Resources

About Us

Feed Forward Control & Closed Loop Adaptive Control Systems Market for Polymer FFF 3D Printing Size, Share, Forecast, & Trends Analysis by Offering (Hardware, Software), Control System Type (Feed Forward, Closed Loop), Printer Type (Industrial), End User (Aerospace & Defense, Healthcare) - Global Forecast to 2032

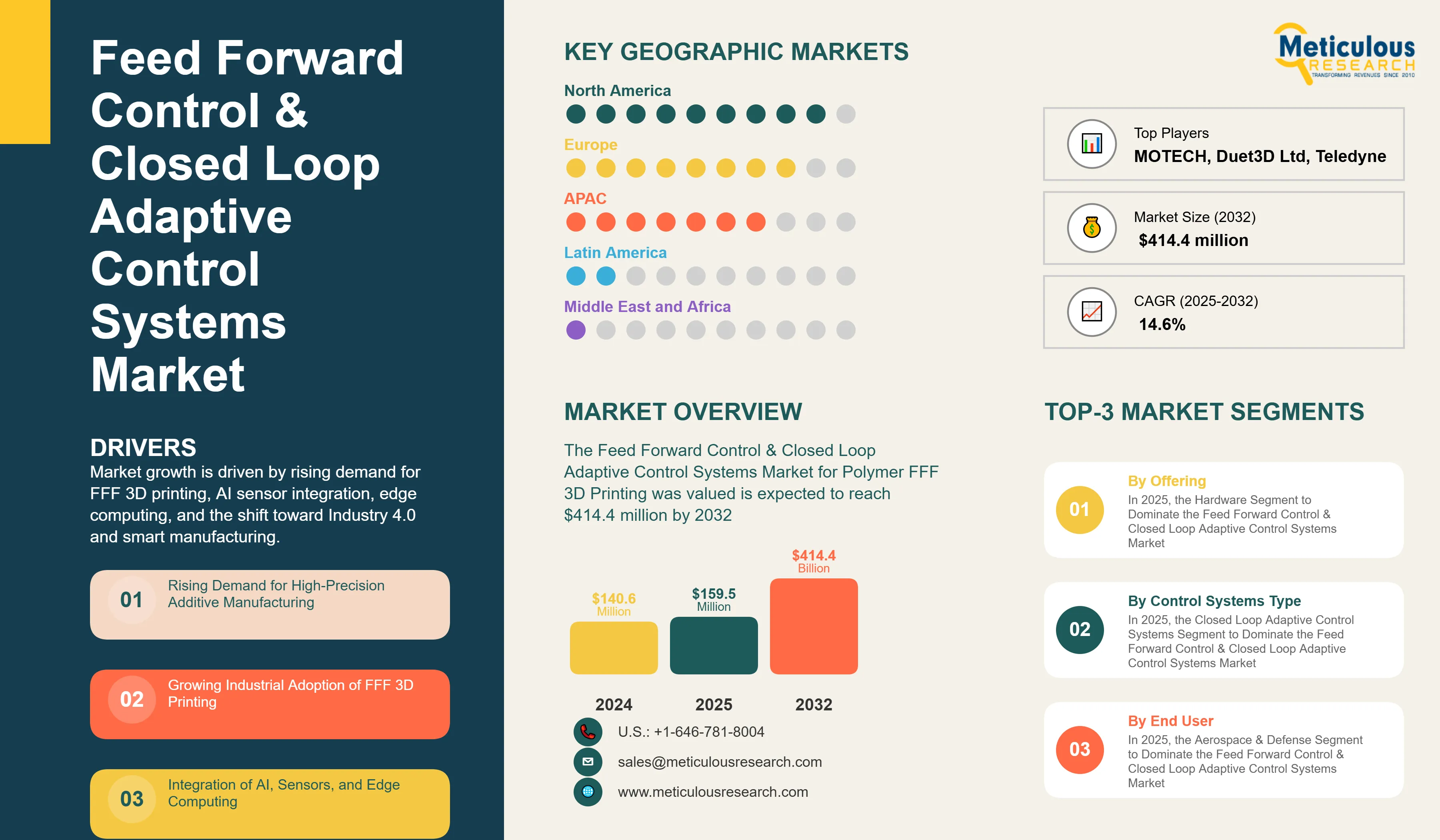

Report ID: MRSE - 1041548 Pages: 111 Aug-2025 Formats*: PDF Category: Semiconductor and Electronics Delivery: 2 to 4 Hours Download Free Sample ReportThe Feed Forward Control & Closed Loop Adaptive Control Systems Market for Polymer FFF 3D Printing was valued at $140.6 million in 2024. This market is expected to reach $414.4 million by 2032 from an estimated $159.5 million in 2025, at a CAGR of 14.6% during the forecast period from 2025 to 2032.

The growth of this market can be attributed to several factors, including rising demand for high-precision additive manufacturing, growing industrial adoption of FFF 3D printing, integration of AI sensors, and edge computing, and push toward industry 4.0 and smart manufacturing. However, the high cost of integration, limited standardization across platforms, and technical complexity and skill gaps restrains the growth of this market. Moreover, expansion into mid-volume production, customized control systems for OEMs and tier-one manufacturers, and emerging demand in regulated sectors are expected to support the market's growth.

Click here to: Get Free Sample Pages of this Report

Rising Demand for High-Precision Additive Manufacturing

Industries such as aerospace, medical devices, and automotive are increasingly relying on 3D printing for critical parts, where precision and dimensional accuracy are non-negotiable. Traditional open-loop FFF printing methods often suffer from issues like warping, layer misalignment, and inconsistent material deposition. Feed forward and closed loop adaptive control systems enable real-time monitoring and dynamic adjustments to parameters like temperature, extrusion rate, and print speed. This ensures higher precision and repeatability. As functional end-use part production gains momentum, the demand for these intelligent control systems grows, enabling manufacturers to meet stringent quality standards without compromising speed or cost-efficiency.

Growing Industrial Adoption of FFF 3D Printing

FFF (Fused Filament Fabrication) technology, once mainly used for prototyping, is increasingly being adopted for low- to mid-volume industrial production due to its cost-effectiveness and material versatility. As manufacturers shift toward end-use part production using FFF, consistency, mechanical performance, and repeatability become crucial. Conventional control approaches struggle to maintain these qualities over time and across multiple machines. Feed forward and adaptive control systems ensure stable thermal environments, precise filament flow, and correction of disturbances in real-time. This trend is especially significant in automotive, tooling, and industrial design applications, where FFF’s scalability must be matched with tighter process control to ensure product integrity.

Expansion Into Mid-Volume Production

As FFF 3D printing transitions beyond prototyping into small- and mid-volume production, industries like automotive, healthcare, and consumer goods demand higher consistency and dimensional fidelity. This shift creates a strong opportunity for adaptive control systems that can ensure tighter process control and improved part quality across batches. Manufacturers are increasingly evaluating FFF as a cost-effective alternative for custom, complex parts, but only if repeatability and traceability can be guaranteed. Feed forward and closed loop systems offer the technological leap needed to meet production-grade standards—opening doors to larger orders, regulated sectors, and high-value components previously out of reach for basic FFF setups.

Customized Control Solutions for OEMs and Tier-One Manufacturers

As OEMs and leading industrial users seek to integrate advanced 3D printing into their production workflows, they require highly tailored control architectures that fit seamlessly within proprietary hardware and software environments. This opens lucrative opportunities for control system vendors to offer modular, customizable platforms that align with Industry 4.0, enabling data integration, predictive analytics, and real-time process optimization. Collaborating directly with machine builders or Tier-1 suppliers allows vendors to embed control logic at the firmware or board level, creating differentiation and long-term service contracts. This B2B path promises higher margins, deeper client relationships, and long-term technology lock-ins.

By Offering: In 2025, the Hardware Segment to Dominate the Feed Forward Control & Closed Loop Adaptive Control Systems Market for Polymer FFF 3D Printing

Based on offering, the global feed forward control & closed loop adaptive control systems market for FFF polymer 3D printing is segmented into software, hardware, integrated platforms, and services. In 2025, the hardware segment is expected to account for the largest share of the feed-forward control & closed-loop adaptive control market for polymer FFF 3D printing. The large share of this segment is mainly attributed to the foundational role it plays in enabling real-time control capabilities. These systems rely heavily on physical components such as high-resolution sensors and monitoring systems, advanced hotends, optical & thermal monitoring cameras, and others to continuously monitor and adjust parameters like extrusion rate, nozzle temperature, print head movement, and bed leveling.

However, the software segment is projected to grow at the highest CAGR during the forecast period of 2025–2032, as manufacturers increasingly adopt AI- and ML-driven control algorithms, predictive modeling tools, and real-time data analytics to enhance print quality and reduce material waste. Software innovations offer greater flexibility, frequent updates, and integration with cloud and IoT platforms, which are essential for the dynamic and adaptive performance required in industrial 3D printing.

By Control Systems Type: In 2025, the Closed Loop Adaptive Control Systems Segment to Dominate the Feed Forward Control & Closed Loop Adaptive Control Systems Market for Polymer FFF 3D Printing

Based on control system type, the global feed forward control & closed loop adaptive control systems market for FFF polymer 3D printing is segmented into feed forward control systems, closed loop adaptive control systems, and hybrid control systems. In 2025, the closed loop adaptive control systems segment is expected to account for the largest share of the feed forward control & closed loop adaptive control market for polymer FFF 3D printing.

The large share and fast growth of this segment is mainly attributed to its ability to address critical quality and reliability challenges in real-time. Unlike feedforward systems, which rely on pre-programmed models to predict and adjust printing parameters, closed-loop systems continuously monitor the printing process using sensors such as thermal cameras, force sensors, and optical encoders, allowing for dynamic corrections to issues like under-extrusion, warping, and layer misalignment. This real-time responsiveness is particularly valuable in industrial and high-precision applications, where even minor defects can lead to part failure, material waste, or costly post-processing. As industries such as aerospace, automotive, and medical devices increasingly adopt FFF for end-use parts and functional prototypes, the demand for closed-loop systems has surged because they significantly improve first-pass yield and dimensional accuracy, especially when printing advanced engineering polymers like PEEK, PEKK, or carbon-fiber-reinforced filaments.

By Printer Type: In 2025, the Industrial FFF 3D Printers Segment to Dominate the Feed Forward Control & Closed Loop Adaptive Control Systems Market for Polymer FFF 3D Printing

Based on printer type, the global feed forward control & closed loop adaptive control systems market for FFF polymer 3D printing is segmented into industrial FFF 3D printers and desktop FFF 3D printers. In 2025, the industrial FFF 3D printers segment is expected to account for a larger share of the feed forward control & closed loop adaptive control market for polymer FFF 3D printing. The large share and rapid growth of this segment is mainly due to the critical need for precision, repeatability, and quality control in high-volume and high-value manufacturing applications. Industrial printers are widely used in aerospace, automotive, healthcare, and tooling sectors where print failures, dimensional inaccuracies, or material inconsistencies can lead to significant financial losses or safety risks. These applications demand real-time monitoring and intelligent correction of variables such as temperature, flow rate, speed, and layer adhesion—capabilities that are made possible through advanced control systems.

In contrast, desktop FFF printers, while benefiting from these technologies, primarily serve hobbyists, educators, and small businesses where extreme precision and material versatility are less critical, limiting their market share in advanced control system adoption.

By End User: In 2025, the Aerospace & Defense Segment to Dominate the Feed Forward Control & Closed Loop Adaptive Control Systems Market for Polymer FFF 3D Printing

Based on end user, the global feed forward control & closed loop adaptive control systems market for FFF polymer 3D printing is segmented into aerospace & defense, automotive, healthcare & medical devices, consumer goods, service bureaus, education & research institutions, and others. In 2025, the aerospace & defense segment is expected to account for the largest share of the feed forward control & closed loop adaptive control market for polymer FFF 3D printing. The large share of this end user segment is mainly attributed to stringent requirements for part accuracy, structural integrity, and regulatory compliance. Aerospace applications demand exceptionally high-performance polymer components that can withstand extreme temperatures, mechanical stress, and environmental conditions while meeting rigorous certification standards.

However, the healthcare & medical devices segment is projected to grow at the highest CAGR during the forecast period of 2025–2032. This segment's rapid growth is fueled by the increasing adoption of patient-specific solutions such as prosthetics, orthotics, surgical guides, and implants. These applications require a high level of customization, biocompatibility, and precision—factors that benefit significantly from real-time feedback and adaptive process control during 3D printing.

Asia-Pacific: Fastest-Growing Market

Based on geography, the global feed forward control & closed loop adaptive control systems market for FFF polymer 3D printing is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2025, the North America region is expected to account for the largest share of the global feed forward control & closed loop adaptive control systems market for FFF polymer 3D printing. The large share of this region is mainly due to concentration of advanced manufacturing industries, strong R&D infrastructure, and early adoption of cutting-edge additive manufacturing technologies. The region is home to leading aerospace, defense, and medical device companies that demand high-precision 3D printing solutions with sophisticated process control capabilities. Furthermore, substantial investments from both private enterprises and government initiatives, such as America Makes, have accelerated the development and implementation of smart manufacturing technologies. The presence of a mature industrial base with significant spending power enables North American manufacturers to readily adopt these advanced control systems despite their higher costs, reinforcing the region's market leadership.

However, the Asia-Pacific region is projected to grow at the highest CAGR during the forecast period of 2025–2032. This segment's rapid growth is driven by rapid industrialization, expanding manufacturing capabilities, and increasing investments in additive manufacturing infrastructure. Countries like China, Japan, and South Korea are aggressively adopting 3D printing for automotive, electronics, and consumer goods production, where efficiency and precision are becoming critical competitive factors. Government-led initiatives such as China's "Made in China 2025" and India's "National Strategy on Additive Manufacturing" are actively promoting smart manufacturing technologies, including adaptive control systems for FFF printing. Additionally, the growing presence of contract manufacturers and 3D printing service bureaus in the region is fueling demand for reliable, automated printing solutions to meet global supply chain needs.

Feed Forward Control & Closed Loop Adaptive Control Systems Market for Polymer FFF 3D Printing: Key Companies

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3–4 years. Some of the key players operating in the global feed forward control & closed loop adaptive control systems market for FFF polymer 3D printing are MOTECH Motor Co., Ltd. (China), Duet3D Ltd. (U.K.), Teledyne FLIR (U.S.), Raise3D Technologies, Inc. (China), Inkbit Corporation (U.S.), Shenzhen Rtelligent Technology Co., Ltd. (China), Prusa Research a.s. (Czech Republic), Bondtech AB (Sweden), Dyndrite Corporation (U.S.), Shenzhen BIQU Technology Co., Ltd. (China), E3D-Online Ltd. (U.K.), Beacon3D (U.S.), Stratonics, Inc. (U.S.), and Microswiss LLC (U.S.).

Feed Forward Control & Closed Loop Adaptive Control Systems for Polymer FFF 3D Printing Industry Overview: Latest Developments from Key Industry Players

|

Particulars |

Details |

|

Number of Pages |

111 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

14.6% |

|

Market Size (Value) |

USD 414.4 Million by 2032 |

|

Segments Covered |

By Offering

By Control System Type

By Printer Type

By End User

|

|

Regions Covered |

North America, Asia-Pacific, Europe, Latin America, and the Middle East & Africa. |

|

Key Companies |

MOTECH Motor Co., Ltd. (China), Duet3D Ltd. (U.K.), Teledyne FLIR (U.S.), Raise3D Technologies, Inc. (China), Inkbit Corporation (U.S.), Shenzhen Rtelligent Technology Co., Ltd. (China), Prusa Research a.s. (Czech Republic), Bondtech AB (Sweden), Dyndrite Corporation (U.S.), Shenzhen BIQU Technology Co., Ltd. (China), E3D-Online Ltd. (U.K.), Beacon3D (U.S.), Stratonics, Inc. (U.S.), and Microswiss LLC (U.S.). |

This global feed forward control & closed loop adaptive control systems market for polymer FFF 3D printing report provides detailed market insights and market size & forecasts in terms of value by offering, control system types, printer type, end user, and geography. Each segment provides the market size & forecast for five key geographies (North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa) along with the key countries.

The feed forward control & closed loop adaptive control systems market for polymer FFF 3D printing is projected to reach $414.4 million by 2032, at a CAGR of 14.6% during the forecast period 2025–2032.

The hardware segment is expected to hold the major share of the market in 2025.

The healthcare & medical devices segment is projected to record the highest growth rate during the forecast period 2025–2032.

The growth of this market is driven by rising demand for high-precision additive manufacturing, growing industrial adoption of FFF 3D printing, integration of AI sensors, and edge computing, and push toward industry 4.0 and smart manufacturing. Furthermore, expansion into mid-volume production, customized control systems for OEMs and tier-one manufacturers, and emerging demand in regulated sectors are expected to support the market's growth.

The key players operating in the global feed forward control & closed loop adaptive control systems market for polymer FFF 3D printing are MOTECH Motor Co., Ltd. (China), Duet3D Ltd. (U.K.), Teledyne FLIR (U.S.), Raise3D Technologies, Inc. (China), Inkbit Corporation (U.S.), Shenzhen Rtelligent Technology Co., Ltd. (China), Prusa Research a.s. (Czech Republic), Bondtech AB (Sweden), Dyndrite Corporation (U.S.), Shenzhen BIQU Technology Co., Ltd. (China), E3D-Online Ltd. (U.K.), Beacon3D (U.S.), Stratonics, Inc. (U.S.), and Microswiss LLC (U.S.).

The emerging countries from the Asia-Pacific is expected to offer significant growth opportunities for vendors in the feed forward control & closed loop adaptive control systems market for polymer FFF 3D printing during the forecast period.

Published Date: Sep-2025

Published Date: Jul-2025

Published Date: Oct-2024

Published Date: Oct-2022

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates