performance and reliability.

The companies such as Waste Management, Inc., Veolia Environnement S.A., Republic Services, Inc., and Clean Harbors, Inc. lead the global industrial waste management market with a comprehensive range of collection and treatment solutions, particularly for large-scale manufacturing and high-speed applications. Meanwhile, players including Suez S.A., Waste Connections, Inc., Stericycle, Inc., and Remondis SE & Co. KG focus on specialized hazardous and high-density circuits targeting the chemical, medical, and metallurgical sectors. Emerging manufacturers and integrated players such as Biffa plc, Covanta Holding Corporation, and Daiseki Co., Ltd. are strengthening the market through innovations in waste-to-energy technology and modular environmental platforms.

The global industrial waste management market is expected to grow from USD 162.9 billion in 2026 to USD 274.4 billion by 2036.

The global industrial waste management market is projected to grow at a CAGR of 5.3% from 2026 to 2036.

Non-hazardous waste is expected to dominate the market in 2026 due to its superior volume and broad application in manufacturing. However, Hazardous waste is projected to be the fastest-growing segment owing to its increasing generation in chemical, medical, and aerospace applications where specialized treatment is required.

AI and IoT are transforming the industrial waste landscape by demanding higher data integrity, lower latency, and improved thermal management. These technologies drive the adoption of advanced materials like smart sensors and AI-driven sorting engines, enabling manufacturers to support the complex routing and high-frequency requirements of next-generation industrial plants and green infrastructure.

Asia Pacific holds the largest share of the global industrial waste management market in 2026. The largest share of this region is primarily attributed to the massive industrialization and the presence of the world’s largest manufacturing hubs in China, India, and South Korea. North America and Europe together account for a substantial share, driven by high-end applications in aerospace, defense, and medical electronics.

The leading companies include Waste Management, Inc., Veolia Environnement S.A., Republic Services, Inc., Clean Harbors, Inc., and Suez S.A.

1. Introduction

1.1. Market Definition

1.2. Market Scope

1.3. Research Methodology

1.4. Assumptions & Limitations

2. Executive Summary

3. Market Overview

3.1. Introduction

3.2. Market Dynamics

3.2.1. Drivers

3.2.2. Restraints

3.2.3. Opportunities

3.2.4. Challenges

3.3. Impact of AI and IoT on the Industrial Waste Management Industry

3.4. Regulatory Landscape & Standards (RCRA, EU Waste Framework, China Zero Waste)

3.5. Porter’s Five Forces Analysis

4. Global Industrial Waste Management Market, by Waste Type

4.1. Introduction

4.2. Non-Hazardous Waste

4.2.1. Manufacturing Waste

4.2.2. Construction & Demolition Waste

4.2.3. Mining Waste

4.2.4. Oil & Gas Waste

4.3. Hazardous Waste

4.3.1. Chemical Waste

4.3.2. Medical Waste

4.3.3. Radioactive Waste

4.3.4. Flammable & Corrosive Waste

5. Global Industrial Waste Management Market, by Service

5.1. Introduction

5.2. Collection & Transportation

5.3. Recycling & Resource Recovery

5.4. Treatment & Disposal

5.4.1. Landfill

5.4.2. Incineration / Combustion

5.4.3. Open Dumping

5.5. On-site & Field Services

6. Global Industrial Waste Management Market, by Industry

6.1. Introduction

6.2. Manufacturing

6.2.1. Automotive

6.2.2. Electronics

6.2.3. Food & Beverage

6.3. Energy & Utilities

6.3.1. Oil & Gas

6.3.2. Power Generation

6.4. Construction & Demolition

6.5. Chemical & Pharmaceutical

6.6. Mining & Metallurgy

6.7. Others

7. Global Industrial Waste Management Market, by Region

7.1. Introduction

7.2. North America

7.2.1. U.S.

7.2.2. Canada

7.3. Europe

7.3.1. Germany

7.3.2. France

7.3.3. U.K.

7.3.4. Italy

7.3.5. Spain

7.3.6. Netherland

7.3.7. Rest of Europe

7.4. Asia-Pacific

7.4.1. China

7.4.2. Japan

7.4.3. South Korea

7.4.4. India

7.4.5. Australia

7.4.6. Rest of Asia-Pacific

7.5. Latin America

7.5.1. Brazil

7.5.2. Mexico

7.5.3. Rest of Latin America

7.6. Middle East & Africa

7.6.1. Saudi Arabia

7.6.2. UAE

7.6.3. South Africa

7.6.4. Rest of Middle East and Africa

8. Competitive Landscape

8.1. Overview

8.2. Key Growth Strategies

8.3. Competitive Benchmarking

8.4. Competitive Dashboard

8.4.1. Industry Leaders

8.4.2. Market Differentiators

8.4.3. Vanguards

8.4.4. Emerging Companies

8.5. Market Ranking/Positioning Analysis of Key Players, 2024

9. Company Profiles (Manufacturers & Providers)

9.1. Waste Management, Inc. (WM)

9.2. Veolia Environnement S.A.

9.3. Republic Services, Inc.

9.4. Clean Harbors, Inc.

9.5. Suez S.A.

9.6. Waste Connections, Inc.

9.7. Stericycle, Inc.

9.8. Remondis SE & Co. KG

9.9. Biffa plc

9.10. Covanta Holding Corporation

9.11. Daiseki Co., Ltd.

9.12. FCC Environment

10. Appendix

10.1. Questionnaire

10.2. Related Reports

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates