Resources

About Us

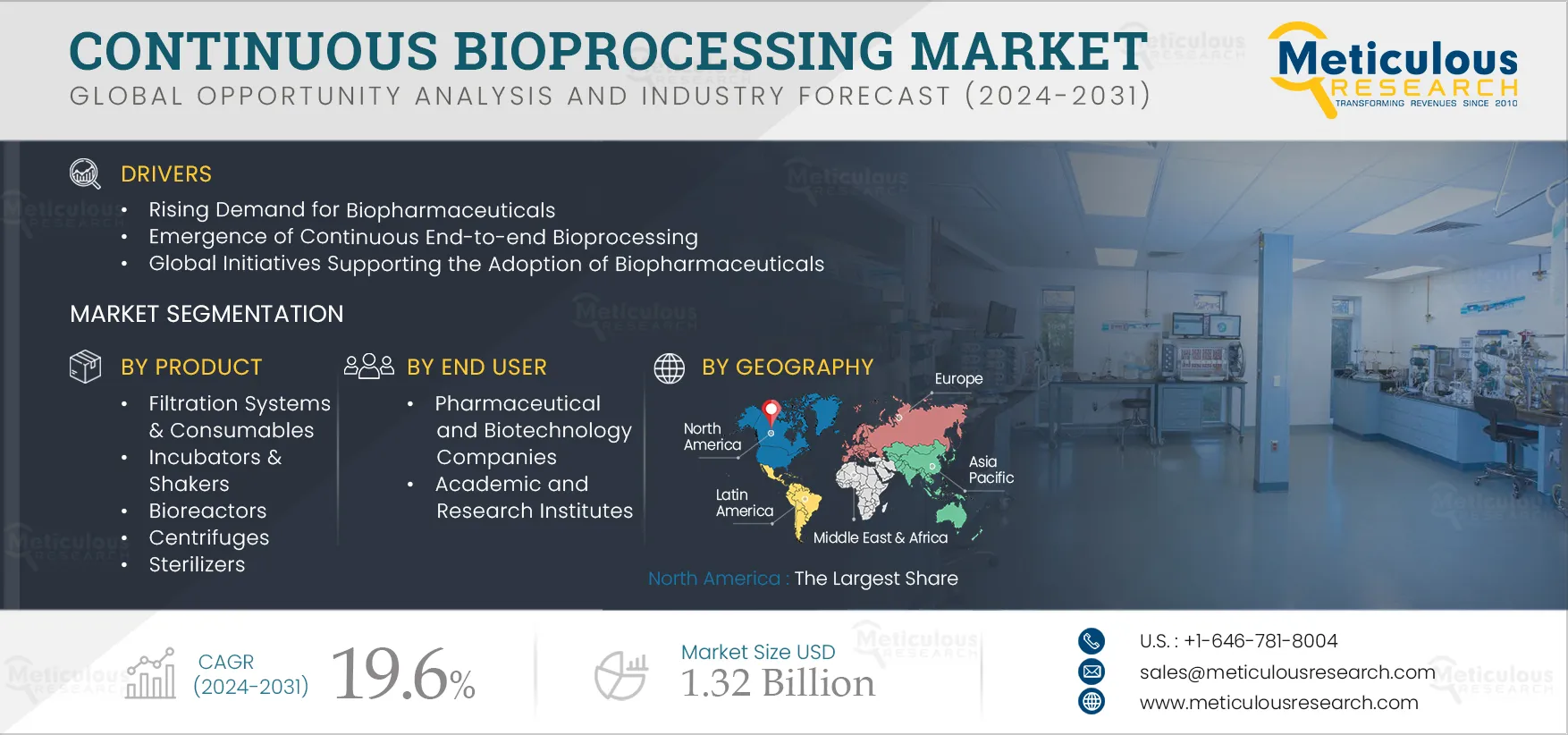

Continuous Bioprocessing Market by Product (Filtration, Chromatography, Bioreactor, Incubator, Centrifuge, Reagents) Process (Upstream, Downstream) Application (Monoclonal Antibodies, Vaccines, Plasma Fractionation, R&D) End User - Global Forecast to 2031

Report ID: MRHC - 104380 Pages: 220 Mar-2024 Formats*: PDF Category: Healthcare Delivery: 24 to 48 Hours Download Free Sample ReportContinuous bioprocessing consists of integrated continuous unit processes without intermediate holding tanks through which product travels into containers in a constant flow. Continuous unit operations are characterized by extremely intensified processing with short downtimes. An end-to-end bioprocess involves a perfusion bioreactor, multi-column chromatography systems, and multi-column intermediate purification. Some pharmaceutical and biopharmaceutical manufacturers adopt a hybrid approach for continuous biopharmaceutical manufacturing in which only the upstream or downstream process is continuous.

The growth of the continuous bioprocessing market is driven by the rising demand for biopharmaceuticals, the emergence of continuous end-to-end bioprocessing, global initiatives supporting the adoption of biopharmaceuticals, and the advantages of continuous manufacturing over fed-batch processes. However, high capital investment requirements and operational complexities in continuous bioprocessing restrain the growth of this market.

Furthermore, Bioprocessing 4.0 and the increasing use of continuous bioprocessing for monoclonal antibody production are expected to generate growth opportunities for the stakeholders in this market. However, cross-contamination risks and process development control are major challenges impacting market growth.

The demand for biopharmaceuticals is rising due to their ability to target specific molecules, their lower side effects, and their high activity and specificity. Biopharmaceuticals are increasingly being used for treating Immune-mediated Inflammatory Diseases (IMIDs), including Rheumatoid Arthritis (RA), Inflammatory Bowel Disease (IBD), and cancer. The gradual increase in approvals for biopharmaceuticals also supports the growth of this market. According to the U.S. FDA, out of the total drugs approved in 2022, 15 were biologics, compared to 13 in 2020.

The implementation of continuous manufacturing processes in commercial manufacturing improves productivity and decreases manufacturing costs, reducing the prices of biopharmaceutical products, making medicines more accessible, and improving the quality of care. Continuous bioprocessing is transforming biopharmaceutical manufacturing. The benefits of continuous flow manufacturing, such as increased process design flexibility, improved process economics, easy scale-up, and short development times, are boosting the adoption of continuous bioprocessing in biopharmaceutical production.

Furthermore, government initiatives supporting the adoption of biopharmaceuticals are driving the continuous bioprocessing market. For instance, in September 2022, the U.S. government announced an investment of $2 billion in a biomanufacturing initiative aimed at expanding and improving the domestic biopharmaceutical manufacturing capacity. Also, in August 2023, the U.K. government invested $16.3 million (€15 million) in the country’s biopharmaceutical manufacturing industry via its national innovation agency. The investment was aimed at supporting the country's life sciences sector.

Continuous manufacturing is a new trend in the manufacturing industry. Industries are adopting continuous manufacturing to improve efficiencies and increase profits. Although batch manufacturing is currently the most preferred manufacturing method, continuous biomanufacturing is being increasingly accepted in the pharmaceutical industry due to the commercial advantages it offers over batch manufacturing. Some of the advantages of continuous-flow manufacturing are as follows:

Click here to: Get Free Sample Pages of this Report

Based on product, the continuous bioprocessing market is segmented into filtration systems & consumables, chromatography systems & consumables, bioreactors, sterilizers, centrifuges, incubators & shakers; cell culture media, buffers, and reagents; and other instruments & consumables. In 2024, the filtration systems & consumables segment is expected to account for the largest share of the continuous bioprocessing market. The segment’s large market share is attributed to the high reliance on filtration systems in bioprocessing separation techniques, the reusability of filters across every step in bioprocessing, and the need for high cell densities in controlling the bioburden in biopharmaceuticals. Key market players are focused on developing technologically advanced filtration systems to cater to the growing demand. For instance, in November 2022, High Purity New England (U.S.) launched the OptiMaxx Tangential Flow Filtration (TFF) system. The filtration system offers simplicity of use for biomanufacturing and is customizable.

Based on process type, the continuous bioprocessing market is segmented into upstream processes and downstream processes. In 2024, the downstream processes segment is expected to account for the larger share of the continuous bioprocessing market. Downstream processing is an integral part and the largest process segment in continuous bioprocessing. Additionally, advancements in downstream processing, such as the introduction of multi-column chromatography and single-pass tangential flow filtration, support the segment’s large market share. Further, ultra-scale-down bioprocessing is a recent trend in downstream processing for rapid process development and optimization in biopharmaceutical manufacturing.

Based on application, the continuous bioprocessing market is segmented into commercial applications and R&D applications. The R&D applications segment is expected to register the higher CAGR during the forecast period. The high growth of this segment is driven by the increasing clinical studies for monoclonal antibodies, gene therapies, and vaccines. The increasing importance of biopharmaceuticals (including monoclonal antibodies) and the growing focus on R&D to develop vaccines and therapies are driving the growth of this segment. For instance, in March 2023, the U.S. government invested $31.9 billion in mRNA vaccine research and procurement.

Based on end user, the continuous bioprocessing market is segmented into pharmaceutical & biotechnology companies, CDMOs & CROs, and academic & research institutes. In 2024, the pharmaceutical & biotechnology companies segment is expected to account for the largest share of the continuous bioprocessing market. The segment’s large market share is attributed to the need to develop new therapies owing to increasing disease prevalence and the increased spending on pharmaceutical R&D. For instance, according to the International Federation of Pharmaceutical Manufacturers & Associations (IFPMA), global pharmaceutical R&D expenditure is expected to reach $213 billion in 2026 from $179 billion in 2020. Additionally, pharma and biopharma manufacturers' shift from batch to continuous processing and regulatory authorities’ growing focus on continuous bioprocessing are also contributing to the segment’s large market share.

In 2024, North America is expected to account for the largest share of the continuous bioprocessing market. North America's large market share is attributed to the region’s well-established manufacturing base focused on innovating production processes, the rising demand for biopharmaceuticals, government support for the adoption of continuous bioprocessing, and the presence of large biopharmaceutical manufacturers. In February 2020, the U.S. FDA transitioned to a new regulatory pathway to allow biopharmaceutical manufacturers to seek the FDA’s approval for biosimilars to bring them to the market. Additionally, the FDA has approved several drug products manufactured through continuous processes. For instance, at the start of 2022, the FDA approved six finished solid oral drugs produced through continuous manufacturing.

The report offers a competitive landscape based on an extensive assessment of the product offerings and geographic presence of leading market players and the key growth strategies adopted by them over the last 3–4 years (2020–2024). The key players operating in the continuous bioprocessing market include 3M Company (U.S.), Thermo Fisher Scientific, Inc. (U.S.), Sartorius AG (Germany), Eppendorf AG (Germany), Danaher Corporation (U.S.), Merck KGaA (Germany), Repligen Corporation (U.S.), Getinge AB (Sweden), Bionet (Spain), Corning Incorporated (U.S.), Fujifilm Holdings Corporation (Japan), Entegris, Inc. (U.S.), and Meissner Corporation (U.S.).

|

Particulars |

Details |

|

Number of Pages |

~220 |

|

Format |

|

|

Forecast Period |

2024–2031 |

|

Base Year |

2023 |

|

CAGR |

19.6% |

|

Estimated Market Size (Value) |

$1.32 Billion by 2031 |

|

Segments Covered |

By Product

By Process Type

By Application

By End User

|

|

Countries Covered |

North America (U.S. and Canada), Europe (Germany, France, U.K., Italy, Spain, Switzerland, Ireland, Denmark, Belgium, and RoE), Asia-Pacific (China, Japan, India, South Korea, and RoAPAC), Latin America, and the Middle East & Africa |

|

Key Companies Profiled |

3M Company (U.S.), Thermo Fisher Scientific, Inc. (U.S.), Sartorius AG (Germany), Eppendorf AG (Germany), Danaher Corporation (U.S.), Merck KGaA (Germany), Repligen Corporation (U.S.), Getinge AB (Sweden), Bionet (Spain), Corning Incorporated (U.S.), Fujifilm Holdings Corporation (Japan), Entegris, Inc. (U.S.), and Meissner Corporation (U.S.) |

The continuous bioprocessing market study covers products, processes, applications, and end users in the continuous bioprocessing market. This report analyzes various segments of the continuous bioprocessing market at the regional and country levels.

The continuous bioprocessing market is projected to reach $1.32 billion by 2031 at a CAGR of 19.6% from 2024 to 2031.

In 2024, the filtration systems & consumables segment is expected to account for the largest share of the continuous bioprocessing market, mainly due to the growing preference for filtration systems in bioprocessing separation techniques, the reusability of filters across every step in bioprocessing, and the need for high cell densities in controlling the bioburden in biopharmaceuticals.

In 2024, the commercial applications segment is expected to account for the major share of the continuous bioprocessing market, mainly due to increasing investments in constructing facilities compatible with continuous bioprocessing for the commercial manufacture of biopharmaceuticals.

The growth of this market is driven by the rising demand for biopharmaceuticals, the emergence of continuous end-to-end bioprocessing, global initiatives supporting the adoption of biopharmaceuticals, and the advantages of continuous bioprocessing over batch manufacturing.

Furthermore, Bioprocessing 4.0 and the increasing use of continuous bioprocessing for MAB production are expected to offer growth opportunities for the players in this market.

The key players operating in the continuous bioprocessing market are 3M Company (U.S.), Thermo Fisher Scientific, Inc. (U.S.), Sartorius AG (Germany), Eppendorf AG (Germany), Danaher Corporation (U.S.), Merck KGaA (Germany), Repligen Corporation (U.S.), Getinge AB (Sweden), Bionet (Spain), Corning Incorporated (U.S.), Fujifilm Holdings Corporation (Japan), Entegris, Inc. (U.S.), and Meissner Corporation (U.S.).

Emerging countries in Asia-Pacific are expected to offer significant growth opportunities for the vendors in this market due to the evolving landscape of biopharmaceuticals in Asian countries. China and India are among the leading countries in the development and commercialization of biosimilars. The Chinese government has undertaken several initiatives to promote the development and adoption of biosimilars. The development of multinational clinical centers, Accelerated approvals for special medicines, and global sharing of clinical data are some of the initiatives driving the adoption of biosimilars in China.

Published Date: May-2025

Published Date: Jan-2025

Published Date: Jan-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates