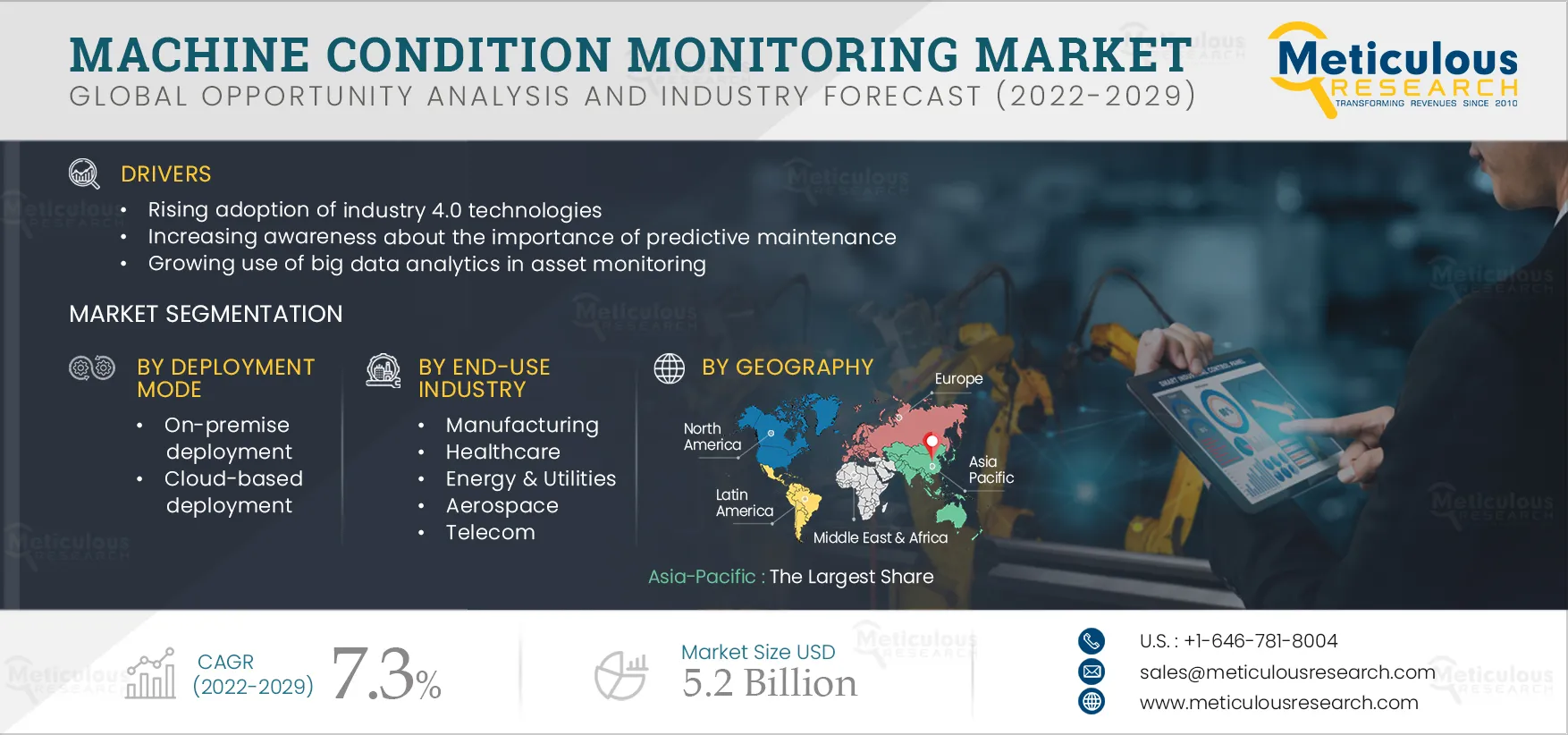

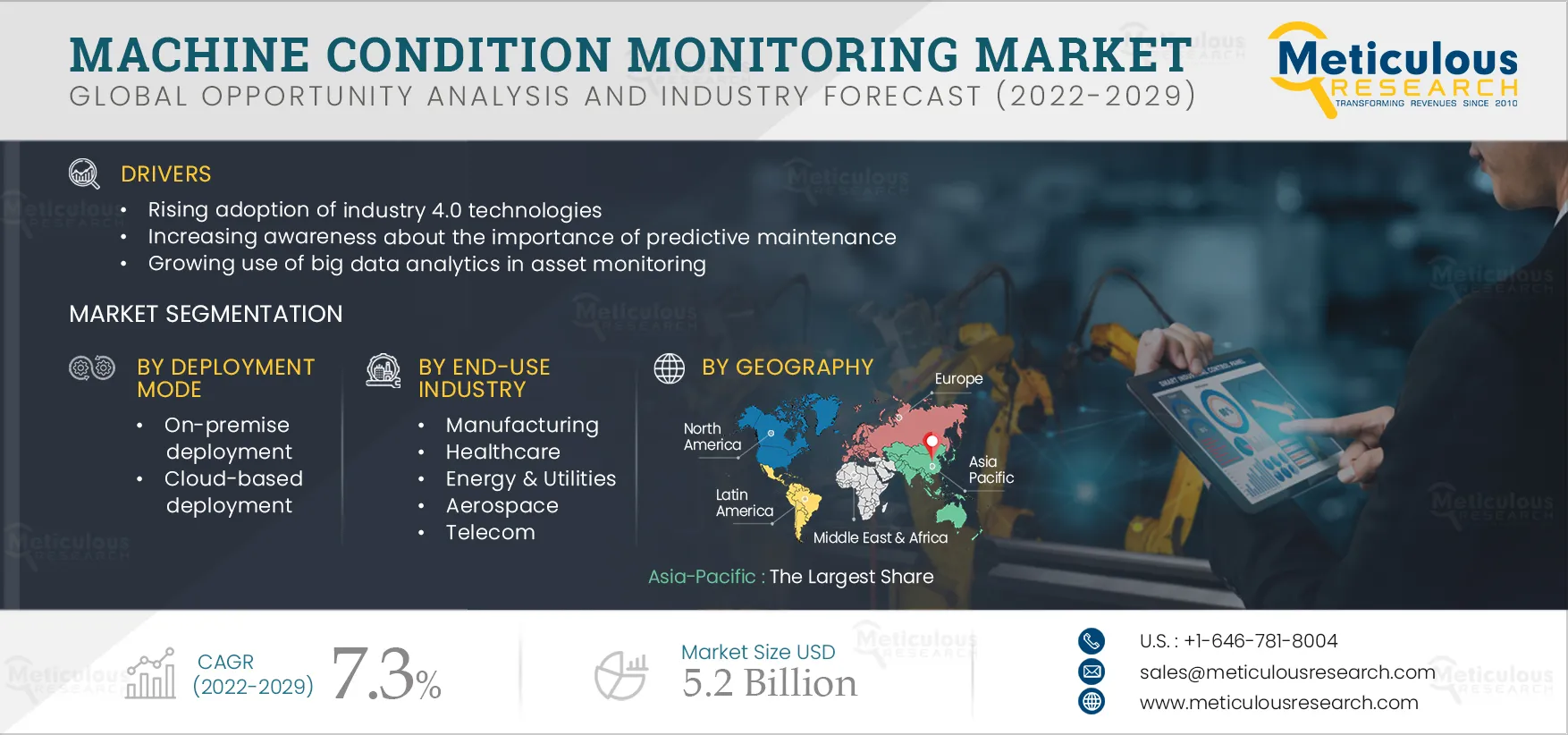

The Machine Condition Monitoring Market is expected to reach $5.2 billion by 2029, at a CAGR of 7.3% during the forecast period 2022–2029. The growth of this market is driven by the rising adoption of Industry 4.0 technologies and the growing use of big data analytics in asset monitoring. However, a shortage of technical expertise for analyzing & predicting machine condition may restrain the growth of this market. Additionally, the rising focus on reducing human intervention in predictive maintenance is expected to create significant growth opportunities for the stakeholders in this market. However, the high cost & complexities of integrating machine monitoring systems with existing infrastructure is expected to pose a challenge to market growth.

Impact of COVID-19 on the Machine Condition Monitoring Market

The outbreak of the COVID-19 pandemic in the first quarter of 2020 led to a widespread economic downturn as several countries imposed strict lockdowns to contain the infection. The COVID-19 pandemic adversely hit many economies around the globe. The combat measures, such as complete lockdowns and travel restrictions, impacted various industries such as manufacturing and oil & gas. The lockdown slowed the growth of the global machine condition monitoring market due to a reduction in the overall production capacity of various industries.

The COVID-19 pandemic affected the industrial sector, especially manufacturing operations. However, there is increasing adoption of advanced technologies, such as sensors, machine learning, and IoT, to lessen the cost of shutting down plants due to lockdowns and reduce human intervention. This increased the need to ensure that the equipment runs efficiently for future-proof operations. The machine condition monitoring systems help gain insights from real-time data sources to optimize & maintain equipment and prevent downtime. Such measures are increasing the deployment of new machine condition monitoring systems in various manufacturing plants and helping to recover the machine condition monitoring market.

Click here to: Get Free Sample Copy of this report

Adoption of Advanced Technologies in Industry 4.0 Driving the Growth of Machine Condition Monitoring Market

Industry 4.0 focuses on automation, machine learning, and real-time data processing to automate manufacturing plant processes. This has increased the deployment of automated manufacturing technologies such as automation, data analytics, and industrial IoT to improve operational efficiencies. Additionally, in Industry 4.0, the adoption of predictive maintenance offers significant opportunities for various industries. The machine condition monitoring process involves monitoring machine data to detect and schedule repairs and reduce downtime. Such advancement allows for analyzing equipment performance and predicting failure scenarios. Thus, increasing awareness regarding machine condition monitoring is expected to provide opportunities for market growth.

Key Findings in the Global Machine Condition Monitoring Market Study:

In 2022, the Software Segment to Account for the Largest Share of the Machine Condition Monitoring Market

Based on component, the market is segmented into hardware, software, and services. In 2022, the software segment is expected to account for the largest share of the global machine condition monitoring market. The large market share of this segment is attributed to the increasing use of machine condition monitoring software to reduce downtime, boost productivity, increase efficiency, and make accurate predictions related to production. Additionally, this segment is slated to register the highest CAGR during the forecast period.

The Cloud-based Deployment Segment to Register the Higher CAGR During the Forecast Period

Based on deployment mode, the cloud-based deployment segment is slated to register the higher CAGR during the forecast period. The adoption of cloud-based machine condition monitoring is gaining popularity across industrial sectors. Several companies are increasingly adopting cloud-based services, and this trend is expected to grow in the coming years. The benefits offered by cloud infrastructure, such as ease of adoption, privacy, cost saving, and easy installation of security solutions, support the growth of this segment.

In 2022, the Vibration Monitoring Segment to Register the Largest Share of the Machine Condition Monitoring Market

Based on monitoring technique, the market is segmented into vibration monitoring, corrosion monitoring, thermography, oil analysis, ultrasound monitoring, and other monitoring techniques. In 2022, the vibration monitoring segment is expected to account for the largest share of the global machine condition monitoring market. The large market share of this segment is attributed to the increasing use of vibration monitoring techniques in manufacturing plants to diagnose machine conditions and detect faults in machine operations.

In 2022, the Manufacturing Segment to Dominate the Machine Condition Monitoring Market

Based on end-use industry, the market is segmented into manufacturing, healthcare, energy & utilities, aerospace, telecom, agriculture, oil & gas, transportation & logistics, and other end-use industries. In 2022, the manufacturing segment is expected to account for the largest share of the global machine condition monitoring market. The large market share of this segment is attributed to government initiatives to promote industrial automation, rising investments in Industry 4.0 technologies, and increasing demand for predictive maintenance. Additionally, this segment is slated to register the highest CAGR during the forecast period.

In 2022, Asia-Pacific is Expected to Account for the Largest Share of the Global Machine Condition Monitoring Market

Based on geography, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. In 2022, Asia-Pacific is expected to account for the largest share of the global machine condition monitoring market. The large market share of this segment is attributed to the rising demand for automation, the high growth in industrial robot deployment, and the presence of high-production countries such as China and Japan. Also, the region is slated to register the highest CAGR during the forecast period.

Key Players

The report includes key strategic developments adopted by the leading market participants in the machine condition monitoring market over the last three years.The key players operating in the global machine condition monitoring market are General Electric Company (U.S.), AB SKF (Sweden), Wilcoxon Sensing Technologies (U.S.), Emerson Electric Co. (U.S.), ALS Limited (Australia), Honeywell International Inc. (U.S.), Parker-Hannifin Corporation (U.S.), Rockwell Automation, Inc. (U.S.), ifm electronic gmbh (Germany), Schaeffler AG (Germany), Baker Hughes Company (U.S.), Analog Devices, Inc. (U.S.), Fluke Corporation (U.S.), Meggitt PLC (U.K.), and National Instruments Corporation (U.S.).

Scope of the Report:

Machine Condition Monitoring Market, by Component

- Hardware

- Sensors

- Analyzers

- Other Hardware

- Software

- Services

Machine Condition Monitoring Market, by Deployment Mode

- On-premise deployment

- Cloud-based deployment

Machine Condition Monitoring Market, by Monitoring Process

- Online Monitoring

- Portable Monitoring

Machine Condition Monitoring Market, by Monitoring Technique

- Vibration Monitoring

- Corrosion Monitoring

- Thermography

- Oil Analysis

- Ultrasound Monitoring

- Other Monitoring Techniques

Machine Condition Monitoring Market, by End-use Industry

- Manufacturing

- Healthcare

- Energy & Utilities

- Aerospace

- Telecom

- Agriculture

- Oil & Gas

- Transportation & Logistics

- Other End-use Industries

Machine Condition Monitoring Market, by Geography

- North America

- Europe

- U.K.

- Germany

- France

- Italy

- Spain

- Rest of Europe

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Singapore

- Rest of Asia-Pacific

- Latin America

- Middle East & Africa

Key questions answered in the report: