Resources

About Us

Digital Biomanufacturing Market Size, Share, Forecast, & Trends Analysis by Offering (Software [PAT, MES, Digital Twin] Hardware), Functionality (Product Design, Analytics, Automation), Applicatison (MAB, Protein, Vaccine), and Bioprocess - Global Forecast to 2035

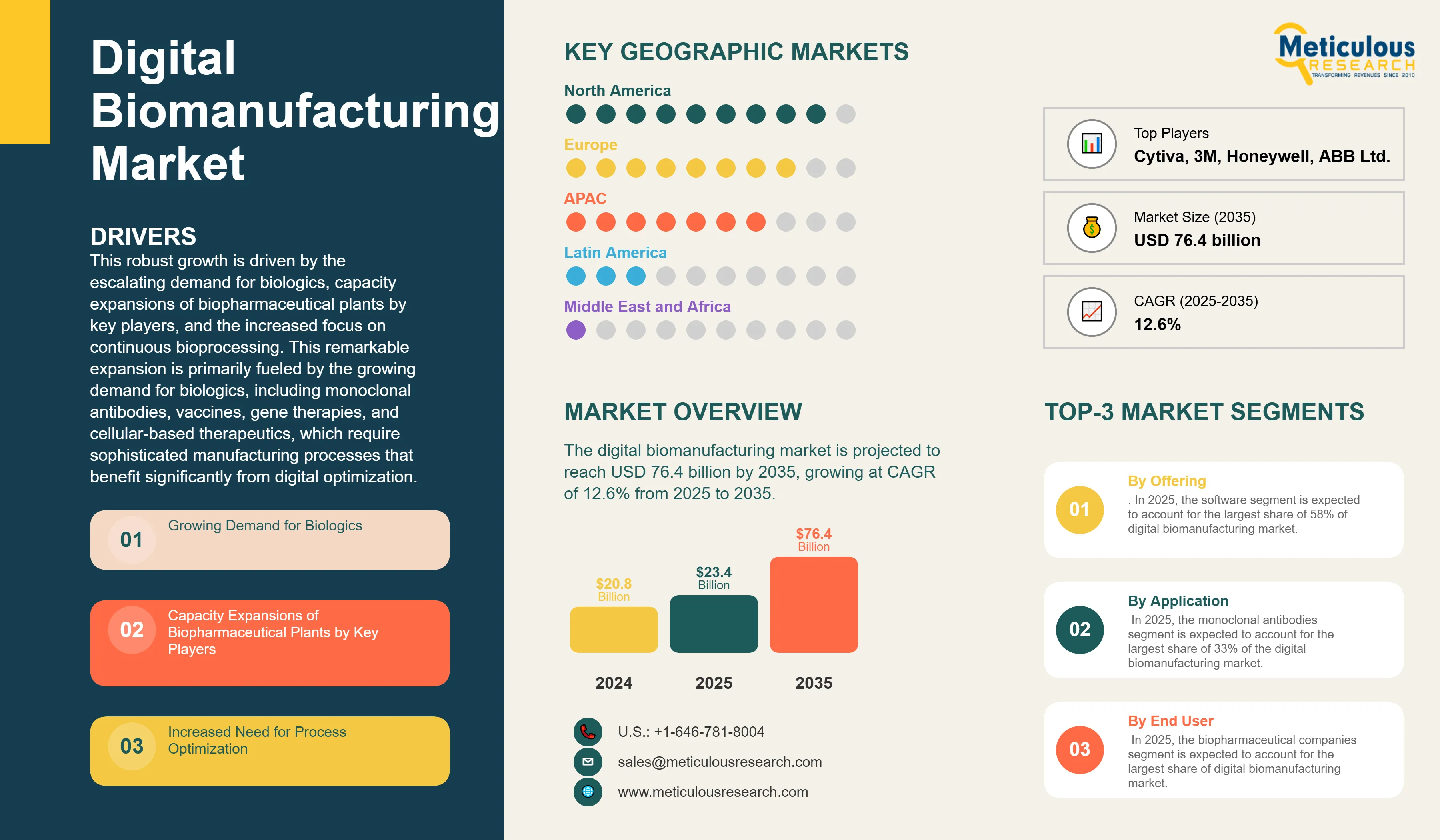

Report ID: MRHC - 1041288 Pages: 300 Nov-2025 Formats*: PDF Category: Healthcare Delivery: 2 to 4 Hours Download Free Sample ReportThe digital biomanufacturing market is projected to reach USD 76.4 billion by 2035 from an estimated USD 23.4 billion in 2025, growing at CAGR of 12.6% from 2025 to 2035.

This robust growth is driven by the escalating demand for biologics, capacity expansions of biopharmaceutical plants by key players, and the increased focus on continuous bioprocessing. This remarkable expansion is primarily fueled by the growing demand for biologics, including monoclonal antibodies, vaccines, gene therapies, and cellular-based therapeutics, which require sophisticated manufacturing processes that benefit significantly from digital optimization. The shift towards personalized medicine and the rise of advanced therapy medicinal products (ATMPs) further amplify the need for flexible, scalable, and data-driven manufacturing approaches that can adapt to diverse production requirements while maintaining regulatory compliance.

However, the market's growth faces notable challenges. The high cost of technology deployment presents a significant barrier, particularly for smaller biotechnology companies and contract development and manufacturing organizations (CDMOs) operating on limited budgets. Additionally, the complex development and manufacturing processes of biopharmaceuticals, coupled with stringent regulatory requirements, create implementation complexities that require substantial expertise and validation efforts. Integration challenges with existing legacy systems and concerns about data security and intellectual property protection also pose restraints to widespread adoption.

Click here to: Get Free Sample Pages of this Report

Growing Demand for Biologics

The leading factor for digital biomanufacturing adoption is the exponential increase in biologics demand worldwide. Biologic drugs, in particular, monoclonal antibodies, cell and gene therapies, and biosimilars, have become the pillars of the new therapeutic treatments in oncology, immunology, and rare disease areas. Such a demand surge puts a lot of stress on the manufacturing capacity and efficiency of the process.

Through digital technologies, manufacturers are able to scale up their capacity in a more efficient manner without losing quality and consistency of the product. For instance, digital twins give a pharmaceutical company an opportunity to simulate and optimize production scenarios before making physical changes, thus cutting the time required to reach the market and the risks to decrease. Manufacturing Execution Systems (MES) enable the visibility of production workflows in real-time, thus the demand variations can be responded quickly and the resources can be allocated effectively.

Biologics manufacturing process is complicated, which is why it utilizes living cell systems and goes through a complex purification process. Therefore, sophisticated monitoring and control mechanisms are required which traditional manufacturing methods cannot provide. Digitally enabled biomanufacturing platforms give the required vastness and adaptability to meet market demands that keep on changing while guaranteeing therapeutic effect and safety.

Capacity Expansions of Biopharmaceutical Plants by Key Players

Major pharmaceutical industries are pouring a considerable amount of money into developing their biomanufacturing capabilities. One of the main aspects that play a central role in their capacity enhancement initiatives is the use of digital technologies. It is not only about adding to the physical infrastructure but also about building smart, interconnected manufacturing ecosystems that can be versatile and efficient in agriculture.

Use of digital biomanufacturing allows companies to achieve the highest possible utilization of their extended facilities, through advanced process optimization and predictive maintenance made possible by digital technologies. The introduction of Process Analytical Technology (PAT) during plant expansions is essential for quality monitoring and control in real-time, thus lowering the occurrence of batch failures and enhancing overall equipment effectiveness (OEE).

One of the benefits companies get from the adoption of digital solutions in capacity expansion projects is the competitive advantage that encompasses a shorter commissioning period, quicker technology transfer, and better operational flexibility. The companies which thoroughly employ the digital strategies in their direction confess the considerable increase of production yield, the decline of manufacturing costs, and the facilitation of regulatory compliance capabilities.

Need for Process Optimization in Biomanufacturing

Process optimization involves improving manufacturing by incorporating quality monitoring, machinery, and maintenance, among other factors, to optimize costs and increase productivity. The biomanufacturing process is enhanced by process optimization through the identification and resolution of bottlenecks and the assurance of product quality. Process optimization techniques like design of experiments (DoE), statistical process control (SPC), and process analytical technology (PAT), assist biomanufacturers in reducing manufacturing costs and time for the biologics production by incorporating real time monitoring, continuous processing, and data capturing & analysis.

Biomanufacturing is an expensive method due to the need for specific culture conditions, costly media, and feed. The rising preference for biopharmaceuticals is driving the increased need for process optimization to achieve better yield and product quality. Thus, to scale up the business and to meet growing market demand biopharmaceutical manufacturers are increasing the adoption of process optimization techniques.

Digital Biomanufacturing Market Trends

Integration of Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning technologies are increasingly being integrated into biomanufacturing operations to enable autonomous decision-making and continuous process optimization. These technologies analyze vast amounts of manufacturing data to identify patterns, predict outcomes, and recommend process improvements that human operators might not recognize. AI-powered systems can optimize multiple process parameters simultaneously while considering complex interdependencies that traditional control approaches cannot handle effectively.

Machine learning algorithms are being deployed for predictive quality control, where models trained on historical manufacturing data can predict final product quality based on real-time process measurements. This capability enables proactive quality management and reduces the risk of producing out-of-specification products. Advanced AI systems can also predict equipment failures before they occur, enabling predictive maintenance strategies that minimize unplanned downtime and extend equipment life.

Cloud-Based Manufacturing Platforms

The adoption of cloud-based platforms for biomanufacturing is accelerating as companies recognize the benefits of scalable computing resources, enhanced collaboration capabilities, and reduced IT infrastructure costs. Cloud platforms enable real-time data sharing between manufacturing facilities, research laboratories, and corporate headquarters, facilitating improved decision-making and knowledge transfer.

Cloud-based digital twin platforms allow companies to develop and optimize manufacturing processes using scalable computing resources without significant on-premises infrastructure investments. These platforms also enable collaborative process development where multiple teams can contribute to process optimization efforts simultaneously. The availability of cloud-based analytics tools democratizes access to advanced data analysis capabilities across the organization

Digital Biomanufacturing Market Opportunity

Shift Towards Bioprocessing 4.0

The biopharmaceutical industry is shifting towards Bioprocessing 4.0 (a term derived from Industry 4.0), a national strategic initiative launched by the German government in 2010. Biomanufacturing 4.0 is still in its initial stage. Bioprocessing 4.0 is defined as an end-to-end connected bioprocess, where all equipment and systems in the process are connected digitally through the industrial-internet-of-things (IIoT) to run, control, and enhance processes through feedback loops, machine learning, and artificial intelligence (AI). Digital transformation has become necessary in the biopharmaceutical industry as it provides the competitive advantage and opportunity for streamlining the production process. Digital biomanufacturing uses IoT to connect different data sources, equipment, and materials for process optimization. In combination with digital biomanufacturing solutions the adoption of bioprocessing 4.0 is gradually increasing. Many biopharmaceutical manufactures are shifting towards bioprocessing 4.0 to reduce the manual intervention during drug testing and monitoring which saves time and reduces the risk of errors and cross-contamination, thus boosting production.

Digital Biomanufacturing Market Analysis: Key Findings

By Offering: The Software Segment to Dominate the Digital Biomanufacturing Market in 2025

Based on offering, the digital biomanufacturing market is segmented into software and hardware. In 2025, the software segment is expected to account for the largest share of 58% of digital biomanufacturing market. The software segment's dominance is rooted in its position as the fundamental enabler of digital transformation in biomanufacturing operations. It serves as the core intelligence layer that drives process optimization, data analytics, and real-time decision-making across all biomanufacturing processes. This includes sophisticated process analytical technology (PAT) systems, advanced data analysis software, manufacturing execution systems (MES), and cutting-edge digital twin platforms that create virtual replicas of bioprocessing operations.

The software segment is also expected to witness a rapid growth during the forecast period, driven by the continuous evolution of artificial intelligence and machine learning capabilities embedded within these platforms. Modern biomanufacturing software is transitioning from simple monitoring and control systems to intelligent platforms capable of predictive analytics, autonomous process adjustments, and cognitive decision-making.

By Functionality: The Process Optimization & Analytics Segment to Dominate the Digital Biomanufacturing Market in 2025

Based on functionality, the digital biomanufacturing market is segmented into product design, process optimization & analytics, automation & control, and other applications. In 2025, the process optimization & analytics segment is expected to account for the largest share of digital biomanufacturing market. This segment's dominance reflects the critical need for continuous improvement in biomanufacturing processes, where even minor optimizations can result in significant cost savings, yield improvements, and quality enhancements.

Process optimization & analytics encompasses advanced statistical process control, design of experiments (DoE), multivariate data analysis, and machine learning-powered optimization algorithms that continuously analyze process parameters to identify opportunities for improvement. These systems integrate data from multiple sources across the bioprocessing workflow to provide comprehensive insights into process performance, enabling manufacturers to achieve higher product yields, reduce batch-to-batch variability, and minimize production costs while maintaining regulatory compliance.

However, the supply chain & operations management segment is witnessing the fastest growth, with a CAGR of 16.5%, as biomanufacturing companies increasingly recognize the importance of end-to-end visibility and coordination across their global operations. This rapid growth is driven by the complexity of modern biopharmaceutical supply chains, which often involve multiple manufacturing sites, diverse raw material suppliers, and stringent cold-chain requirements.

By Bioprocess: The Upstream Bioprocess Segment to Dominate the Digital Biomanufacturing Market in 2025

Based on bioprocess, the digital biomanufacturing market is segmented into upstream bioprocess and downstream bioprocess. In 2025, the upstream bioprocess segment is expected to account for the largest share of the digital biomanufacturing market. The upstream segment's dominance due to its fundamental role as the foundation of all biomanufacturing operations and its significant impact on overall process economics. Upstream processes directly influence product yield, quality, and consistency, making optimization in this area particularly valuable. The complexity of cell culture processes, with their numerous interdependent variables including pH, dissolved oxygen, temperature, nutrient levels, and metabolite concentrations, creates substantial opportunities for digital optimization. Advanced process analytical technology, real-time monitoring systems, and AI-powered control algorithms can significantly improve cell productivity, reduce contamination risks, and optimize media consumption.

By Application: The Monoclonal Antibodies Segment to Dominate the Digital Biomanufacturing Market in 2025

Based on application, the digital biomanufacturing market is segmented into monoclonal antibodies, recombinant hormones/proteins, vaccines, cellular-based biologics, and gene-based biologics. In 2025, the monoclonal antibodies segment is expected to account for the largest share of 33% of the digital biomanufacturing market. The large share of monoclonal antibodies segment is attributed to the established manufacturing infrastructure, well-understood production processes, and significant commercial value of these products. The complex multi-step production process of monoclonal antibodies, involving cell line development, upstream cell culture, downstream purification, formulation, and fill-finish operations, creates numerous opportunities for digital optimization. The high value and large production volumes of monoclonal antibodies justify substantial investments in advanced digital technologies that can improve yields, reduce production costs, and ensure consistent product quality.

However, the gene-based biologics segment is experiencing the fastest growth, with a CAGR of 17.9%, as this emerging therapeutic modality gains regulatory approval and commercial traction. Gene-based biologics, including gene therapies and viral vectors, represent a rapidly expanding frontier in biopharmaceuticals, with the FDA anticipating approval of 10 to 20 cell and gene therapy products per year by 2025.

By End User: The Biopharmaceutical Companies Segment to Dominate the Digital Biomanufacturing Market in 2025

Based on end-user, the digital biomanufacturing market is segmented into biopharmaceutical companies, academic and research institutes, and CDMO & CROs. In 2025, the biopharmaceutical companies segment is expected to account for the largest share of digital biomanufacturing market. The increasing preference for biopharmaceuticals, increasing research in personalized medicines, and supportive initiatives for the adoption of biopharmaceuticals are supporting the segment’s largest market share. Biopharmaceuticals are typically complex and costlier than the conventional drugs to manufacture. To reduce the errors in manufacturing and scale-up production process, biomanufacturing industries are deploying digital solutions to increase the production of biologics. The increasing number of biopharmaceutical companies along with gradually increasing adoption of digital technologies in biopharmaceutical companies is contributing to the largest share of the segment. For instance, around 55% of companies incorporated digital technologies in the workflow. (Source: Global Pharma Tek, U.S.)

Geographical Analysis

North America to Dominate the Market in 2025

In 2025, North America is expected to account for the largest share of 38% of the digital biomanufacturing market. The large share of this region is attributed to the presence of leading biopharmaceutical companies, advanced technological infrastructure, substantial R&D investments, and supportive regulatory environment. The United States, in particular, hosts numerous biotechnology hubs and maintains a leadership position in biologics development and manufacturing.

North America's established biopharmaceutical ecosystem includes major companies with extensive manufacturing networks, well-developed supply chains, and significant financial resources for technology adoption. The region's regulatory framework, led by the FDA, has been progressive in encouraging the adoption of advanced manufacturing technologies and providing guidance on digital technologies in biomanufacturing. Additionally, the concentration of leading technology providers and consulting firms in North America facilitates rapid adoption and implementation of digital solutions.

However, Asia-Pacific is experiencing the fastest growth, with a CAGR of 16.0%, driven by rapidly expanding biopharmaceutical sectors in countries such as China, India, Japan, and South Korea. The region's growth is fueled by increasing government investments in biotechnology, growing domestic demand for biologics, expanding manufacturing capacity, and the presence of cost-effective CDMOs.

Digital Biomanufacturing Market: Key Companies

The report offers a competitive landscape based on an extensive assessment of the product offerings and geographic presence of leading market players and the key growth strategies adopted by them over the past few years (2023–2025). The key players operating in the global digital biomanufacturing market are GE Healthcare Technologies Inc. (U.S.), Siemens Xcelerator (Subsidiary of Siemens) (Germany), Cytiva (Subsidiary of Danaher corporation) (U.S.), ABB Ltd. (Switzerland), Sanofi S.A. (France), Emerson Electric co. (U.S.), Honeywell International, Inc. (U.S.), SAP SE (Germany), OVO Biomanufacturing Inc. (U.S.), Schneider Electric SE (France), Dassault Systèmes (France), Oracle Corporation (U.S.), and 3M (U.S.).

Digital Biomanufacturing Market Overview: Latest Developments from Key Industry Players

|

Particulars |

Details |

|

Number of Pages |

226 |

|

Format |

|

|

Forecast Period |

2025-2035 |

|

Base Year |

2024 |

|

CAGR |

12.4% |

|

Estimated Market Size (2025) |

$23.4 billion |

|

Forecasted Market Size (2035) |

$76.4 billion |

|

Segments Covered |

Digital Biomanufacturing Market Assessment—by Offering

Digital Biomanufacturing Market Assessment—by Functionality

Digital Biomanufacturing Market Assessment—by Bioprocess

Digital Biomanufacturing Market Assessment—by Application

Digital Biomanufacturing Market Assessment—by End-user

|

|

Countries Covered |

North America (U.S. and Canada), Europe (Germany, France, U.K., Italy, Spain, Switzerland, Denmark, Ireland, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, Australia, South Korea, and Rest of Asia-Pacific), Latin America (Brazil, Mexico, Rest of Latin America), and Middle East & Africa. |

|

Key Companies |

The key players operating in the global digital biomanufacturing market are GE Healthcare Technologies Inc. (U.S.), Siemens Xcelerator (subsidiary of Siemens) (Germany), Cytiva (subsidiary of Danaher Corporation) (U.S.), ABB Ltd. (Switzerland), Sanofi S.A. (France), Emerson Electric Co. (U.S.), Honeywell International, Inc. (U.S.), SAP SE (Germany), OVO Biomanufacturing. (U.S.), Schneider Electric SE (France), Dassault Systemes (France), Oracle Corporation (U.S.), and 3M (U.S.). |

The global digital biomanufacturing market report covers the qualitative and quantitative analysis of the digital biomanufacturing market. This report involves the analysis of various segments of digital biomanufacturing such as offering, functionality, bioprocess, and end-user at the regional and country level. The report also provides insights on factors impacting market growth, regulatory analysis, pricing analysis, and Porter’s five forces analysis.

The digital biomanufacturing market is projected to reach USD 76.4 billion by 2035 from an estimated USD 23.4 billion in 2025, growing at CAGR of 12.6% from 2025 to 2035.

Among all the offerings studied in this report, the software segment is expected to account for the largest share of 57% the digital biomanufacturing market in 2025. The rising need for process optimization in the biomanufacturing industry is increasing the demand for software. Software deployment helps in evaluating product and process quality with real time monitoring, data management, and prediction-based outcomes. It helps to streamline the process of biomanufacturing.

The growth of this market can be attributed to several factors such as, growing demand for biologics, capacity expansions of biopharmaceutical plants by key players, increased need for process optimization, increased focus on quality standards & regulatory compliance, strong R&D pipeline for biopharmaceuticals, and rising focus on continuous bioprocessing. However, the excessive cost of technological deployment, complex development, and manufacturing process of biopharmaceuticals are restraining the market growth.

The key players operating in the global digital biomanufacturing market are GE Healthcare Technologies Inc. (U.S.), Siemens Xcelerator (subsidiary of Siemens) (Germany), Cytiva (subsidiary of Danaher Corporation) (U.S.), ABB Ltd. (Switzerland), Sanofi S.A. (France), Emerson Electric co. (U.S.), Honeywell International, Inc. (U.S.), SAP SE (Germany), OVO Biomanufacturing. (U.S.), Schneider Electric SE (France), Dassault Systems (France), Oracle Corporation (U.S.), and 3M (U.S.).

The market in Asia-Pacific is slated to register the highest growth rate of 16.0% during the forecast period. The countries in Asia-Pacific, including China, India, and South Korea, are projected to offer significant growth opportunities for the vendors in this market. This is attributed to factors such as the rising number of biopharmaceutical companies, growing patient population, increasing disposable income, and rising foreign direct investments (FDI) for biopharmaceutical companies.

Published Date: Jan-2025

Published Date: Nov-2024

Published Date: Jul-2024

Published Date: Nov-2022

Published Date: Mar-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates