Resources

About Us

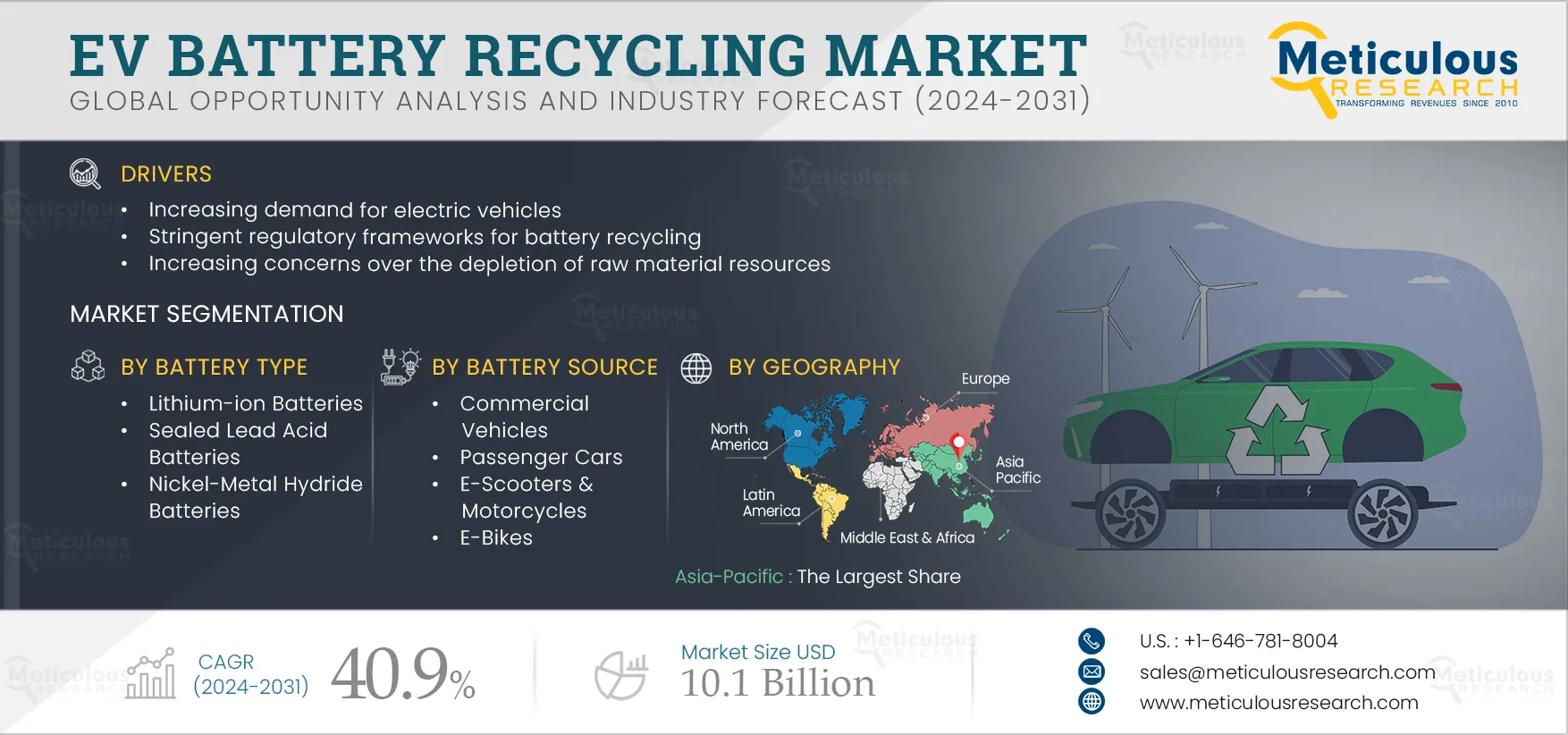

EV Battery Recycling Market Size, Share, Forecast, & Trends Analysis by Type (Li-ion), Source (Commercial, Passenger), Process (Pyro, Hydro), Model (Contractual, Direct-to-market), Material (Graphite, Lithium), and Geography - Global Forecast to 2031

Report ID: MRAUTO - 104799 Pages: 330 Sep-2024 Formats*: PDF Category: Automotive and Transportation Delivery: 24 to 48 Hours Download Free Sample ReportThe growth of the EV battery recycling market is primarily driven by the growing demand for Electric Vehicles (EVs), stringent regulations for battery recycling, and growing concerns over the depletion of raw materials used in EV battery production. However, safety concerns related to the handling and transportation of used batteries restrain the growth of this market.

Furthermore, government incentives aimed at encouraging the recycling of batteries and ongoing advances in battery recycling technologies are anticipated to generate growth opportunities for market stakeholders. However, the high costs of recycling electric vehicle batteries remain a major challenge for market players.

Additionally, rising investments in recycling infrastructure, particularly in developing countries, is a prominent trend in this market.

Click here to: Get a Free Sample Copy of this report

The conservation of vital natural resources has become imperative in today’s world, characterized by the growing demand for battery-powered devices and Electric Vehicles (EVs). The production of EV batteries requires substantial amounts of rare and valuable materials such as cobalt, nickel, and lithium. However, these materials are finite, and mining is expensive, with a significant environmental footprint.

According to Redwood Materials (U.S.), electrification is projected to increase the demand for lithium-ion batteries by over 500% by 2030. Furthermore, according to IEA (France), in 2022, the demand for lithium exceeded its supply despite a 180% increase in production since 2017. In 2022, EV battery manufacturing accounted for about 60% of the global demand for lithium, 30% of the demand for cobalt, and 10% of the demand for nickel. Five years earlier, in 2017, these shares were around 15%, 10%, and 2%, respectively. The mining and processing of these critical minerals requires a rapid scale-up to support the energy transition, not only for EVs but also for clean energy technologies.

The lithium, nickel, cobalt, and copper used in EV batteries have to be mined, which has a significant environmental impact. Hence, battery recycling infrastructure and capabilities require improvements to reduce the need to mine these materials. Millions of tons of batteries are expected to be decommissioned over the coming decades. By recycling the battery packs of end-of-life electric vehicles, materials can be extracted and reused to make smaller batteries (if the materials are usable) or battery components. Thus, EV battery recycling can reduce the need for new mining operations as the requirement for these materials will be reduced. Battery recycling not only helps conserve these precious resources but also reduces the environmental toll associated with their mining and processing.

The growing availability of charging infrastructure, government incentives for EV adoption, the decreasing total cost of EV ownership, and strategic developments in the EV industry are driving the adoption of electric vehicles across the globe. According to the World Economic Forum (Switzerland), in 2022, the global sales of electric cars increased by around 60% compared to 2021, exceeding 10 million units for the first time. According to a recent report by the International Energy Agency (IEA), in 2022, one in every seven passenger cars bought globally was an EV. In contrast, in 2017, just one in every 70 new cars sold was an EV. In addition, according to the Net Zero Emissions (NZE) by 2050 scenario, in 2030, electric car fleets are expected to account for approximately 60% of new car sales, with a volume of 300 million units.

Batteries or energy storage systems are essential for all electric vehicles, including Hybrid Electric Vehicles (HEVs) and Plug-in Hybrid Electric Vehicles (PHEVs). The widespread adoption of EVs requires adequate battery manufacturing and supply. EV batteries have a limited lifespan and eventually need to be replaced, resulting in a significant number of used batteries that need to be disposed of.

Electric vehicle batteries contain valuable materials such as lithium, cobalt, nickel, and manganese, which are limited resources. Recycling these materials helps conserve resources and reduce the need to mine and extract new materials, which can be costly and environmentally damaging. EV manufacturers require a lot of batteries, including lithium-ion batteries, to meet the growing demand for electric vehicles and continue the EV movement. Several companies are undertaking initiatives to cater to the growing demand for raw materials, achieve net-zero emissions goals, and reduce the amount of waste generated by EV batteries. Therefore, as EV adoption continues to grow, the recycling of used batteries is expected to become increasingly important to reduce the environmental impact of EVs and ensure the long-term sustainability of the EV industry.

Several companies across the globe are ramping up their battery recycling operations to promote sustainability in the lithium-ion battery sector. For instance, in April 2023, Glencore (Switzerland) partnered with FCC ÁMBITO, S.A.U. (Spain) and Iberdrola, S.A. (Spain) to provide lithium-ion battery recycling solutions at scale for Spain and Portugal. The partnership is aimed at tackling one of the biggest long-term challenges in the sector by recycling lithium-ion batteries through the establishment of a purpose-built facility. Also, in September 2023, Call2Recycle (U.S.) partnered with Panasonic Holdings Corporation (Japan) to launch a new initiative for recycling rechargeable batteries. Through this partnership, Panasonic and Call2Recycle aim to work with Panasonic's power tools customers to install Call2Recycle's collection boxes at plant assembly lines for gathering used rechargeable batteries from cordless tools. Users of Panasonic power tools in North America now have convenient access to battery recycling capabilities on the plant floor. Call2Recycle will recycle all rechargeable battery packs and cells, including Ni-MH (Nickel Metal Hydride), Ni-Cd (Nickel Cadmium), Ni-Zn (Nickel Zinc), Li-Ion (Lithium Ion), and SSLA/Pb (Small Sealed Lead Acid) up to 11 pounds.

Furthermore, in March 2022, Greenland Technologies Holding Corporation (UAE), a technology developer and manufacturer of industrial electric vehicles and drivetrain systems, partnered with Princeton NuEnergy Inc. (U.S.), a battery recycling company, to create a safe and sustainable recycling solution for end-of-life lithium-ion batteries used in industrial electric vehicles to minimize the environmental footprint. Such initiatives are expected to drive growth in the electric vehicle (EV) and battery manufacturing sectors while encouraging more sustainable practices and reducing their environmental footprint.

Improper disposal of batteries can lead to pollution and environmental degradation. Hence, countries across the globe are focused on optimizing battery recycling processes to prevent battery waste from being disposed of as municipal solid waste. In addition, battery recycling can help reduce the need to mine raw materials, benefiting the environment.

Governments around the world are introducing incentives for battery recycling. For instance, in December 2022, Nevada’s (U.S.) Office of Economic Development approved $105 million in tax incentives for the expansion of Redwood Materials’ lithium battery recycling plant in northern Nevada after the company announced plans to invest $1 billion in expanding its facility to accelerate the transition from fossil fuels to lithium batteries by localizing the supply chain. Also, in February 2022, the U.S. Department of Energy (DoE) issued two notices of intent to provide $2.91 billion to boost the production of advanced batteries that are critical to the rapidly growing clean energy industries of the future, including electric vehicles and energy storage, as directed by the Bipartisan Infrastructure Law. The Bipartisan Infrastructure Law will fund projects that bolster domestic battery manufacturing and recycling to support the growing demand for electric vehicles and energy storage.

Furthermore, governments are investing in EV battery recycling projects, creating market growth opportunities. For instance, in November 2022, the U.S. government announced $74 million in funding for ten projects to advance processes and technologies associated with lithium-ion battery recycling and reuse. Such developments are expected to increase battery recycling globally, creating market growth opportunities.

Based on battery type, the EV battery recycling market is segmented into lithium-ion batteries, sealed lead acid batteries, nickel-metal hydride batteries, and other batteries. In 2024, the lithium-ion batteries segment is expected to account for the largest share of 78.3% of the EV battery recycling market. The large market share of this segment can be attributed to the growing demand for electric vehicles, the rising need to manage the disposal of used batteries, the rapid depletion of raw material resources, and stringent regulatory frameworks for battery recycling. This segment is also projected to record the highest growth rate during the forecast period 2024–2031.

Based on battery source, the EV battery recycling market is segmented into commercial vehicles, passenger cars, e-scooters & motorcycles, and e-bikes. In 2024, the e-bikes segment is expected to account for the largest share of 64.8% of the EV battery recycling market. The large market share of this segment can be attributed to the rising adoption of e-bikes worldwide as a convenient and efficient alternative for short-distance commuting, increasing environmental concerns, a shift toward greener transportation, and increasing government incentives and subsidies for e-bike adoption.

However, the commercial vehicles segment is projected to register the highest growth rate during the forecast period 2024–2031. The growth of this segment is driven by the high demand for electric public transportation and logistics services, the surging need to manage the disposal of used batteries, the increasing demand for low-emission commuting, and the increasing government focus on implementing zero-emission commercial transportation.

Based on recycling process, the EV battery recycling market is segmented into direct physical recycling process, pyrometallurgical process, hydrometallurgical process, and other recycling processes. In 2024, the pyrometallurgical process segment is expected to account for the largest share of 42.6% of the EV battery recycling market. The large market share of this segment is attributed to the high recycling efficiency of the pyrometallurgical process, the increasing need to remove organic material from Li-ion batteries, the need for efficient and cost-effective recycling methods, the increasing need to recover valuable materials from used Li-ion batteries to reduce reliance on new mining operations, stringent environmental regulations, and the growing demand for scalable and flexible recycling processes.

However, the hydrometallurgical process segment is projected to witness the highest growth rate during the forecast period 2024–2031. The growth of this segment is driven by the increasing need to extract a wide range of materials, including copper, lithium, silver, nickel, and zinc, from EV batteries, the increasing need to address the shortage of critical raw materials, and the growing need to lower energy consumption, reduce waste, and minimize the environmental impact of recycling processes.

Based on business model, the EV battery recycling market is segmented into contractual recycling services and direct-to-market recycled materials. In 2024, the contractual recycling services segment is expected to account for the dominant share of over 86.0% of the EV battery recycling market. The large market share of this segment can be attributed to the growing government incentives and regulatory compliance requirements for battery recycling, the increasing need to manage the disposal of used batteries, the rising demand for more efficient and effective recycling through contractual partnerships, enterprises’ increasing need to manage and mitigate liabilities related to the handling, processing, and disposal of hazardous materials, and the rising need to reduce raw material costs in the manufacturing of new batteries. This segment is also projected to register the higher CAGR during the forecast period.

Based on material, the EV battery recycling market is segmented into graphite, nickel, cobalt, copper, manganese, lithium, aluminum, iron, plastics, and other materials. In 2024, the graphite segment is expected to account for the largest share of 18.5% of the EV battery recycling market. The large market share of this segment is attributed to its high recycling rate from Sealed Lead Acid (SLA) batteries and the increasing need to recover valuable materials from used EV batteries to reduce the need for mining new resources. Additionally, the widespread use of graphite as a key material in battery anodes, combined with ongoing research to improve its recyclability, also contributes to the significant market share of this segment.

However, the lithium segment is projected to witness the highest growth rate during the forecast period 2024–2031. The growth of this segment is driven by the increasing R&D and innovation in lithium-ion batteries, the rising demand for Electric Vehicles (EVs), and the growing need to address the shortage of critical raw materials in EV battery production.

Based on geography, the EV battery recycling market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2024, Asia-Pacific is expected to account for the largest share of 69.1% of the EV battery recycling market, followed by Europe, North America, Latin America, and the Middle East & Africa. Asia-Pacific's significant market share can be attributed to increasing investments in advanced recycling technologies and processes in countries including China, South Korea, and Japan to recover valuable metals and materials from used EV batteries, the high adoption of electric mobility, rising concerns regarding depleting precious and rare-earth metals, and the increasing implementation of new policies and regulations to promote the recycling of EV batteries and reduce environmental pollution.

However, the Middle East & Africa is slated to register the highest growth rate of 45.4% during the forecast period. The growth of this regional market is driven by the growing demand for lithium-ion batteries for EV production and the increasing volume of battery waste generated.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted during the past 3–4 years. The key players operating in the EV battery recycling market are Glencore plc (Switzerland), Fortum Corporation (Finland), Umicore NV (Belgium), Li-Cycle Holdings Corp. (Canada), Lithion Recycling Inc. (Canada), Tata Chemicals Limited (India), SNAM S.A.S. (France), Ascend Elements, Inc. (U.S.), ACE Green Recycling, Inc. (Singapore), Redwood Materials, Inc. (U.S.), Primobius GmbH (Germany), Attero Recycling Pvt. Ltd. (India), ACCUREC Recycling GmbH (Germany), Trishulavel Eshan Pvt. Ltd. (India), BatX Energies Pvt. Ltd. (India), MTB GROUP (France), and Duesenfeld GmbH (Germany).

|

Particulars |

Details |

|

Number of Pages |

330 |

|

Format |

|

|

Forecast Period |

2024–2031 |

|

Base Year |

2023 |

|

CAGR (Value) |

40.9% |

|

Market Size (Value) |

$10.1 Billion by 2031 |

|

Segments Covered |

By Battery Type

By Battery Source

By Recycling Process

By Business Model

By Material

|

|

Countries Covered |

Europe (Germany, U.K., Italy, France, Spain, Switzerland, Belgium, Norway, Poland, Finland, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Singapore, Australia & New Zealand, Malaysia, and Rest of Asia-Pacific), North America (U.S. and Canada), Latin America (Brazil, Mexico, and Rest of Latin America), and the Middle East & Africa (UAE, Saudi Arabia, and Rest of Middle East & Africa) |

|

Key Companies Profiled |

Glencore plc (Switzerland), Fortum Corporation (Finland), Umicore NV (Belgium), Li-Cycle Holdings Corp. (Canada), Lithion Recycling Inc. (Canada), Tata Chemicals Limited (India), SNAM S.A.S. (France), Ascend Elements, Inc. (U.S.), ACE Green Recycling, Inc. (Singapore), Redwood Materials, Inc. (U.S.), Primobius GmbH (Germany), Attero Recycling Pvt. Ltd. (India), ACCUREC Recycling GmbH (Germany), Trishulavel Eshan Pvt. Ltd. (India), BatX Energies Pvt. Ltd. (India), MTB GROUP (France), and Duesenfeld GmbH (Germany) |

The EV battery recycling market study focuses on market assessment and opportunity analysis based on revenues and developments across the segments and subsegments of the EV battery recycling market in various regions and countries. The study also includes a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last three to four years.

The EV battery recycling market is projected to reach $10.1 billion by 2031, at a CAGR of 40.9% during the forecast period.

In 2024, the pyrometallurgical process segment is expected to account for the largest share of 42.6% of the EV battery recycling market. The large market share of this segment is attributed to factors such as the increasing need to remove organic material from Li-ion batteries, the demand for efficient and cost-effective recycling methods, the increasing need to recover valuable materials from used Li-ion batteries to reduce the reliance on new mining operations, stringent environmental regulations, and the growing demand for scalable and flexible battery recycling processes.

The lithium segment is projected to witness the highest growth rate during the forecast period 2024–2031. This growth is driven by increasing innovation in lithium-ion batteries, the rising demand for Electric Vehicles (EVs), the shortage of critical raw materials for EV battery production, and supportive government regulations and policies empowering the EV sector.

The growth of this market is driven by several factors, including the growing demand for EVs, stringent regulations for battery recycling, and rising concerns about the depletion of raw materials used in EV battery production. Furthermore, government incentives aimed at promoting battery recycling and advances in battery recycling technologies are anticipated to generate market growth opportunities.

The key players operating in the EV battery recycling market are Glencore plc (Switzerland), Fortum Corporation (Finland), Umicore NV (Belgium), Li-Cycle Holdings Corp. (Canada), Lithion Recycling Inc. (Canada), Tata Chemicals Limited (India), SNAM S.A.S. (France), Ascend Elements, Inc. (U.S.), ACE Green Recycling, Inc. (Singapore), Redwood Materials, Inc. (U.S.), Primobius GmbH (Germany), Attero Recycling Pvt. Ltd. (India), ACCUREC Recycling GmbH (Germany), Trishulavel Eshan Pvt. Ltd. (India), BatX Energies Pvt. Ltd. (India), MTB GROUP (France), and Duesenfeld GmbH (Germany).

Asia-Pacific is expected to offer significant growth opportunities for the vendors in the EV battery recycling market during the analysis period. Ongoing investments in the EV sector and stringent regulatory frameworks aimed at improving waste management and EV battery recycling efficiency are contributing to the growth of this regional market.

Published Date: Jun-2024

Published Date: Apr-2022

Published Date: Apr-2022

Published Date: Sep-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates