Resources

About Us

Specialty Polymers Market by Type (Specialty Thermoplastics, Specialty Elastomers, Specialty Thermosets, Liquid Crystal Polymers), Application (Adhesives & Sealants, Coatings, Composites, Others), and Vertical (Automotive & Transportation, Electrical & Electronics, Aerospace & Defense) – Global Forecast to 2036

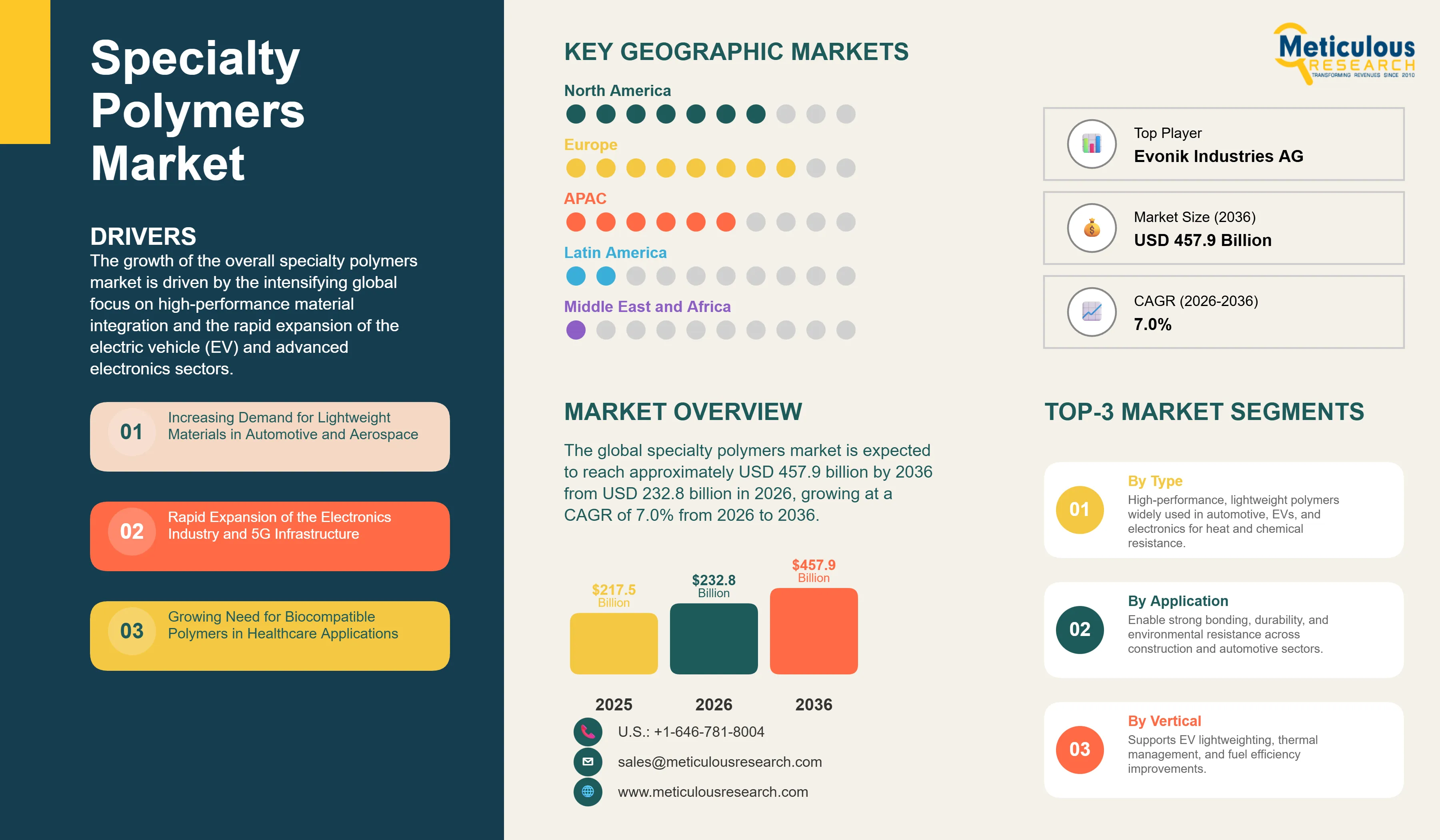

Report ID: MRCHM - 1041740 Pages: 278 Feb-2026 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportThe global specialty polymers market was valued at USD 217.50 billion in 2025. The market is expected to reach approximately USD 457.9 billion by 2036 from USD 232.8 billion in 2026, growing at a CAGR of 7.0% from 2026 to 2036. The growth of the overall specialty polymers market is driven by the intensifying global focus on high-performance material integration and the rapid expansion of the electric vehicle (EV) and advanced electronics sectors. As industrial manufacturers seek to integrate more functionality into lightweighting and heat-resistant material collections, specialty polymer infrastructure has become essential for maintaining high-reliability product performance and brand loyalty. The rapid expansion of global 5G infrastructure and the increasing need for authentic biocompatibility in healthcare demographics continue to fuel significant growth of this market across all major geographic regions.

Click here to: Get Free Sample Pages of this Report

Click here to: Get Free Sample Pages of this Report

Specialty polymers are critical material environments that leverage advanced chemical designs to provide optimized performance experiences and improved product engagement through a connected digital infrastructure. These systems include integrated thermoplastics, high-performance elastomers, and liquid crystal polymers designed to automate material choices and enhance product identity across the industrial continuum. The market is defined by high-efficiency technologies such as AI-powered molecular modeling and blockchain-enabled supply chain tracking, which significantly enhance design precision and resource utilization in high-pressure manufacturing environments. These systems are indispensable for material administrators seeking to optimize their internal operations and meet aggressive performance and sustainability targets.

The market includes a diverse range of solutions, ranging from simple specialty resins for basic product expression to complex bio-based composites and AI-driven personalized material platforms. These systems are increasingly integrated with advanced components such as cloud-based material management and 5G-enabled mobile monitoring to provide services such as real-time property notifications and virtual try-on of polymer-inspired layouts. The ability to provide stable, high-precision design while minimizing production lead times has made specialty polymer technology the choice for brands where material accuracy and operational reliability are paramount.

The global chemical sector is pushing hard to modernize material capabilities, aiming to meet AI-driven design targets and consumer-centric performance goals. This drive has increased the adoption of high-speed digital solutions, with advanced material networks helping to stabilize transaction processing for ultra-high-demand limited edition drops. At the same time, the rapid growth in the renewable energy and wearable technology markets is increasing the need for high-reliability, secure digital solutions.

Chemical houses across the industry are rapidly shifting to specialty-optimized collections, moving well beyond traditional petroleum-based setups toward high-end and bio-based setups. Solvay’s latest bio-sourced platforms deliver significantly higher brand prestige, while Evonik’s recent installations have slashed the barrier between traditional chemistry and high-performance fashion. The real game-changer comes with “generative” material systems featuring integrated natural language processing that maintains peak creative efficiency even in high-volume production environments. These advancements make high-precision polymer collaborations practical and cost-effective for everyone from independent researchers to global chemical conglomerates chasing excellence in consumer appeal and lower operational costs.

Innovation in smart materials and automated manufacturing is rapidly driving the specialty polymers market, as chemical procedures become more precise and facility operations more automated. Brand suppliers like Arkema are now designing units that combine the functionality of daily materials with the intelligence of character-inspired design in a single platform, saving valuable production space and simplifying material logistics. These systems often involve advanced fabric technology and 3D visualization capable of handling complex chemical motifs without compromising user comfort or design reliability.

At the same time, growing focus on sustainable chemistry is pushing manufacturers to develop specialty polymer solutions tailored to eco-friendly and waste reduction principles. These systems help reduce environmental impact through smart supply chain automation and the use of organic or recycled chemical components. By combining high-density design connectivity with robust environmental performance, these new designs support both technological advancement and corporate sustainability, strengthening the resilience of the broader chemical value chain.

|

Parameter |

Details |

|

Market Size by 2036 |

USD 457.9 Billion |

|

Market Size in 2026 |

USD 232.8 Billion |

|

Market Size in 2025 |

USD 217.5 Billion |

|

Market Growth Rate (2026-2036) |

CAGR of 7.0% |

|

Dominating Region |

Asia-Pacific |

|

Fastest Growing Region |

North America |

|

Base Year |

2025 |

|

Forecast Period |

2026 to 2036 |

|

Segments Covered |

Type, Application, Vertical, and Region |

|

Regions Covered |

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

A key driver of the specialty polymers market is the rapid movement of the global automotive industry toward culture-first, consumer-centric models. Global demand for seamless material journeys, real-time property updates, and data-driven collection planning has created significant incentives for the adoption of polymer infrastructure. The trend toward “green mobility” and the integration of material IP into unified digital platforms drive brands toward scalable solutions that specialty polymers can uniquely provide. It is estimated that as consumer adoption of digital-inspired lifestyles rises and design tools become more decentralized through 2036, the need for robust, connected infrastructure increases significantly; therefore, AI-driven software and high-speed connectivity, with their ability to ensure high-density data processing, are considered a crucial enabler of modern material delivery strategies.

The rapid growth of the 5G infrastructure market and virtual material technologies provides great opportunities for the specialty polymers market. Indeed, the global surge in digital asset deployment has created a compelling demand for systems that can handle massive asset throughput and provide ultra-low latency for virtual try-ons. These applications require high reliability, data security, and the ability to handle high-bandwidth visual data, all attributes that are met with advanced polymer solutions. The virtual material market is set to expand significantly through 2036, with specialty polymers poised for an expanding share as brands seek to maximize digital presence and minimize physical production costs. Furthermore, the increasing demand for AI-driven personalization and smart production automation is stimulating demand for modular digital solutions that provide high-speed data transmission and operational flexibility.

The specialty thermoplastics segment accounts for a significant portion of the overall specialty polymers market in 2026. This is mainly attributed to the versatile use of this technology in supporting graphic-heavy designs, mass-market collaborations, and complex character motifs within modern production environments. These systems offer the most comprehensive way to ensure design interoperability across diverse material applications. The automotive and electronics sectors alone consume a large share of polymer-inspired solutions, with major projects in Asia-Pacific and North America demonstrating the technology’s capability to handle high-density data requirements. However, the liquid crystal polymers segment is expected to grow at a rapid CAGR during the forecast period, driven by the growing need for robust implementation, limited edition drops, and technical support in complex material digital transformations.

Based on application, the coatings segment holds the largest share of the overall market in 2026. This is primarily due to the massive volume of protective-themed apparel and the rigorous design standards required for authentic character representation. Current large-scale production systems are increasingly specifying high-density digital platforms to ensure compliance with global IP standards and consumer expectations for high-quality polymer-inspired menswear.

The composites segment is expected to witness the fastest growth during the forecast period. The shift toward lightweight and high-strength themed fashion and the complexity of multi-functional lifestyle collections are pushing the requirement for advanced smart systems that can handle varied style formats and high-resolution designs while ensuring absolute reliability for safety-critical material decisions.

The automotive & transportation segment commands the largest share of the global specialty polymers market in 2026. This dominance stems from its superior ability to process vast amounts of consumer data, provide predictive analytics, and automate routine transaction tasks, making it the channel of choice for high-performance material. Large-scale operations in manufacturing, lightweighting, and personalized marketing drive demand, with advanced algorithms from providers like Solvay and BASF enabling reliable performance in complex production environments.

However, the healthcare segment is poised for steady growth through 2036, fueled by expanding applications in medical devices and experiential retail. Brands face mounting pressure to optimize costs for high-volume, less demanding applications, where healthcare provides a cost-effective alternative for basic consumer connectivity.

Asia-Pacific holds the largest share of the global specialty polymers market in 2026. The largest share of this region is primarily attributed to the deep-rooted manufacturing culture and the presence of the world’s leading chemical innovators, particularly in China. China alone accounts for a significant portion of global polymer investment, with its position as a leading adopter of character-inspired lifestyle driving sustained growth. The presence of leading manufacturers like BASF and a well-developed material supply chain provides a robust market for both standard and high-density smart solutions.

North America and Europe together account for a substantial share of the global specialty polymers market. The growth of these markets is mainly driven by the need for technological modernization in the retail and lifestyle sectors. The demand for advanced smart systems in North America is mainly due to its large-scale aerospace infrastructure projects and the presence of innovators in the U.S. and Canada.

In Europe, the leadership in design engineering and the push for sustainable material innovation are driving the adoption of high-reliability smart solutions. Countries like Germany, France, and the UK are at the forefront, with significant focus on integrating smart digital solutions into material workflows and advanced consumer care systems to ensure the highest levels of performance and reliability.

The companies such as Solvay S.A., BASF SE, Evonik Industries AG, and Arkema S.A. lead the global specialty polymers market with a comprehensive range of digital and design-driven solutions, particularly for large-scale production applications and high-speed fulfillment. Meanwhile, players including Dow Inc., Sabic, Covestro AG, and Ashland Global Holdings Inc. focus on specialized licensed infrastructure, data analytics, and cloud platforms targeting the material operations and administrative sectors. Emerging manufacturers and integrated players such as Victrex plc, Kuraray Co., Ltd., PolyOne Corporation (Avient), and Braskem S.A. are strengthening the market through innovations in collaborative material and modular digital platforms.

The global specialty polymers market is expected to grow from USD 232.8 billion in 2026 to USD 457.9 billion by 2036.

The global specialty polymers market is projected to grow at a CAGR of 7.0% from 2026 to 2036.

Specialty thermoplastics is expected to dominate the market in 2026 due to its superior ability to support graphic-heavy designs and mass-market collaborations. However, the liquid crystal polymers segment is projected to be the fastest-growing segment owing to the increasing need for limited edition drops and technical support in complex material environments.

AI and 5G are transforming the specialty polymers landscape by demanding higher data integrity, lower latency, and improved style decision support. These technologies drive the adoption of advanced platforms like cloud-based inventory management and real-time monitoring systems, enabling material providers to support the complex workflows and high-frequency requirements of next-generation digital supply chains.

Asia-Pacific holds the largest share of the global specialty polymers market in 2026. The largest share of this region is primarily attributed to the deep-rooted manufacturing culture and the presence of leading chemical innovators in China. North America is expected to witness the fastest growth, driven by massive investments in aerospace.

The leading companies include Solvay S.A., BASF SE, Evonik Industries AG, Arkema S.A., and Dow Inc.

Published Date: Jan-2025

Published Date: Apr-2024

Published Date: Oct-2024

Published Date: May-2025

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates