Resources

About Us

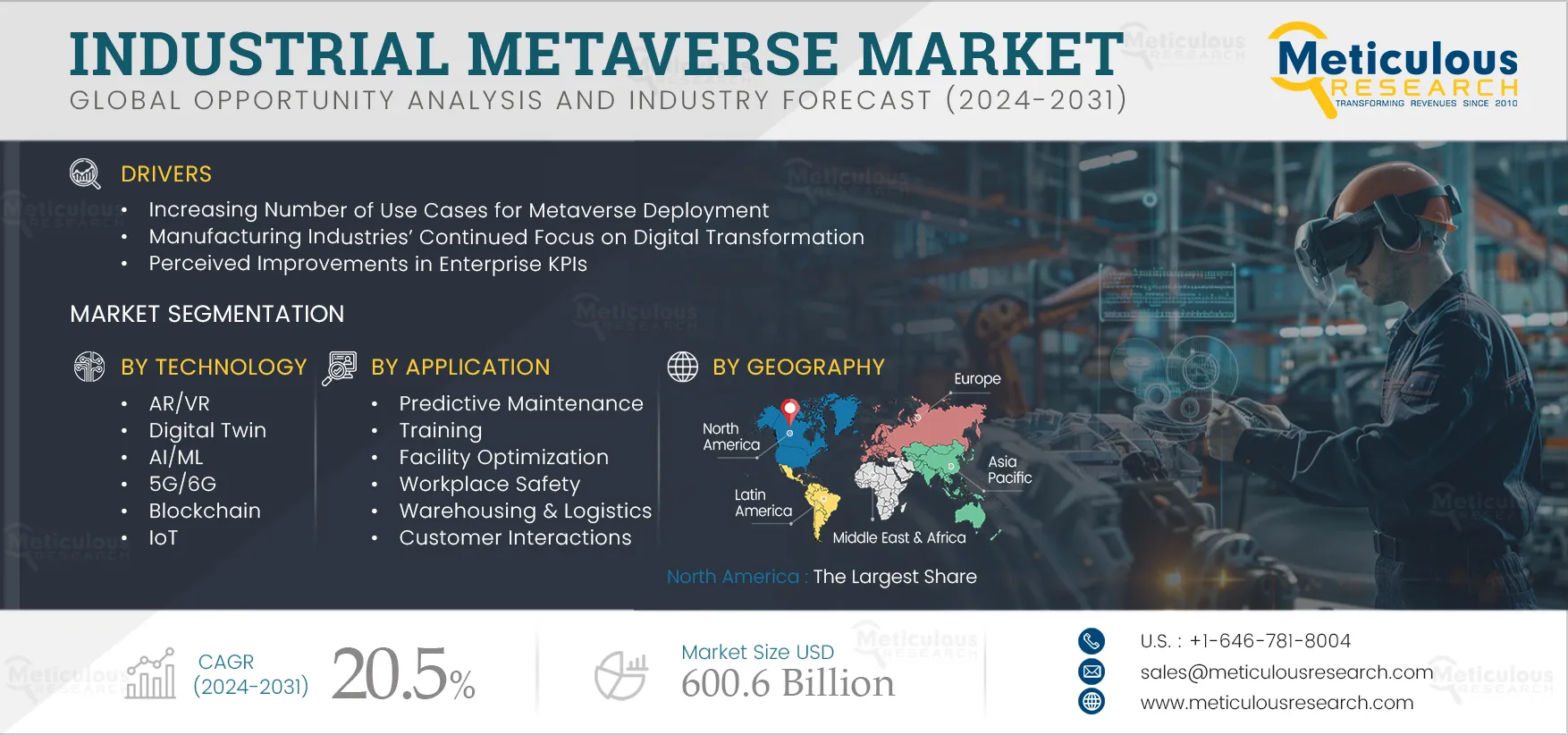

Industrial Metaverse Market Size, Share, Forecast, & Trends Analysis by Technology (AR/VR, Digital Twin, Autonomous Robots, Cloud Computing, AI/ML, 5G/6G, Blockchain, IoT, Location Services, Edge Computing, Exoskeleton), Application, End-use Industry - Global Forecast to 2032

Report ID: MRICT - 1041318 Pages: 300 Sep-2024 Formats*: PDF Category: Information and Communications Technology Delivery: 24 to 72 Hours Download Free Sample ReportThe growth of the industrial metaverse market is attributed to the increasing use cases for metaverse deployment, manufacturing industries’ growing focus on digital transformation, and improvements in enterprise KPIs. Furthermore, organizations’ growing need to reduce operational expenditure and enable collaborative and immersive product design & development is expected to generate growth opportunities for the players operating in this market.

Manufacturing industries are adopting new-age technologies to drive innovation, enhance efficiency, and stay competitive in the dynamic market landscape. Industrial metaverse adoption is the latest frontier in the digital evolution of manufacturing industries.

Stakeholders in the manufacturing sector are closely monitoring the emergence of technologies such as avatars, digital twins, smart devices, and wearables. These technologies have the potential to increase production efficiency while optimizing costs and reducing risks through predictive & prescriptive analytics. Advanced technologies such as digital twins, robotics, Augmented Reality (AR), Virtual Reality (VR), and Mixed Reality (MR) hold immense potential for the manufacturing sector as they can bridge the gap between the physical & virtual worlds and promote collaboration among geographically dispersed teams in real time.

For instance, Boeing pioneered the use of the industrial metaverse to revolutionize its next-generation airplanes. By integrating design, production, and airline service operations within the metaverse, Boeing aimed to address approximately 70% of the quality issues stemming from design problems. This innovative use of the metaverse to simulate every possible scenario before production is a testament to the transformative power of digital transformation among manufacturing industries.

Click here to: Get Free Sample Pages of this Report

Click here to: Get Free Sample Pages of this Report

The industrial metaverse enhances the visualization of intricate manufacturing processes & equipment while also enabling the training of employees in a safe & controlled environment. Metaverse technology is revolutionizing how individuals and organizations interact across production, procurement, sales, consumption, education, and collaboration environments. This shift has brought substantial benefits to the manufacturing sector by enabling effective monitoring and enhancing Key Performance Indicators (KPIs). By leveraging the industrial metaverse, manufacturers can optimize production, lower costs, and boost overall efficiency.

Some of the key improvements brought by the industrial metaverse in manufacturing KPIs are as follows:

Such benefits of the industrial metaverse in improving manufacturing KPIs are anticipated to support the growth of the industrial metaverse market during the forecast period.

The industrial metaverse utilizes real-time data. Analyzing large volumes of data becomes essential for manufacturers using metaverse technologies such as Augmented Reality (AR) and digital twins for workforce training. Continuous simulation can leverage this real-time data from digital twins and human-machine interfaces to continuously evaluate ‘what if’ scenarios in production, which enables plant & maintenance managers to generate contingency plans or alternative processes based on the ongoing simulations of scenarios.

Continuous simulations facilitate the ongoing optimization of stable systems by incorporating inputs and configurations. These simulations can either be fully automated or be activated by specific real-world conditions to identify improvements passively or target specific goals or KPIs. Continuous simulations have the potential to bridge digital transformation, real-time analytics, and predictive AI/ML, making them a valuable tool for manufacturers committed to continuous improvement.

The industrial metaverse can enable collaborative and immersive design & development, allowing businesses across diverse sectors to stay competitive and foster innovation. The industrial metaverse can create immersive virtual environments that mirror real-world manufacturing processes with the help of technologies such as AR/VR, mixed reality, and digital twins, enabling engineers, designers, and stakeholders to overcome physical barriers and allowing them to collaborate from any location.

The industrial metaverse facilitates collaborative design & development workflows by connecting remote teams in a virtual environment for brainstorming ideas, iterating on designs, and visualizing concepts in a 3D space.

The metaverse helps enterprises refine product designs, optimize manufacturing processes, and conduct virtual assembly simulations, significantly enhancing the design & development process.

Automotive manufacturers incorporate virtual reality simulations to refine vehicle designs, simulate crash tests, and optimize manufacturing workflows, while aerospace companies use digital twins to simulate aircraft performance, conduct virtual maintenance procedures, and enhance pilot training, and consumer goods companies use the metaverse to create immersive shopping experiences and gather feedback on product prototypes.

Based on technology, the industrial metaverse market is segmented into AR/VR, digital twin, autonomous robots, cloud computing, AI/ML, 5G/6G, blockchain, IoT, location services, edge computing, exoskeleton, and quantum computing. In 2025, the cloud computing segment is expected to account for the largest share of over 18.0% of the industrial metaverse market. The segment’s large market share is attributed to the ability of cloud computing to provide on-demand delivery of IT resources over the Internet with pay-as-you-go pricing instead of needing to buy, own, and maintain physical servers, the high operational efficiencies while hosting the industrial metaverse using cloud computing, and the use of cloud computing to reduce outages by bringing resources closer to users and safeguarding personal information.

However, the quantum computing segment is projected to register the highest CAGR of 22.4% during the forecast period 2025–2032. The growth of this segment is driven by quantum computing's ability to revolutionize the industrial metaverse, ensure highly accurate and efficient simulation and modeling of complex systems, and excel in solving optimization problems in manufacturing and supply chain management.

Moreover, quantum computing can accelerate ML & AI algorithms, enabling more sophisticated data analysis, pattern recognition, and predictive modeling within the industrial metaverse.

Based on application, the industrial metaverse market is segmented into prototyping, testing, and simulation, predictive maintenance, training, facility optimization, research & development, workplace safety, warehousing & logistics, customer interactions, and other applications. In 2025, the prototyping, testing, and simulation segment is expected to account for the largest share of 33.2% of the industrial metaverse market. The segment’s large share is attributed to the benefits of the industrial metaverse in prototyping, testing, and simulation applications, such as accelerated product development cycles, reduced chances of costly errors, an agile approach toward product development, and real-time collaborations between geographically dispersed teams in real time.

Based on end-use industry, the industrial metaverse market is segmented into automotive, industrial goods & manufacturing, power & utilities, transportation, supply chain & logistics, and other end-use industries. In 2025, the industrial goods & manufacturing segment is expected to account for the largest share of over 28% of the industrial metaverse market. The segment’s large market share is attributed to the complex product development processes, reliance on simulation and testing, and the need for continuous innovation in the industrial goods & manufacturing sectors.

However, the power & utilities segment is expected to register the highest CAGR of 30.0% during the forecast period 2025–2032.

The metaverse enhances energy infrastructure planning for power & utility companies, optimizing systems ranging from power plants to distribution networks and reducing energy waste. Digital twins enable remote monitoring and predictive maintenance, boosting operational efficiency and minimizing on-site visits. Spatial computing supports virtual training environments, mitigating the risks of on-site training for nuclear power plants. Blockchain technology is instrumental in tracking green energy sources from origin to consumption, simplifying the assessment of sustainability progress.

Based on geography, the industrial metaverse market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2025, North America is expected to account for the largest share of over 36% of the industrial metaverse market, followed by Europe, Asia-Pacific, Latin America, and the Middle East & Africa. North America’s large market share is attributed to the high number of industrial metaverse use cases in the region.

Large MNCs such as Tesla, Ford, and Dow Chemicals have implemented various IoT, AI/ML, and AR/VR-based solutions for improving plant efficiency, identifying opportunities for improvement, and enabling predictive maintenance and quality control.

Ford Motors, in association with Bosch, developed a virtual VR-based automotive service training solution for its all-electric Mustang Mach-E SUV. The solution enabled Ford technicians to diagnose, learn about, and operate the vehicle’s components remotely in an immersive simulated world using a VR headset.

However, Asia-Pacific is slated to register the highest CAGR of 25.6% during the forecast period. The growth of this regional market is driven by Asia-Pacific’s high ranking in most active industrial and enterprise metaverse applications. Also, organizations in Asia-Pacific are increasingly integrating the industrial metaverse into their processes and manufacturing facilities, enabling them to better optimize processes and improve efficiencies.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last three to four years. Some of the key players operating in the industrial metaverse market are ABB Ltd. (Switzerland), Siemens AG (Germany), IBM Corporation (U.S.), Robert Bosch GmbH (Germany), Oracle Corporation (U.S.), Microsoft Corporation (U.S.), Nvidia Corporation (U.S.), Cisco Systems, Inc. (U.S.), Dassault Systèmes SE (France), Altair Engineering Inc. (U.S.), PTC Inc. (U.S.), Intel Corporation (U.S.), Penguin Solutions (U.S.), SAP SE (Germany), and Arm Limited (U.K.).

|

Particulars |

Details |

|

Number of Pages |

300 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

20.5% |

|

Market Size (Value) |

$600.6 Billion by 2032 |

|

Segments Covered |

By Technology

By Application

By End-use Industry

|

|

Countries Covered |

Europe (France, Germany, U.K., Italy, Spain, and Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Taiwan, and Rest of Asia-Pacific), North America (U.S. and Canada), Latin America, and the Middle East & Africa |

|

Key Companies Profiled |

ABB Ltd. (Switzerland), Siemens AG (Germany), IBM Corporation (U.S.), Robert Bosch GmbH (Germany), Oracle Corporation (U.S.), Microsoft Corporation (U.S.), Nvidia Corporation (U.S.), Cisco Systems, Inc. (U.S.), Dassault Systèmes SE (France), Altair Engineering Inc. (U.S.), PTC Inc. (U.S.), Intel Corporation (U.S.), Penguin Solutions (U.S.), SAP SE (Germany), and Arm Limited (U.K.) |

The industrial metaverse market study focuses on opportunity assessment and industry forecasts based on the sales of industrial metaverse solutions across various segments, regions, and countries. The report also includes a competitive analysis based on leading market players’ product portfolios, geographic presence, and key growth strategies adopted over the past 3–4 years.

The industrial metaverse market is projected to reach $600.6 billion by 2032, at a CAGR of 20.5% during the forecast period.

The cloud computing segment is expected to account for the largest share of the industrial metaverse market in 2025.

The prototyping, testing, and simulation segment is expected to account for the largest share of over 28% of the industrial metaverse market in 2025.

The growth of the industrial metaverse market is attributed to the increasing use cases for metaverse deployment, manufacturing industries’ growing focus on digital transformation, and improvements in enterprise KPIs. Furthermore, organizations’ growing need to reduce operational expenditure and enable collaborative and immersive product design & development is expected to generate growth opportunities for the players operating in this market.

The key players operating in the industrial metaverse market are ABB Ltd. (Switzerland), Siemens AG (Germany), IBM Corporation (U.S.), Robert Bosch GmbH (Germany), Oracle Corporation (U.S.), Microsoft Corporation (U.S.), Nvidia Corporation (U.S.), Cisco Systems, Inc. (U.S.), Dassault Systèmes SE (France), Altair Engineering Inc. (U.S.), PTC Inc. (U.S.), Intel Corporation (U.S.), Penguin Solutions (U.S.), SAP SE (Germany), and Arm Limited (U.K.).

Asia-Pacific is expected to register the highest CAGR of 25.6% during the forecast period.

Published Date: Jan-2025

Published Date: Jan-2025

Published Date: Jul-2024

Published Date: Jan-2025

Published Date: Feb-2025

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates