Resources

About Us

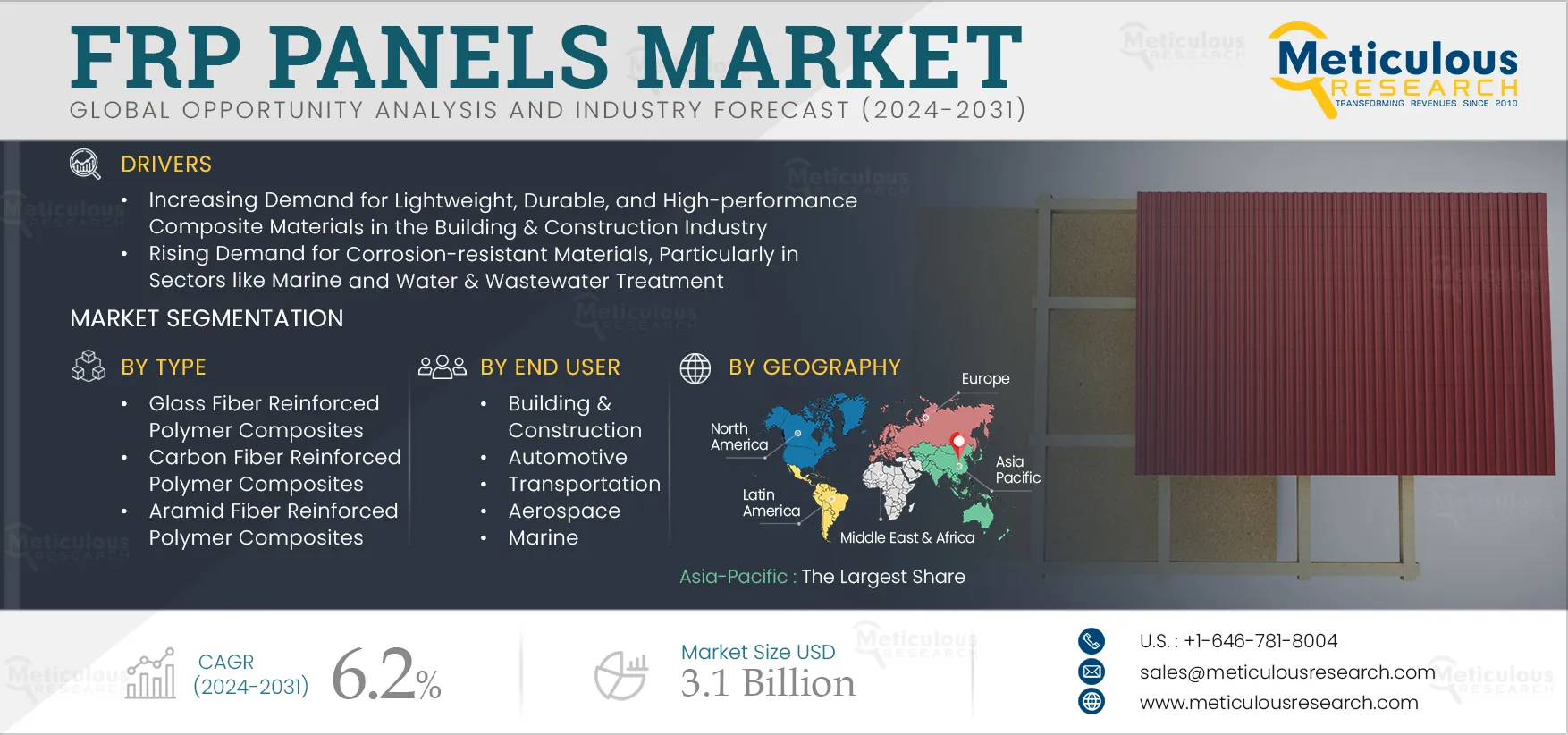

FRP Panels Market Size, Share, Forecast, & Trends Analysis by Type (Glass Fiber Reinforced Polymer Composites, Carbon Fiber Reinforced Polymer Composites), End User (Building & Construction, Automotive, Aerospace), and Geography - Global Forecast to 2032

Report ID: MRCHM - 1041358 Pages: 250 Oct-2024 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportThe growth of the FRP panels market is primarily driven by the increasing demand for lightweight, durable, and high-performance composite materials in the building & construction industry and the rising demand for corrosion-resistant materials, particularly in sectors like marine and water & wastewater treatment. Additionally, the growing adoption of FRP panels in the automotive and aerospace industries, along with continuous advancements in FRP materials, is expected to create growth opportunities for market players.

Key Findings in the FRP Panels Market

Click here to: Get Free Sample Pages of this Report

Fiber reinforced plastics (FRP) are gaining popularity in the building & construction industry due to their unique properties that effectively address challenges faced by traditional materials. FRP comprises a polymer matrix reinforced with fibers, such as glass, carbon, or aramid, which enhances its strength, durability, and versatility.

FRP panels are lightweight, which simplifies handling, transportation, and installation compared to heavier materials like steel or concrete. This reduction in weight can lead to lower labor costs and shorter construction timelines, particularly in large-scale infrastructure projects, such as bridges, tunnels, and buildings. Moreover, the lightweight design of FRP panels is ideal for retrofitting and rehabilitation projects where existing structures may not support the additional load of traditional materials.

Additionally, FRP panels contribute to greener construction practices. Their long lifespan and low maintenance requirements decrease the need for frequent replacements, thus reducing raw material consumption and minimizing waste. Additionally, many FRP products are made from recycled materials, further lowering their environmental impact. FRP panels also possess insulating properties that help maintain consistent indoor temperatures, reducing energy consumption for heating and cooling.

As the building & construction industry increasingly prioritizes sustainable and eco-friendly solutions, FRP panels are poised to play a vital role in delivering innovative, efficient, and resilient building solutions.

The demand for corrosion-resistant materials is increasing, particularly in sectors such as marine and water & wastewater treatment. Traditional materials often face challenges in these environments due to exposure to harsh conditions, including saltwater, chemicals, and fluctuating temperatures. FRP panels are inherently corrosion-resistant, making them an ideal choice for applications where durability and longevity are crucial.

In the marine sector, FRP panels are extensively used for constructing boats, docks, and other structures that come into contact with water. Their lightweight yet strong composition allows for easier handling and reduced transportation costs. This leads to lower maintenance and replacement costs over time, making FRP an economically viable option for boat manufacturers and marina operators.

Similarly, in water & wastewater treatment facilities, FRP panels are increasingly used due to their resistance to chemicals and their capability to withstand the harsh environments often found in these settings. Traditional materials, such as steel or concrete, may deteriorate rapidly under such conditions, leading to frequent repairs and increased operational costs. Thus, FRP panels provide a reliable, low-maintenance alternative that enhances the efficiency and safety of these systems.

As industries seek to enhance performance and sustainability, the demand for corrosion-resistant materials like FRP panels is expected to rise significantly. Therefore, the rising utilization of these panels in the marine and water & wastewater treatment sectors is poised to drive the market’s growth in the coming years.

The automotive and aerospace industries are increasingly integrating FRP panels into their designs. In aerospace, FRP materials are utilized in various components, including fuselage sections, wings, and interior fittings. Their high strength-to-weight ratio not only improves aerodynamics but also reduces operational costs by enhancing fuel efficiency. Similarly, the automotive industry is adopting FRP panels due to their lightweight properties and durability. As manufacturers focus on improving fuel efficiency and reducing emissions, FRP panels provide a crucial solution. Their lightweight design decreases the overall weight of vehicles, enhancing performance and fuel economy without compromising safety.

Based on type, the global FRP panels market is segmented into glass fiber reinforced polymer composites, carbon fiber reinforced polymer composites, aramid fiber reinforced polymer composites, basalt fiber reinforced polymer composites, and other types. In 2025, the glass fiber reinforced polymer composites segment is estimated to account for the largest share of the global FRP panels market. The large market share of this segment is attributed to the increasing demand for GFRP in the automotive industry, the growing adoption of GFRP composites in emerging sectors such as renewable energy and electric vehicles, and a heightened focus on environmental sustainability to reduce the use of hazardous materials. Additionally, market players are actively collaborating to develop advanced FRP solutions. For instance, in May 2025, Crane Composites, Inc. (U.S.), a leading provider of fiberglass reinforced plastic materials, introduced a new premium fiberglass sidewall specifically designed for the recreational vehicle (RV) market.

Glass fiber reinforced polymer (GFRP), commonly referred to as fiberglass, is a composite material formed by combining fine glass fibers with a polymer resin matrix. This composite offers numerous advantages due to its unique properties, making it a versatile choice for a variety of industrial and engineering applications. GFRP is created by embedding high-strength glass fibers within a polymer resin, resulting in a material that boasts remarkable strength and durability.

GFRP is utilized across numerous industries, including construction, aerospace, marine, automotive, and infrastructure. Its diverse applications highlight its adaptability and reliability in demanding environments. In the aerospace sector, GFRP is employed to create lightweight yet strong precision components for aircraft and spacecraft, contributing to improved fuel efficiency and overall performance.

Moreover, the glass fiber reinforced polymer composites segment is projected to register the highest CAGR during the forecast period of 2025 to 2032. The growth of this segment is driven by the benefits offered by glass fiber reinforced polymer composites, including high strength, corrosion resistance, lightweight properties, non-conductivity, electromagnetic transparency, low maintenance requirements, and thermal stability.

In 2025, Asia-Pacific is estimated to account for the largest share of the global FRP panels market. This significant share is primarily attributed to the presence of leading FRP panel providers in the region, the growing adoption of fiberglass-reinforced plastic panels, continuous advancements in FRP material technology, a rise in construction activities, and the increasing demand for lightweight materials across the construction, automotive, and aerospace industries.

Furthermore, key market players are also focusing on expanding their product range, contributing to the market’s growth. For instance, in May 2024, Avient Corporation (U.S.), a leading provider of specialized and sustainable material solutions, expanded its first production line for Complēt and OnForce long fiber reinforced thermoplastic composites in Asia. This new line, installed at Avient’s regional headquarters in Shanghai, aims to meet the increasing demand for composite materials in applications that require excellent impact strength, elastic modulus, and overall material strength.

Moreover, the market in Asia-Pacific is projected to register the highest CAGR during the forecast period. This growth is driven by the rapid economic growth in countries such as China, South Korea, Japan, and India, along with significant infrastructural development across the APAC region. Additionally, the increasing demand for lightweight, durable, and eco-friendly building materials, the rising adoption of modular construction methods, and a growing focus on environmentally friendly FRP panels are contributing to the market’s growth.

The report includes a competitive landscape based on an extensive assessment of the key growth strategies adopted by leading market participants over the past three years (2021-2025). The key players profiled in the global FRP panels market report are Crane Composites, Inc. (U.S.), Fiber-Tech Industries, Inc. (U.S.), POLSER Composite Materials Corporation (Turkey), Nudo Products, Inc. (U.S.), Everest Composites Pvt. Ltd. (India), LAMILUX Heinrich Strunz Holding GmbH & Co. KG (Germany), Vetroresina Spa (Italy), Strongwell Corporation (U.S.), Stabilit America Inc. (U.S.), Enduro Composites (U.S.), Optiplan GmbH (Germany), InPlant Offices Incorporated (U.S.), Panolam Industries International Inc. (U.S.), and Dongguang Higoal FRP Corporation (China).

|

Particulars |

Details |

|

Number of Pages |

250 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

6.2% |

|

Market Size (Value) |

USD 3.1 Billion by 2032 |

|

Segments Covered |

By Type

By End User

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, France, U.K., Italy, Spain, Switzerland, Netherlands, Poland, Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia & New Zealand, Singapore, Indonesia, Rest of Asia-Pacific), Latin America (Mexico, Brazil, Rest of Latin America), and the Middle East & Africa (UAE, Israel, Saudi Arabia, Rest of Middle East & Africa) |

|

Key Companies |

Crane Composites, Inc. (U.S.), Fiber-Tech Industries, Inc. (U.S.), POLSER Composite Materials Corporation (Turkey), Nudo Products, Inc. (U.S.), Everest Composites Pvt. Ltd. (India), LAMILUX Heinrich Strunz Holding GmbH & Co. KG (Germany), Vetroresina Spa (Italy), Strongwell Corporation (U.S.), Stabilit America Inc. (U.S.), Enduro Composites (U.S.), Optiplan GmbH (Germany), InPlant Offices Incorporated (U.S.), Panolam Industries International Inc. (U.S.), and Dongguang Higoal FRP Corporation (China). |

Key questions answered in the report:

The global FRP panels market size was valued at $1.9 billion in 2024.

The market is projected to grow from $2 billion in 2025 to $3.1 billion by 2032.

The analysis of the FRP panels market indicates significant growth, with projections estimating it will reach $3.1 billion by 2032 at a compound annual growth rate (CAGR) of 6.2% from 2025 to 2032.

The key players operating in the FRP panels market are Crane Composites, Inc. (U.S.), Fiber-Tech Industries, Inc. (U.S.), POLSER Composite Materials Corporation (Turkey), Nudo Products, Inc. (U.S.), Everest Composites Pvt. Ltd. (India), LAMILUX Heinrich Strunz Holding GmbH & Co. KG (Germany), Vetroresina Spa (Italy), Strongwell Corporation (U.S.), Stabilit America Inc. (U.S.), Enduro Composites (U.S.), Optiplan GmbH (Germany), InPlant Offices Incorporated (U.S.), Panolam Industries International Inc. (U.S.), and Dongguang Higoal FRP Corporation (China).

A prominent trend in the FRP panels market is the growing adoption of sustainability and eco-friendly materials.

By type, the glass fiber reinforced polymer composites segment is anticipated to hold the largest share of the market during 2025-2032.

By end user, the building & construction segment is anticipated to hold the largest share of the market during 2025-2032.

By geography, Asia-Pacific is anticipated to hold the largest share of the market during 2025-2032.

In 2025, the Asia-Pacific region is expected to hold the largest share of the FRP panels market and is also projected to experience the highest growth rate. This growth is driven by the rapid economic growth in countries such as China, South Korea, Japan, and India, along with significant infrastructural development across the APAC region.

The growth of the FRP panels market is primarily driven by the increasing demand for lightweight, durable, and high-performance composite materials in the building & construction industry and the rising demand for corrosion-resistant materials, particularly in sectors like marine and water & wastewater treatment.

Published Date: Oct-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates